What is Gas Lock?

Some oil wells contain a high concentration of gas, which can enter the pump barrel through the fixed valve. If not promptly vented, the gas will gradually fill the space below the plunger in the pump barrel. As the plunger descends, the liquid in the tubing string acts on the traveling valve, exerting significant pressure. This prevents the traveling valve from opening, compressing the gas in the pump barrel below the plunger and preventing the flow of liquid above the plunger. As the plunger ascends, the compressed gas expands, exerting pressure on the fixed valve, preventing it from opening and preventing the pump from drawing liquid. This repetitive cycle of gas compression and expansion without any discharge is called gas lock.

Solutions for Gas Lock:

If gas lock has already occurred, the following measures can be taken:

Gas lock can be resolved by installing an anti gas sucker rod pump, venting the pump, or reducing the pump speed appropriately. The anti gas sucker rod pump utilizes two pump barrel sections, upper and lower, and an intermediate venting device to store and discharge gas from the tubing during the plunger stroke. This pushes the gas-liquid mixture out of the surface, effectively eliminating gas lock and restoring normal pumping.

Gas lock prevention measures:

To prevent gas lock, the following measures can be taken.

Before gas lock occurs, preventative measures can be taken by selecting an anti gas sucker rod pump suitable for gas-bearing wells, monitoring the gas-liquid ratio in the well, and maintaining the pump barrel and valves. Proper downhole procedures are also crucial, including connecting the upper coupling of the pump barrel assembly to the tubing and lowering it into the wellbore along with the tubing. This ensures that the plunger is lowered smoothly into the pump barrel along with the sucker rod.

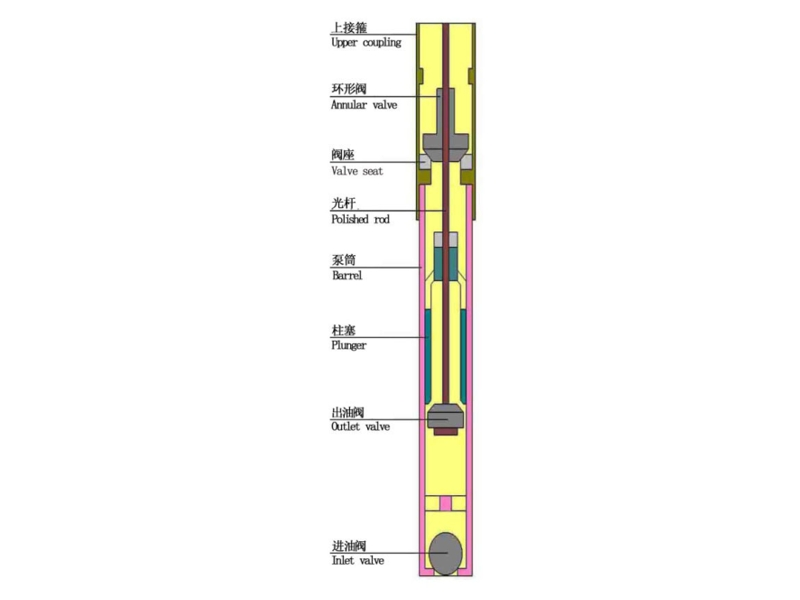

Our company's anti gas sucker rod pump effectively prevents gas lock. The detailed structure and operating principle are summarized below:

The pump barrel of the anti gas sucker rod pump consists of two barrels, upper and lower, with a venting device installed between the two barrels. When the plunger strokes upward to the upper pump barrel, gas is stored in the aerator. When the plunger strokes downward to the lower pump barrel, the gas in the aerator is discharged through the upper pump barrel into the tubing. When the plunger strokes upward again, it pushes both gas and liquid out to the surface. This increases the pump's liquid fill level, eliminates gas locks, and improves pumping efficiency. This pump is suitable for wells with high gas content.

Due to the unique structure of the anti gas sucker rod pump, the pump barrels consist of two separate, upper and lower barrels, with a discontinuous center. A aerator is installed between the two barrels. A slight clicking sound is heard when the plunger passes through the aerator, which is normal and does not affect operation.

The downhole procedure is the same as for a conventional pump: connect the upper coupling of the pump barrel assembly to the tubing and lower it into the wellbore along with the tubing. The plunger is mounted on the lower end of the sucker rod and lowered along with the rod through the tubing into the pump barrel. For the specific procedures for downhole operations, you can visit the article "Safety Tips for Sucker Rod Pumps from Storage to Downhole", which explains the pumping process in detail.