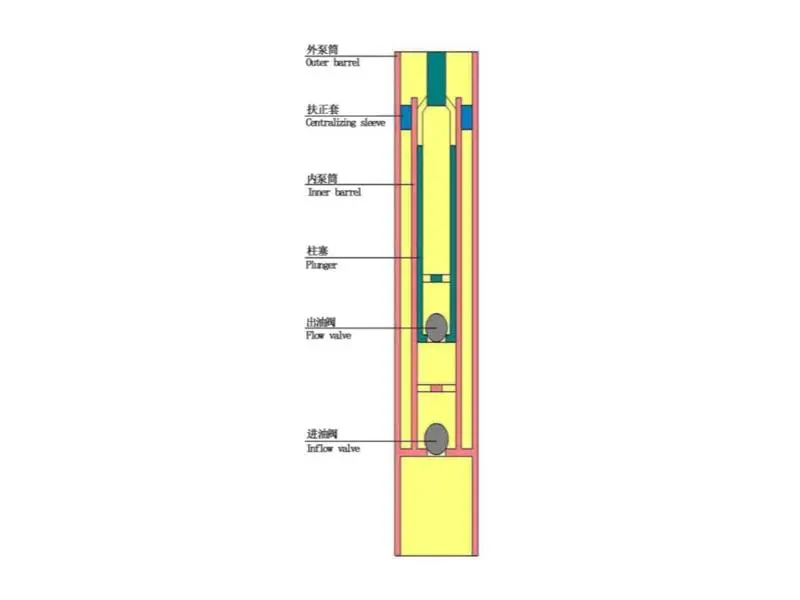

Downhole sucker rod pump adopts an innovative double-layer pump barrel structure. It is designed for deep and thin oil well conditions. It is suitable for oil wells that cannot be produced normally due to insufficient formation fluid supply or low formation pressure in conventional lifting processes. The standard applicable well depth range is 2600 meters to 3500 meters.

Table of contents:

What are the types of downhole sucker rod pumps?

Pump constant corresponding to different pump holes of downhole sucker rod pump

How to use downhole sucker rod pump?

FAQ

How do I buy downhole sucker rod pump from China?

What are the types of downhole sucker rod pumps?

1. The common downhole sucker rod pump with a pump hole size of 28mm is suitable for low-yield wells and heavy oil wells; 32mm pumps are used for low- and medium-yield wells and medium-deep wells; 38mm pumps are used for medium- and high-yield wells and medium- and high-water-bearing wells; 44mm pumps are used for high-yield wells and high-water-bearing wells.

2. There are downhole sucker rod pumps for special working conditions: for heavy oil wells, small pump holes (28mm or 32mm) are recommended; 38mm is preferred for high-sand wells; 44mm is used with caution for deep wells; Sulfur-containing wells need to be equipped with anticorrosive pump cylinders.

Pump constant corresponding to different pump holes of downhole sucker rod pump:

Pump bore (mm ) | Range of stroke (m) | Pump constant of thin oil well sucker oil pump | Size of connecting sucker rod |

Ø28 | 3.0~6.0 | 0.88 | CYG19 |

Ø32 | 1.14 | ||

Ø38 | 1.64 | ||

Ø44 | 2.23 |

How to use downhole sucker rod pump?

1.Fixing the pump cylinder: Slowly lower the pump cylinder assembly through the tubing to the design depth (usually 20-50 meters above the oil layer), and fix it to the casing wall with an anchor or kava.

2.Sucker rod connection: Connect the sucker rod one by one on the ground, and when it is lowered, the plunger is accurately inserted into the inner cavity of the pump cylinder, and the end of the rod is locked with the light rod through a square clip.

3.Wellhead sealing: Install a light rod sealing box, inject high temperature sealing grease and adjust the tightness of the gland to ensure zero leakage at the wellhead.

4.Ground commissioning: Start the pumping unit for no-load test operation, adjust the stroke/stroke to the design parameters, and finally mount the load to officially pump.

Precautions when using downhole sucker rod pump:

It is forbidden to directly use pumps with the largest pump hole size in ultra-deep wells; Small pump holes must be used in heavy oil wells to reduce fluid resistance; anti-wear devices need to be installed in time for high-sand wells.

The process of the pump cylinder going down the well needs to be operated at a uniform speed and smoothly throughout the process: After the pumping rod is connected, the verticality must be calibrated to prevent partial wear; Abnormal fluctuations or sudden drops in efficiency during operation must be stopped immediately.

Corrosion protection should be strengthened regularly in corrosive environments: Complex well types need to be equipped with special anti-partial wear devices; The internal pressure of the pipe column must be completely released before maintenance.

It is forbidden to reuse curved and deformed sucker rods: The power source must be cut off and the equipment locked before operation; Special protective equipment must be strictly worn in hazardous gas environments.

FAQ:

Q: What is the service life of the downhole sucker rod pump?

A: Under normal circumstances, the service life of the downhole sucker rod pump depends on well conditions and maintenance conditions. Under good maintenance, the service life can reach 3-5 years. For complex working conditions such as sand, gas or sulfur, pump body parts may need to be replaced more frequently, and the service life will be shortened accordingly.

Q: What are the common faults of downhole sucker rod pump?

A: Common faults include downhole sucker rod pump stuck, valve group leakage, rod and column fracture, etc.These failures are usually caused by severe shocks, excessive loads, or long periods of unmaintainment. Regular inspection and maintenance can effectively prevent these problems.

How do I buy downhole sucker rod pump from China?

1. Contact us by email, phone or online platform, you can provide us with the required downhole sucker rod pump pump hole size, quantity, application environment and other information.

2. Our professional team will provide product plans and quotations according to your needs, including product details, delivery cycles, etc., and communicate with you for confirmation.

3. After the two parties confirm the plan, they sign a purchase and sales contract to clarify the terms of product information, price, payment method, transportation method, etc.

4. Organize production according to contract requirements to ensure that product quality meets API standards.

5. After the production of the product is completed, strict inspection will be carried out, transportation will be arranged after passing the test, and related documents such as bills of lading, packing slips, and commercial invoices will be provided.

6. After you receive the product, you can contact us at any time if you have any questions, and we will provide a solution in time to protect your rights and interests.

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000. It is a leading manufacturer of oil well pumps, deep well sucker rod pumps and downhole tools for drilling in China. The company has ISO9001 quality management system certification and API 11AX certification, and is committed to providing high-performance oil well pumps, special pumps, and deep well sucker rod pumps for drilling products in oil fields around the world. If you are interested in our downhole sucker rod pump, please feel free to contact us, I believe our products can meet your needs.