08-13/2025

On the oilfield floor, especially in shallow-to-medium formations, rod pumping has long been one of our engineering team's most commonly used, familiar, and reliable production methods. This isn't to say that other technologies are inferior—submersible electric pumps and progressive cavity pumps have their uses, but when it comes to cost-effectiveness, ease of maintenance, and versatility, rod pumping systems are the preferred choice.

Why do we continue to use rod pumps?

The reason is simple—not all wells are self-flowing, and not all wells warrant the expense of installing electric pumps. Especially when formation pressure is gradually decreasing, or when producing heavy oil, low-yield wells, or cyclic steam injection wells, we need a stable and easy-to-maintain mechanical recovery solution. In these situations, rod pumping is the preferred choice.

Currently, there are two mainstream mechanical recovery methods: gas lift (mostly used in marginal water wells and light oil wells) and deep well pumping. Our rod pumping system is the most mature and widely applicable deep well pumping system.

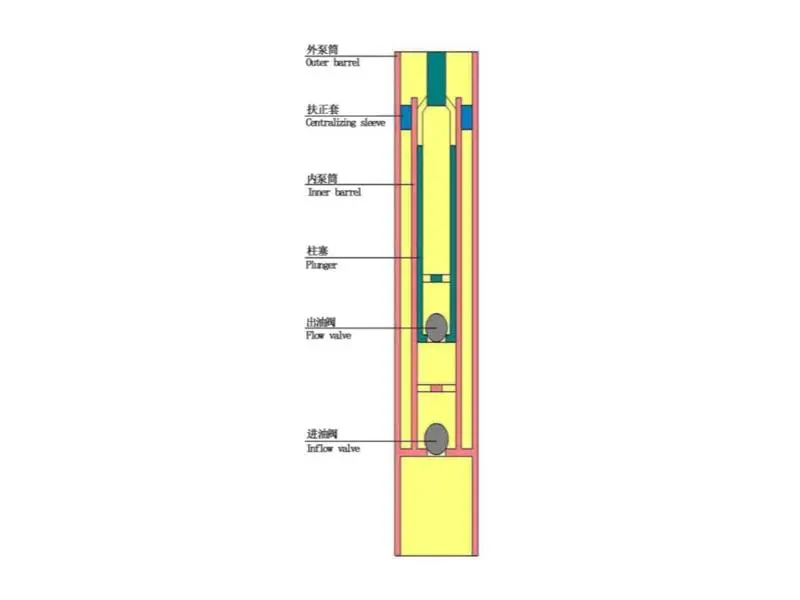

A complete sucker rod pump system consists of three main components:

Surface unit (pump unit): Everyone is familiar with the "kowtow pump," the power source, consisting of a connecting rod and a reduction gearbox.

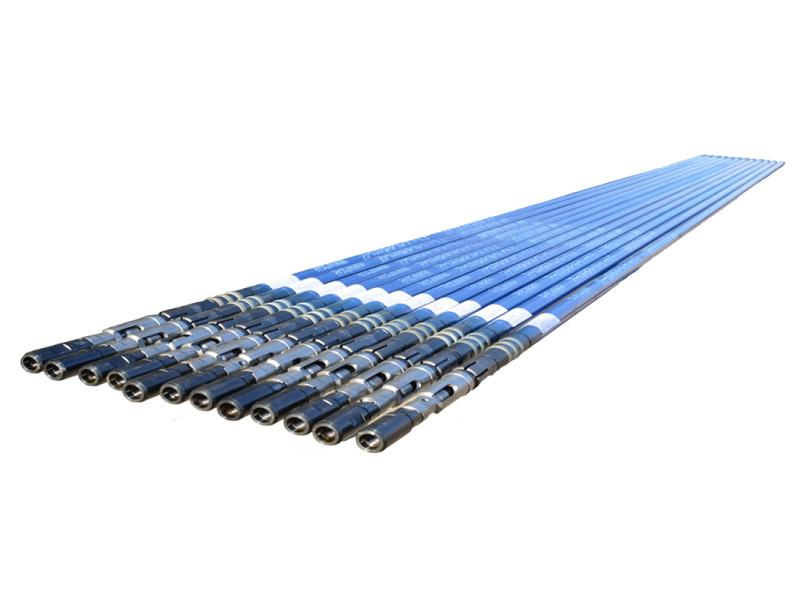

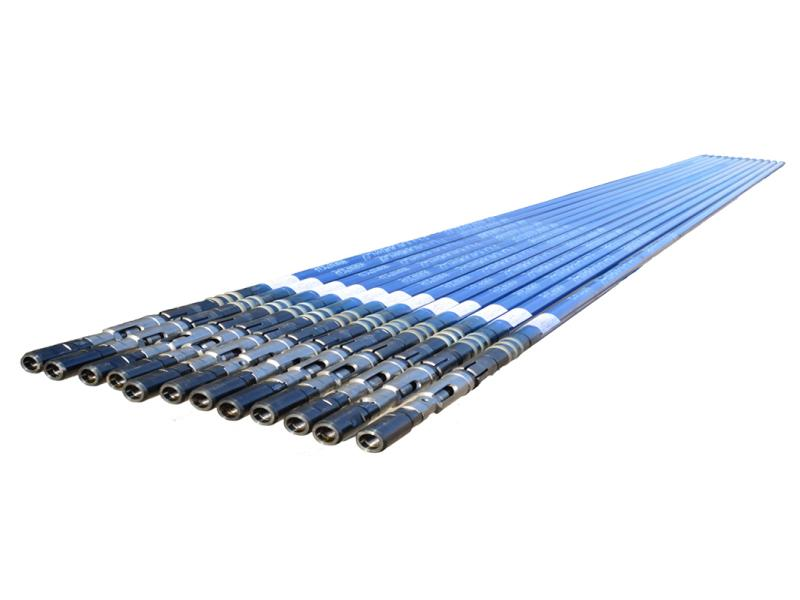

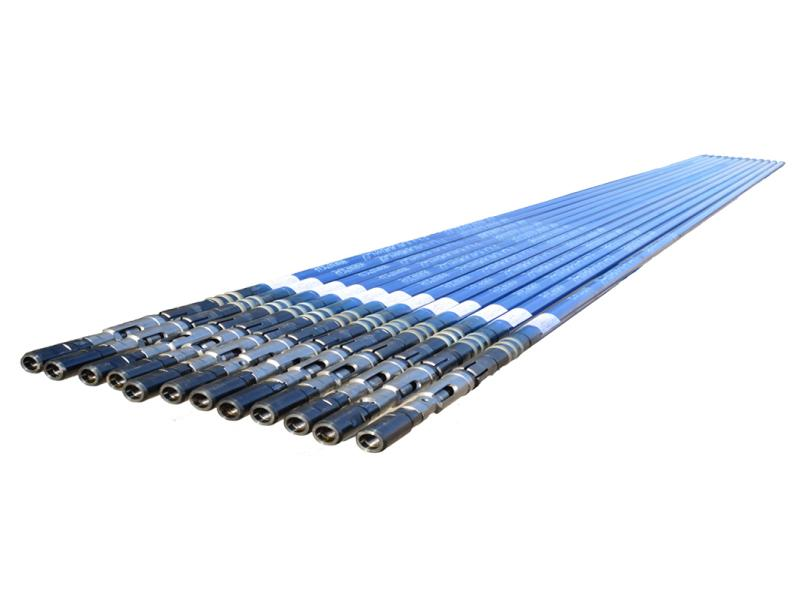

Rod system: Connects the surface to the wellbore, transmitting power to the plunger.

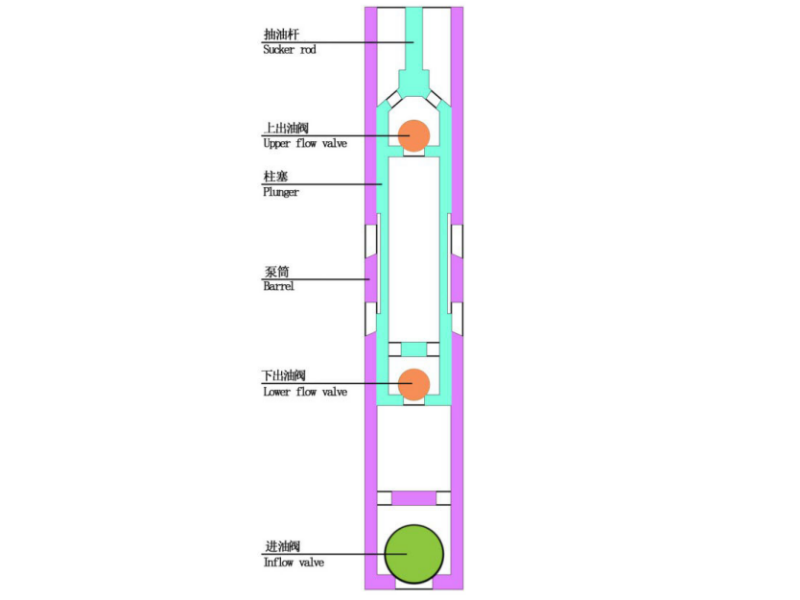

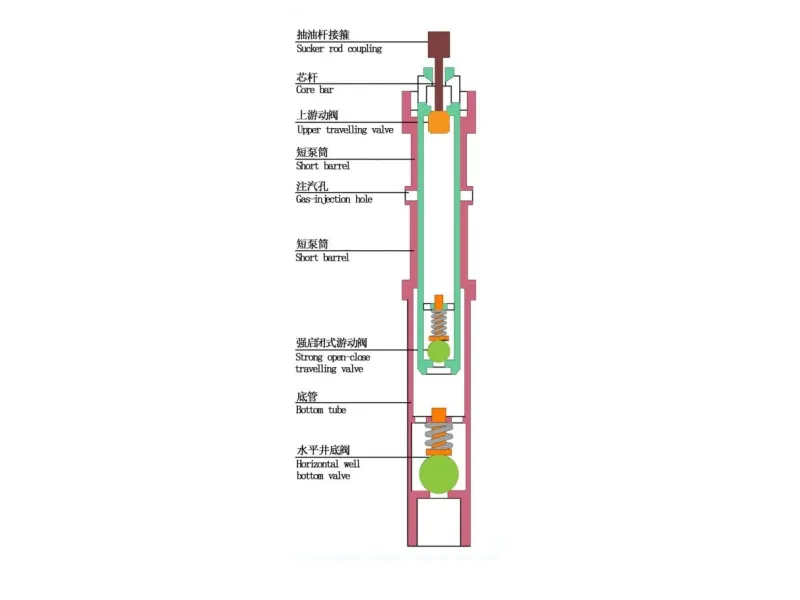

Downhole pump (sucker rod pump): The actual actuator, sucking up fluid and pumping it into the tubing.