On the oilfield floor, especially in shallow-to-medium formations, rod pumping has long been one of our engineering team's most commonly used, familiar, and reliable production methods. This isn't to say that other technologies are inferior—submersible electric pumps and progressive cavity pumps have their uses, but when it comes to cost-effectiveness, ease of maintenance, and versatility, rod pumping systems are the preferred choice.

Why do we continue to use rod pumps?

The reason is simple—not all wells are self-flowing, and not all wells warrant the expense of installing electric pumps. Especially when formation pressure is gradually decreasing, or when producing heavy oil, low-yield wells, or cyclic steam injection wells, we need a stable and easy-to-maintain mechanical recovery solution. In these situations, rod pumping is the preferred choice.

Currently, there are two mainstream mechanical recovery methods: gas lift (mostly used in marginal water wells and light oil wells) and deep well pumping. Our rod pumping system is the most mature and widely applicable deep well pumping system.

A complete sucker rod pump system consists of three main components:

Surface unit (pump unit): Everyone is familiar with the "kowtow pump," the power source, consisting of a connecting rod and a reduction gearbox.

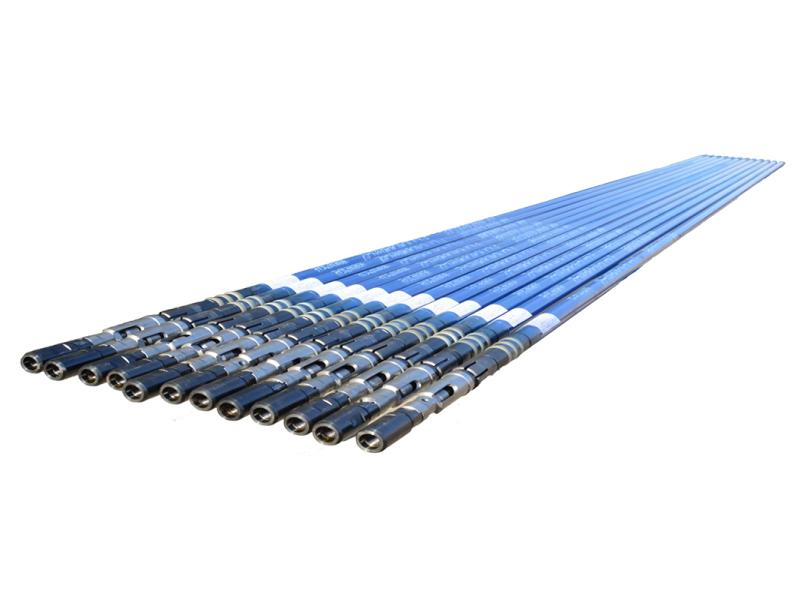

Rod system: Connects the surface to the wellbore, transmitting power to the plunger.

Downhole pump (sucker rod pump): The actual actuator, sucking up fluid and pumping it into the tubing.

Many newcomers ask us: What's the difference between a rod pump and a tube pump? When we install pumps on-site, our primary concerns are: "Is the well deep? Is the production volume high? Is replacing the pump difficult?"

Tube pump: The pump barrel is fixed in the tubing, while the plunger is movable. Its characteristics are simple structure and high flow rate, but the pipeline must be pulled for inspection, making it suitable for shallow and high-yield wells.

Rod pump: The entire pump and rod are lowered into the wellbore together, with the pump stuck in the tubing. This offers the advantage of easy maintenance without having to pull the tubing, but the displacement is relatively small and the structure is slightly more complex.

We currently prefer rod pumps for heavy oil or steam injection thermal recovery projects, especially those with "disposable" pumps. The entire pump is intended to be used until the steam injection cycle is complete, saving time and keeping costs manageable.

When we inspect pump efficiency on-site, we generally look for the following:

Stroke loss: When the rod is subjected to forces downhole, it stretches, and when the tubing is compressed, it shortens. As a result, the plunger moves up and down less than the bare rod. This is more pronounced with deeper wells.

Gas carryover: If there is excessive free gas in the well and the gas-to-liquid ratio at the pump inlet is high, "gas lock" or "opening" can easily occur, causing the valve to fail to open or become sluggish.

Insufficient fluid supply: If the reservoir itself is weak and the fluid level is too low, the pump will pump out air.

Lockout: Wear on the rod pump plunger, bushing, or valve disc, as well as sand or wax blockage, can cause fluid to escape.

How can we improve rod pump efficiency on-site? Here are some practical experiences:

In terms of design parameters, we tend to favor large strokes, low stroke rates, and small pump diameters to minimize gas impact and shock loads.

For heavy oil wells, we instead use a combination of large pump diameter, large strokes, and low stroke rates. High viscosity improves rod pump chamber fluid exchange capacity, while low stroke rates reduce system fatigue.

Appropriately increasing the rod pump's submergence (depth below the liquid surface) ensures more stable suction.

Regularly using air anchors or separators prevents gas from directly entering the pump.

For wells with significant stroke loss, we use tubing anchors to secure the tubing and prevent it from "breathing."

For sand and wax control, we typically add wax scrapers or sand screens to older wells. New wells are increasingly using wear-resistant alloys to extend pump life.

This isn't in conflict with rodless pump systems; it's complementary.

This doesn't mean we only specialize in pushrod pumps. For example, rodless pumps are more suitable for the following scenarios:

Electric submersible pumps (ESPs): High-yield deep wells and high-pressure water injection wells. They offer high power and throughput, but are expensive and difficult to maintain.

Hydraulic piston pumps: Suitable for heavy oil wells and cold production, with recovery systems and high pressure.

Hydraulic jet pumps: Completely free of moving parts, sand-resistant and corrosion-resistant, suitable for wells with extremely high sand content.

Surface-driven progressive cavity pumps: Like a propeller, they are suitable for ultra-heavy oil or polymer flooding projects.

Our daily work in well diagnosis, pump selection, and equipment maintenance relies heavily on understanding and optimizing rod pump systems. While not cutting-edge, rod pumps are the most reliable, cost-effective, and easily implemented solution in many operating conditions.

If you are also involved in artificial lift or field maintenance, we welcome discussions about the application of these technologies in specific scenarios. We firmly believe that technology is demonstrated through practice, not just theory.