During oil production, when reservoir energy is insufficient to support natural crude oil flow, artificial lift systems become essential. Among these, RHA insert rod pumps are widely used worldwide. This article will explain the differences between different RHA insert rod pump models, including their structural components, operating principles, typical applications, technical differences compared to other pump types, and installation methods.

Table of Contents:

What is an RHA insert rod pump

RHA insert rod pump model description

What are the differences between different insert rod pump models

Structural components

Operating principles

Advantages and applicable scenarios

Differences between RHA insert rod pumps and other artificial lift methods

RHA insert rod pump installation methods

What is an RHA insert rod pump?

The RHA insert rod pump is a type of API standard rod pump. Its thick-walled barrel is less sensitive to pressure, allowing it to be lowered to slightly greater depths than similar thin-walled RWA API insert rod pumps. Seat ring options include mechanical (RHAM) or cup (RHAC) for high temperatures, as well as a mechanical type for simplified well maintenance. Mechanical hold-down devices require no maintenance unless significantly damaged, while cup-type hold-down devices should be replaced each time the pump is disassembled. Both types of hold-down devices follow the same setting procedure: the weight of the sucker rod is applied to the pump, which is then lifted upward to disassemble.

The RHA insert rod pump's most distinctive feature is that the pump body is secured to the tubing via a seating assembly. Unlike traditional tubing pumps, it can be installed and serviced without removing the entire tubing, reducing well downtime. This design makes the RHA insert rod pump particularly suitable for wells requiring frequent maintenance or inspections.

RHA insert rod pump model description:

R → rod pump.

H → thick-walled barrel, suitable for highly abrasive and high-pressure well conditions.

A → top anchor point, indicating the pump is secured to the tubing via the top anchor point.

Thus, the RHA is an insert rod pump for oil wells, consisting of a fixed barrel, a thick-walled pump barrel, and a top anchor.

What are the differences between different insert rod pump models?

In addition to the RHA insert rod pump, Dongsheng also offers other API insert rod pump models:

RHB API insert rod pump

RWA API insert rod pump

RWB API insert rod pump

RWT API insert rod pump

RXB API insert rod pump

1. RHA insert rod pump:

Type: Top Anchor, Bottom Hold-Down Valve.

Features: The pump barrel is installed in the tubing and secured by an upper anchor. The suction valve is located at the bottom of the pump.

Applicable scenarios: Conventional vertical wells and medium-shallow wells, allowing for easy pump inspection.

2. RHB API insert rod pump:

Type: Top Anchor, Top Hold-Down Valve.

Features: The fixed valve is located at the top of the pump barrel, suitable for high fluid levels and insufficient well fluid pressure.

Applicable scenarios: Low fluid level wells and conditions requiring reduced gas lock risk.

3. RWA API insert rod pump:

Type: Bottom Anchor, Bottom Hold-Down Valve

Features: The pump barrel is secured by a lower anchor, providing excellent stability. Applicable Applications: Deep or high-yield wells, to prevent the pump body from loosening during operation.

4. RWB API Insert Pump:

Type: Bottom Anchor, Top Hold-Down Valve.

Features: The fixed valve is located on the top of the pump, and the bottom anchor ensures pump body stability.

Applicable Applications: Wells with high gas-oil ratios and those prone to gas lock.

5. RWT API Insert Pump:

Type: Traveling Valve Top, "Tubing Pump Type" but Insert Design

Features: The pump body is positioned by the pump barrel structure and tubing connectors, requiring no additional anchoring devices.

Applicable Applications: Shallow wells or well testing, allowing for quick maintenance, but limited well conditions.

6. RXB API Insert Pump:

Type: Extra Heavy Duty Insert Pump.

Features: Enhanced materials and seals compared to the RWA/RWB design, resulting in enhanced wear and corrosion resistance. Applications: Highly abrasive (high sand content), highly corrosive (acidic fluid), or deep-well production.

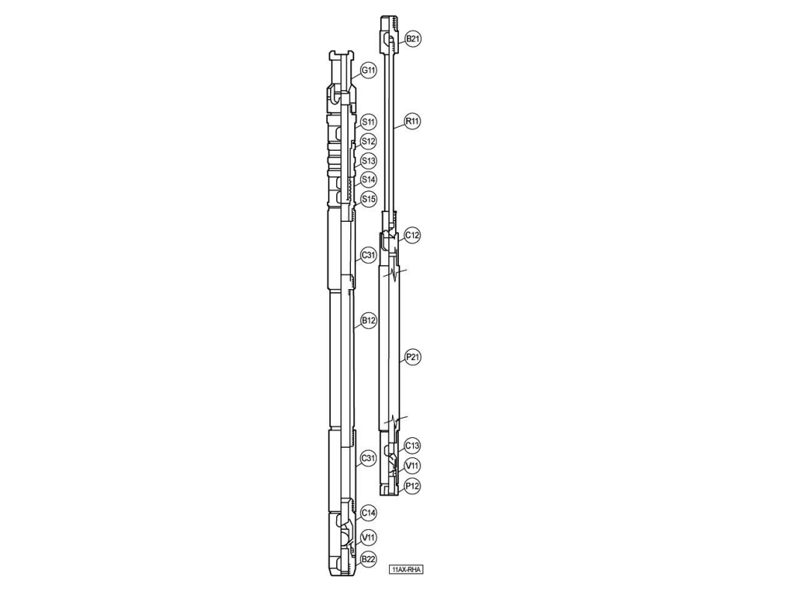

Structural Components:

An RHA insert rod pump system typically includes:

Pump barrel: Made of high-strength alloy steel or nickel-based material, ensuring wear and corrosion resistance;

Plunger: Reciprocates up and down within the pump barrel, lifting liquid through the sealing surface;

Stationary valve (suction valve): Located at the bottom of the pump barrel, it opens during the upstroke, allowing liquid to enter the pump chamber;

Traveling valve (discharge valve): Installed inside the plunger, it opens during the downstroke, forcing liquid into the tubing;

Seating seal: Secures the pump body in the tubing and allows for easy removal via the sucker rod or during workover operations.

Working Principle:

When the pumping unit drives the sucker rod up and down:

During the upstroke, the plunger moves upward, reducing the pressure in the pump barrel, opening the fixed valve and allowing liquid to enter the pump chamber;

During the downstroke, the plunger moves downward, closing the fixed valve and opening the floating valve, forcing liquid into the tubing.

Through this continuous reciprocating cycle, downhole liquid is continuously lifted to the surface.

Advantages and Applications:

The RHA insert rod pump's outstanding advantage lies in its ease of installation and maintenance. Pump inspections can be performed without removing the tubing, saving significant time and cost. Furthermore, the precision design of the valves and sealing components ensures excellent sealing performance and stable drainage efficiency.

The RHA insert rod pump is suitable for applications including:

Old wells entering a period of declining production capacity;

Oil wells with moderate water cut and stable liquid production;

Oil fields requiring frequent pump inspections;

Remote locations, such as coalbed methane and heavy oil wells;

Vertical or low-angle wells with surface installation space.

RHA insert rod pumps differ from other artificial lift methods:

Compared to tubing pumps, RHA insert rod pumps are easier to install and maintain. However, in cases of high well deviation, the sucker rod and tubing are susceptible to eccentric wear. Compared to electric submersible pumps, they offer lower investment costs and simpler construction, but their displacement capacity is limited, making them unsuitable for very high-production wells. Compared to progressive cavity pumps or gas lift systems, RHA insert rod pumps offer more mature maintenance technology and more stable operation, making them particularly suitable for long-term use in medium- and low-production wells.

RHA insert rod pump installation method:

The RHA insert rod pump installation steps typically include:

Installing the surface pumping unit and drive unit;

Logging the sucker rod string;

Securing the RHA insert rod pump into the tubing with the seat seal assembly;

Adjusting the stroke length and pump efficiency to ensure stable operation;

Commencing normal production and integrating the monitoring system for operational data management. For specific RHA insert rod pump downhole steps, please visit the article "Safety Tips for Sucker Rod Pumps from Storage to Downhole"!

We offer not only complete RHA insert rod pumps, but also a comprehensive range of spare parts. Core components such as the valve ball, valve seat, plunger, and pump barrel can be replaced individually, helping customers reduce maintenance costs, minimize downtime, and ensure continuous, stable oil production.