I. Definition and Technical Positioning:

A double plunger injection production oil well pump is an artificial lift device utilizing a dual-plunger positive displacement pump structure. It performs both water injection and oil recovery functions, balancing both flooding and extraction. Its double-acting plunger design enables efficient suction and discharge of liquid during both the upper and lower strokes, improving pumping efficiency and system stability.

This structure, similar to a "double-acting double-plunger pump," is widely used in industrial and oilfield injection and production scenarios (Note: it does not simply suction and discharge, but rather the upper and lower plungers circulate separately).

II. Development History and Technological Evolution:

Time period | Key Progress: |

Early 20th century | Single-piston pumps are primarily used, resulting in limited efficiency. |

Mid-to-late 20th century | The integrated injection-production design concept is being promoted, with double-acting pumps gradually being applied to high-pressure systems. |

| 21st century | (SpringerLink) Numerical simulation and optimization algorithms (such as particle swarm optimization) are being introduced to adjust structural parameters and predict performance. |

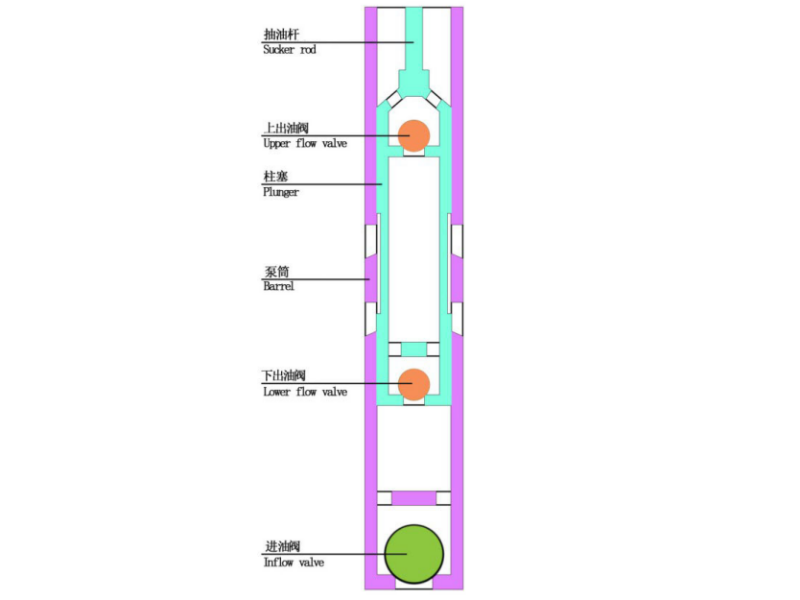

The typical structure consists of the following:

Sucker Rod: Connects the surface power transmission unit to the pump body;

Dual Plunger: Located in the center of the pump barrel, it performs suction and discharge functions at each end;

Piston and Mechanical Switching Valve: Controls the flow rate of fluid in and out of the dual chambers, corresponding to the injection and production process;

Barrel: Precision-engineered internal design, aligning with the high-sealing plunger operation;

Inflow/Lower/Upper Flow Valves: Precisely control flow direction and timing;

Support Housing: Ensures consistent operation and system balance of the double-acting pump.

The structure of the double-plunger injection production oil well pump is consistent with reference models such as those used in studies of linear submersible double-acting pumps and water injection pumps.

1. Double-Stroke Injection and Production Process

Upstroke (Injection or Production): One plunger moves upward to extract or inject fluid;

Downstroke (Opposite Cylinder): The other plunger simultaneously performs reverse flow processing;

The two chambers operate alternately, achieving continuous operation.

This mechanism offers significant advantages in energy savings and pressure stability, and is considered a typical embodiment of a "double-acting pump."

V. Double Plunger Injection Production Oil Well Pump Types and Application Scenarios:

Pump Type | Features | Applications |

Fully double-acting, double-plunger injection pump | Upper and lower plungers for both injection and extraction | Shared wellbore systems for injection and production |

Semi-double-acting design | One end for injection and one end for extraction, simplifying the structure | Small to medium flow injection and production wells |

| Modular intelligent optimization pump type | Adjustable stroke and valve structure parameters | Smart wells requiring online debugging |

VI. Double Plunger Injection Production Oil Well Pump Maintenance Strategy:

Regularly inspect valves, plungers, and seals for wear.

Use an intelligent control system based on simulation prediction to maintain optimal stroke parameters.

Monitor pump vibration, pressure, and flow rate to detect abnormalities promptly.

VII. Troubleshooting Problems and Solutions:

Fault symptoms | Possible causes: | Recommended troubleshooting methods |

Uncoordinated injection and production or flow interruption | Valve sticking, mismatched travel time | Check valve spring and piston wear |

Unstable fluid pressure | Mismatch between structural design parameters and well flow | Re-adjust stroke or pump diameter based on simulation results |

| Decreased pump efficiency | Increased leakage volume due to wear or failure | Disassemble and inspect pump barrel and plunger clearance and seal performance |

VIII. FAQ:

1. How significant is the efficiency difference between a double-plunger injection production oil well pump and a conventional single-plunger pump?

Research shows that a double-acting design can reduce leakage and compression dead zone, improving discharge efficiency by over 20% (based on double-acting theoretical literature).

2. Are there any restrictions on well conditions?

Double-plunger injection production oil well pumps are suitable for integrated injection-production wells, deep wells, high-pressure reservoirs, or reservoirs requiring water injection. The optimized design is adaptable to a variety of well types.

3. Are there any commercial applications?

Relevant equipment has been deployed at customer sites, and the double-acting pump has been proven to be stable in multiple test wells.