Table of contents:

Rodless pump:

Pump selection tips and trivia:

Oil well pumps utilize mechanical intelligence to extract crude oil. Their principles and selection strategies are as follows:

Insert Rod Pump:

A beam pumping unit consists of three components: a surface power source, a four-link transmission, and a downhole pump barrel.

The motor converts rotation into reciprocating motion of the sucker rod via a reduction gear.

A crank-connecting rod mechanism converts circular motion into linear suction.

A plunger pump completes the oil suction and discharge cycle through up and down strokes.

Maintenance Key Points of Insert Rod Pump:

The counterweight design reduces motor load fluctuations. Regularly check the tightness of the connecting bolts.

Heterogeneous pumps achieve 20% energy savings through angle optimization. Keep the crankpin clean.

wells require high-strength sucker rods and optimized stage combinations. Foundation fractures can be repaired with stress welding.

Rodless Pumps: Solutions for Special Conditions:

Two technologies have been developed for unconventional well types:

Electric Submersible Pumps:

Multi-stage centrifugal impellers achieve high-pressure pumping. Anti-cavitation components are required for wells with high gas content.

Ceramic seals address well fluid leakage and are compatible with automatic exhaust devices.

Daily production capacity reaches 1,000 cubic meters, but regular monitoring of wellhead gas content is required.

Hydraulic Piston Pumps:

Hydraulic drive systems are suitable for heavy oil production, with double-acting pump barrel efficiencies exceeding 85%.

Closed-circuit systems address drainage challenges in conditions with a water cut of 92%.

Optimized pipeline layouts are required to avoid power transmission fluctuations.

Selection Guide:

Shallow wells with high production (<300 meters): Tube pumps offer 12% lower energy consumption, but require tubing pull-up for maintenance.

Deep wells with low production (>5,000 meters): Insert rod pump maintenance cycles extend to 18 months, and displacement is only 15 cubic meters per day.

Heavy oil in inclined wells: Hydraulic pumps offer 2.3 times the displacement of rod pumps, increasing pipeline costs by 40%.

Key Data:

Insert rod pumps have a maximum stroke of 3,000 meters (the height of a 300-story building).

Rod string vibration reduces actual stroke by 15%.

Gas anchor devices can separate over 90% of bottomhole gas.

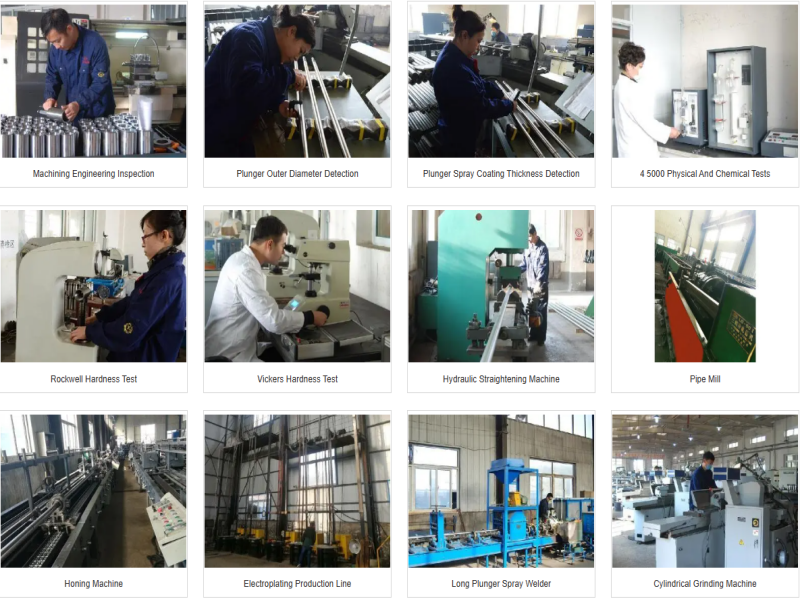

Our company holds API 11AX certification from the American Petroleum Institute. Our product range includes over 100 oil well pump products and accessories, including insert rod pumps, long plunger sand control pumps, oil drains, centralizers, spray-coated metal plungers, straightening pumps, and uniformly ground pumps. We have established a comprehensive testing system, ensuring comprehensive process control and inspection from raw materials, semi-finished products, to finished products.