Artificial lift oil recovery method is a method of artificially replenishing energy to the bottom of an oil well and lifting oil from the reservoir to the wellhead. It is a key technical link in oil recovery engineering. After decades of development, a number of lifting technologies such as oil pumps, screw pumps, electric submersible pumps, and air lifts have been formed to meet the needs of conventional oil recovery, but at the same time there are also a series of problems such as low efficiency, high energy consumption, and short pump inspection cycles. In recent years, the field of unconventional oil and gas extraction has been very lively, and the difficulty of extracting oil and gas reservoirs has also increased. In the face of increasingly complex oil well lifting conditions and rising oil production costs, efficient and low-cost artificial lift technology has also become the research focus of major oil service companies.

These problems have prompted artificial lift to develop in a more efficient, energy-saving, environmentally friendly and reliable direction. In the research and development process of artificial lift technology, different oil well lifting problems should be combined, and targeted technical research should be carried out to improve the lifting technology in order to improve the level of monitoring and diagnosis of lifting working conditions, and realize the purpose of artificial lift to improve efficiency and reduce costs.

There are many kinds of artificial lift technologies, and the major oil service companies have their own merits in the field of artificial lift. Combined with the current development situation in the field of artificial lift, today we mainly choose the following artificial lift methods to introduce.

Pumping unit:

The oil pumping unit is the most important lifting equipment in the rod pumping system and has a history of nearly a hundred years. According to whether there is a traveling beam, it can be divided into a traveling beam type pumping unit and a non-traveling beam type pumping unit, of which the traveling beam type pumping unit has always occupied a dominant position. Relying on the characteristics of simple structure, strong and reliable, the oil pumping unit has always occupied the dominant position of artificial lift. In recent decades, the world's demand for crude oil has been increasing, and there have been further requirements for the ability of oil fields to be deeply mined. To a large extent, the speed of technological development of pumping units has been accelerated, and various types have been spawned.

In the development process of oil pumping units, they are also facing many problems, such as the decline in mining efficiency in the middle and late stages, the low degree of product serialization, standardization, and generalization, and the low work efficiency and energy utilization rate. In recent years, research on oil pumping units has been continuous. The main features are: enhanced reliability and economy; Improved work performance and smoother operation; Improved work efficiency and more energy-saving; Expanded the scope of use and reduced the requirements for the working environment; Adopted intelligent modular design; Improved automation and intelligence, and strengthened remote control and automatic monitoring capabilities.

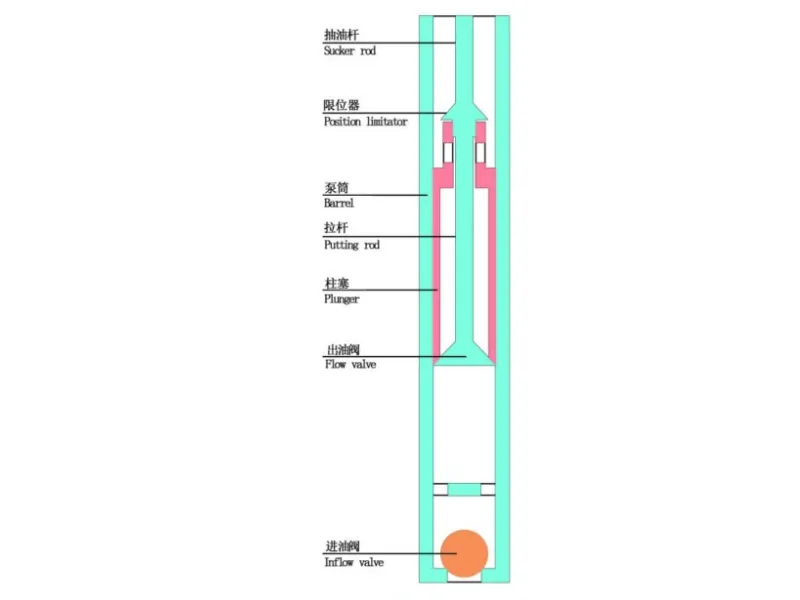

Plunger lift:

Plunger lifting is mainly used in gas wells. It is a reciprocating piston pump with high efficiency and high head. It can be adapted to straight wells, oblique wells, cluster wells, horizontal wells, etc.This lifting system can effectively eliminate effusion at the bottom of the well, reduce the back pressure on the production layer, prevent flooding, and thereby extend the life of natural gas wells.

Plunger lifting has the characteristics of simple equipment, low investment and low operating costs. It has become the preferred mining method for high oil-to-gas ratio and low-capacity oil wells, and it has also become an ideal replacement method for continuous gas lifting wells. At the same time, it is also very economical and reliable for the drainage and gas extraction of gas wells.

However, the traditional plunger lifting system will interrupt production when the plunger drops. The longer the plunger drops, the more production will lag, which reduces the oil recovery efficiency to a certain extent. R&D personnel have been looking for solutions to this problem and have achieved certain results.

Electric submersible twin screw pump:

Because of its advantages of low energy consumption and small footprint, electric submersible screw pumps have gained rapid promotion in the oil production industry due to their unique advantages in horizontal, inclined, and sand-bearing well mining. Compared with single-rotor screw pumps, twin-screw pumps with dual rotors are a relatively emerging concept, and they also provide a new idea for the research and development of new underground mechanical oil production equipment at home and abroad.

The twin-screw pump oil recovery system can be divided into two types: Ground mechanical drive and underground submersible motor drive. The downhole submersible motor-driven twin-screw pump system is similar to the electric submersible screw pump (ESPCP) oil recovery system, except that the centrifugal pump assembly is replaced with a twin-screw pump assembly, that is, the main components from the bottom of the well are “submersible motor →protector→ twin-screw pump body”, the pump body part is connected to the lower end of the oil pipe, which is the core part of the complete set of equipment. Twin-screw pumps have many advantages over screw pumps, and their applications are becoming more and more extensive.

The importance of artificial lift equipment is self-evident, and it is directly related to the profitability of operators. The research of major service companies on artificial lift has never stopped. Artificial lift equipment is essential in oil and gas extraction. Whether it is conventional oil reservoirs or unconventional oil and gas, it is inseparable from artificial lift equipment. At present, oil prices are still depressed. How to improve the efficiency of oil production and reduce costs is a difficult problem faced by major companies.