I. Overview of the Inclined Well Sucker Rod Pump:

During oilfield production, due to formation structure and specific conditions, oil well pumps operate in wells with a certain inclination. Using conventional pumps can cause valve closure lag, resulting in lower pump efficiency and increased production costs. To address this issue, we developed the inclined well sucker rod pump, which addresses the issue of valve ball closure lag and improves pump efficiency.

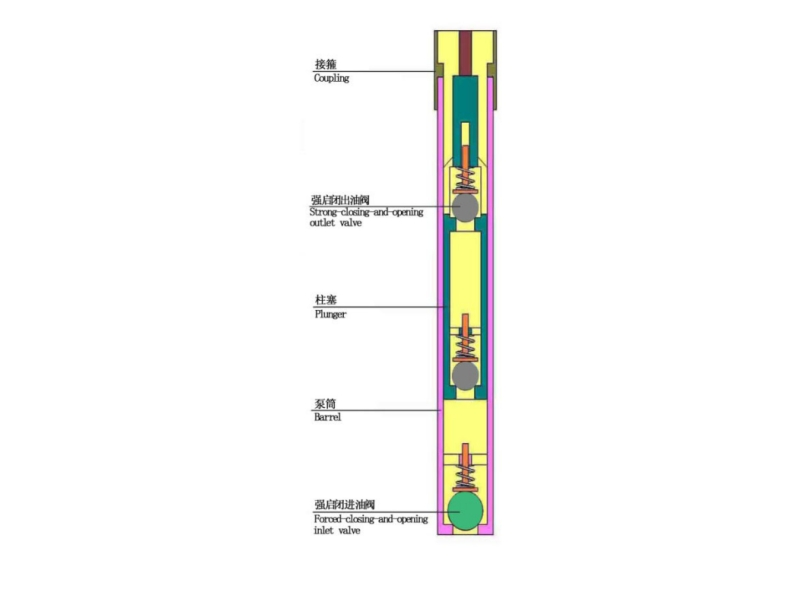

II. Structural Features and Principles of the Inclined Well Sucker Rod Pump:

The inclined well sucker rod pump consists of a pump cylinder assembly, a special floating valve plunger assembly, and a special fixed valve assembly. Its features include:

1. It relies on spring force to force the valve ball closed.

2. The valve ball cover and spring provide centering, ensuring excellent alignment.

3. It solves the problems of valve ball closure lag and valve ball deflection during pumping in inclined wells, extending the pump's lifespan and efficiency. It is suitable for both inclined and horizontal wells. 4. We offer stainless steel and carbide valve balls and seats, depending on user needs. The operating principle is the same as for conventional oil well pumps.

III. Preparation and Operation Before Lowering the Inclined Well Sucker Rod Pump:

1. Before lowering the sucker rod pump into the well, be sure to check the pump's factory label, markings, and certification to confirm that it is the pump required for the well.

2. Before lowering the sucker rod pump into the well, perform a final inspection to ensure that all protective caps, pipe plugs, or protective caps have been removed and to determine the proper orientation of the pump.

3. Carefully check the plunger's flexibility within the pump barrel and keep both the plunger and the pump barrel lubricated and clean.

4. Inspect all threaded connections for tightness, damage, looseness, or rust.

5. Exercise caution when lowering the pump into the well. When the plunger enters the pump barrel assembly, turn the sucker rod clockwise 2-3 turns to facilitate entry. Increase the stroke distance based on the depth of the well to achieve normal pumping.

IV. Precautions

1. When lifting and unloading the inclined well sucker rod pump, lift slowly and gently, and hoist it steadily. Do not drop, bump, or throw it. When loading and unloading a pump longer than 4.8m (16in), be careful to avoid bending or deformation that may affect the pump's use.

2. The inclined well sucker rod pump should be placed in a dry, ventilated, and clean warehouse. It is prohibited to place it outdoors for a long time. In the warehouse, place the pump flat on a dedicated pump stand with at least two supports. For pumps with a barrel length greater than 4.8m (16in), at least three supports should be placed to prevent the pump from deforming.

3. Before using the pump, all openings of the pump should be packaged or other protective measures should be taken to prevent foreign matter from entering the pump.

4. Before lowering the pump into the well, the threaded connections of each assembly should be inspected for looseness, damage, or rust. The rod should be able to move back and forth freely and rotate freely in the pump barrel without obstruction. 5. For oil well pumps that have passed inspection, disassembly of parts is prohibited unless absolutely necessary.

V. Delivery Status:

1. A "Product Certificate" is included with the pump upon delivery.

2. Fit clearances are determined based on user specifications.

For more detailed information, please click the link to jump to the product page! Inclined Well Sucker Rod Pump