In the field of oil extraction, manual lifting methods are essential. Among them, rod pumps are a common and efficient way to pump oil.This article will discuss in depth the principle, performance analysis and how to choose a suitable pumping device of the rod pump pumping system.

1. Introduction to rod pump pumping:

Rod pump pumping, also known as “beam pumping”, provides mechanical energy for lifting crude oil from the bottom of the tank to the ground. This method has the characteristics of high efficiency, simplicity and easy operation by on-site personnel. It can pump oil wells to extremely low pressures, thereby maximizing crude oil production. In addition, it is suitable for small boreholes, multi-layer completions, and the extraction of high-temperature and high-viscosity crude oil. At the same time, the system can also be transferred to other wells at a lower cost.

However, beam pumping also has some disadvantages. For example, excessive friction will be generated in bending or oblique merging, it is sensitive to solids, it is less efficient in gas-containing oil merging, the carrying capacity of the dry sucker rod is limited, the mining depth is limited, and the equipment is relatively large in offshore operations. However, there are also some development trends in beam pumping, including improved evacuation controllers, better gas separation technology, pumps for processing gas, and the use of ground and parallel bottom diagrams for improvement.

2. Composition of pumping system:

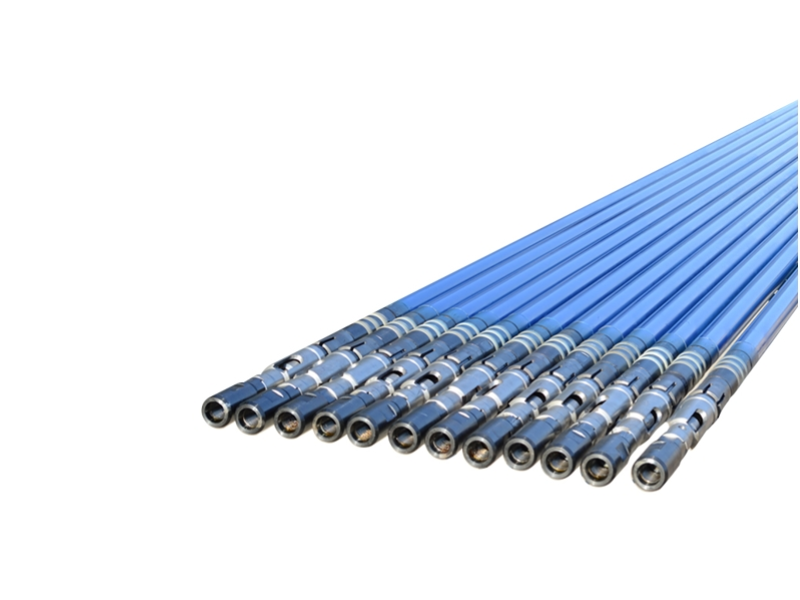

The rod pump pumping system consists of an oil pumping device on the ground and a plunger pump immersed in the production fluid in the well.The power source can be an electric motor or an internal combustion engine. The modern method is to equip each well with a separate electric motor or engine. Among them, electric motors are more popular because they are easy to control automatically.

Power is transmitted to the input shaft of the gear reducer through the V-belt drive, and the output shaft of the gear reducer drives the crank arm at a lower speed (about 4-40 rpm, depending on the characteristics of the oil well and the nature of the fluid). The rotational movement of the crank arm is converted into reciprocating movement through the connecting rod and the travel beam. The donkey head and suspension cable device ensure that the upward tension of the sucker rod column is always vertical, thereby avoiding unnecessary wear and tear on the seal.

3.Detailed working principle:

3.1 The working process of the plunger pump:

The plunger pump is one of the core components of the entire system. The working principle of the plunger pump is as follows: When the crank arm rotates, the rotational movement is converted into linear reciprocating movement through the connecting rod and the travel beam. The sucker rod column moves up and down with this reciprocating movement, driving the plunger of the downhole plunger pump to move up and down. During the upstream process of the plunger, the underground liquid is sucked into the plunger pump chamber, and when the plunger is downstream, the liquid is compressed and discharged through a check valve to the ground piping system. This reciprocating movement allows the liquid to be continuously drawn out of the bottom of the well and finally reach the ground storage facility.

3.2 Power transmission mechanism:

The power transmission mechanism is the key to ensure the stable operation of the entire system.Under normal circumstances, the power provided by the electric motor or internal combustion engine is transmitted to the gear reducer through the V-belt drive.The role of the gear reducer is to reduce the speed and increase the torque, so that the crank arm can operate smoothly at a lower speed.The rotational movement of the crank arm is transmitted to the pumping rod column through the connecting rod and the travel beam, which in turn drives the downhole plunger pump to work.In this process, the coordination and cooperation between each component is essential, and problems in any link may lead to the failure of the entire system.

4. Performance and application considerations:

In practical applications, the efficiency of the rod pump pumping system is affected by a variety of factors.Well depth and well slope angle are the main constraints. They increase the frictional resistance and stress of the sucker rod, especially in large-slope wells. The problem is more prominent.Fluid properties, such as crude oil viscosity, gas content and solid particle content, also significantly affect pump efficiency.For example, high-gas-content oil wells are prone to air locks, which reduce the effective displacement.In addition, the daily maintenance status of the equipment is very important to ensure the long-term stable operation of the system and maintain high efficiency. From an economic point of view, the choice of this system requires a balance between initial equipment investment and long-term operation and maintenance costs. Although the initial investment in motor drive may be slightly higher, its high degree of automation and low operating costs often make it more competitive in long-term operations. Competitive. The potential for yield improvement and adaptability to specific reservoir conditions are also important considerations in the selection.

5. Selection points and development direction:

Choosing the right pumping unit for a particular oil well is a system engineering. We must first fully understand the geological conditions of the oil well, including core parameters such as well depth, well diameter, and reservoir permeability. In addition, we must consider the properties of the mining fluid, such as crude oil viscosity, gas content, moisture content and sand content, and choose materials with corresponding corrosion resistance and wear resistance and structural design equipment accordingly. The operating environment (such as land, sea, and remote areas) also puts forward specific requirements for the size, weight, and wind and wave resistance of the equipment. Choosing reliable suppliers and providing perfect technical support and after-sales service are also indispensable.