Like all artificial lift systems, API rod pumps are used to restore production when the reservoir's natural driving energy is insufficient to bring oil and gas to the surface. Operators are now applying this proven technology to unconventional resources that have only recently become economically and technically viable.

The oil and gas industry recognizes that shale reservoirs vary, and the majority of shale well production comes from the fractured stages. Initially, high bottomhole pressures provide sufficient energy to lift oil and gas from the stimulated zones to the surface. However, fluid flow rates and pressures decline over time, necessitating the installation of artificial lift systems. Regardless of the type of system chosen, installing artificial lift systems in shale fields located outside conventional oil-bearing zones typically requires significant investment.

To improve return on investment, operators are employing various strategies.

These strategies are based on the established fact that shale well production declines during the early stages of production. Because artificial lift systems can meet the initial high production requirements of shale wells, some operators choose to implement them during the initial production phase, replacing them with lower-rate systems as production declines.

Other operators choose to forgo initial high production rates in favor of systems that remain cost-effective even after production declines. API rod pump systems are often chosen because they can effectively lift fluids from greater well depths and accommodate a wide range of production rates and wellbore conditions. Operators may install API rod pumps during initial production or when production declines to the point where high-rate systems are less effective.

Why Choose an API Rod Pump System?

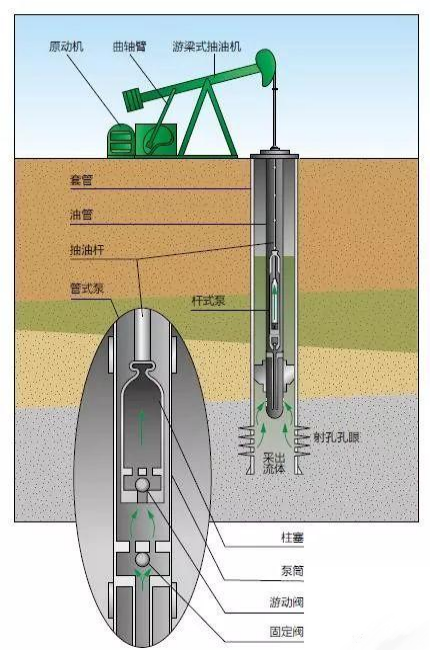

Operators choose API rod pump systems for many reasons. API rod pumps have a long history in the oil and gas industry, and engineers are familiar with the technology. They are generally considered reliable, cost-effective, and easy to install and maintain. The API rod pump is the most common artificial lift system, consisting of a prime mover, surface pumping unit, sucker rod string, and downhole pump. The prime mover, driven by an internal combustion engine or electric motor, transmits power to a speed reducer, which then drives the surface pumping unit. The crank arm on the surface pumping rig reciprocates the walking beam, driving the sucker rod string mounted at the other end of the walking beam up and down. This rod string movement allows the downhole pump's traveling ball valve and stationary ball valve to capture fluid or release it into the tubing. In some API rod pump configurations, the ball valve is part of the API rod pump—an integrated assembly—allowing the rod recovery assembly to hold the tubing stationary.

A walking beam pumping system. As the traveling ball valve at the end of the sucker rod string moves downward in the fluid column, the ball is pushed off the valve seat. When the traveling valve reaches its lowest point, the walking beam is at its lowest point. The walking beam then begins to move upward, pulling the sucker rod upward and forcing the ball in the traveling valve back onto its seat, capturing the fluid column above it (green). As fluid is pumped to the surface, reservoir pressure exceeds the pressure in the pump chamber, forcing the ball in the stationary valve off its seat. Formation fluid (green arrows) flows through the stationary valve below, filling the pump chamber. When the traveling valve begins to descend, the fluid column pressure forces the ball in the fixed valve back onto its seat, allowing the pump to circulate back and forth.

In vertical wells, operators install API rod pumps below the perforated section to address gas interference. This creates a natural gravity-based gas-liquid separator, allowing free gas to migrate upward from the perforated section, while the denser liquid flows into the casing-tubing annulus surrounding the API rod pump. However, in horizontal wells, because the API rod pump is installed above the perforated section, when the API rod pump's suction pressure is below the bubble point and the gas-liquid ratio is high, the fluid flowing into the API rod pump may appear foamy.

In shale wells, operators install a gas-liquid separator at the bottom of the API rod pump downhole to isolate the pump from the produced fluid. The gas-liquid separator directs liquid into the API rod pump and discharges gas. When the pressure at the high point in the annulus is low, free gas separates from the liquid and migrates upward, while the liquid containing the gas flows downward into the API rod pump's suction port.

Packer-type gas-liquid separator. A packer-type gas-liquid separator is installed directly on the tubing above the packer, forcing all formation fluids to flow through the separator before entering the API rod pump inlet. Formation fluid (black arrows) migrates within the tubing, passes through the separator's perforated joint, and enters the annulus between the inner and outer tubing. From there, it flows back through slots in the outer tubing to the annulus between the casing and the outer tubing above the packer. This flow path creates a low-pressure, turbulent flow, allowing gas to desorb from the fluid. The desorbed free gas exits the downhole pump inlet and migrates upward along the tubing-casing annulus.

In many cases, particularly in the presence of foamy fluids, the gas-liquid separator is unable to eliminate the effects of gas interference, resulting in a portion of gas remaining in the API rod pump during each cycle. This condition is easily identified using a dynamometer diagram depicting the relationship between pump rod force and displacement.

After more than a decade of rapid drilling and production, most shale formations still require operators and service companies to understand their natural characteristics. Drilling and completion engineers continue to focus on optimizing wellbore geometry, well spacing, and fracture design. However, in the early stages of shale resource exploration and development, establishing methods to optimize shale formation production received relatively little attention.

As the shale development environment evolves, operators' priorities are also shifting. Current oil prices are very low, and most of the best shale plays are already developed. Therefore, investing in drilling and fracking numerous wells in oil and gas fields to continuously produce from extremely low permeability reservoirs is no longer feasible.

Instead, operators may be able to increase their return on investment by improving well completion and production practices. This approach has proven to be more practical. Some experts believe that 95% of shale oil in place remains untapped, and much of this untapped shale oil can be recovered from already drilled and fractured wells.