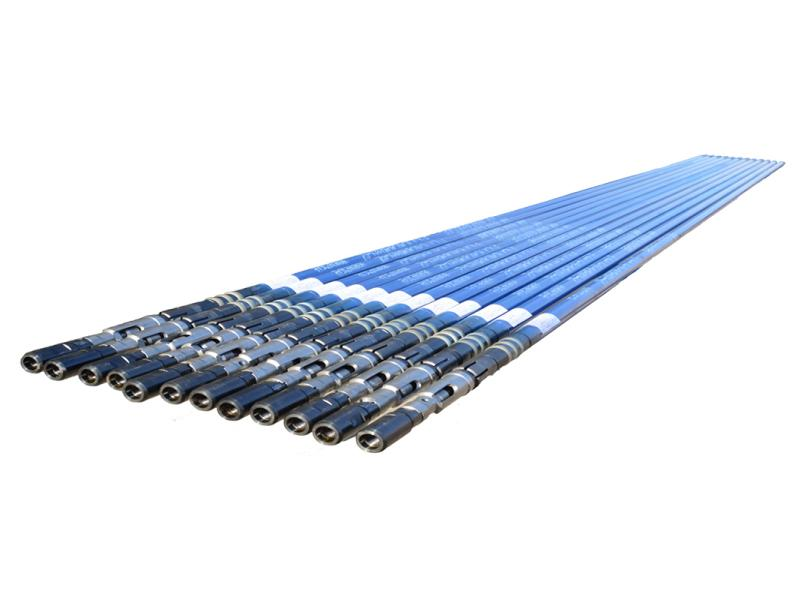

The insert rod pump is a piece of equipment widely used in oil production, featuring a simple structure, easy maintenance, and high reliability. This article will explain the working principle, structural features, operation, maintenance, and troubleshooting of the insert rod pump to help readers better understand and apply this equipment.

I. Working Principle of the Insert Rod Pump:

The insert rod pump primarily consists of a piston, a pump barrel, a check valve, and a spring. The piston reciprocates up and down within the pump barrel, pumping oil from the wellhead to the surface. When the piston moves upward, the pressure within the pump barrel decreases, causing the check valve to open and allow oil to enter the barrel. When the piston moves downward, the pressure within the pump barrel increases, closing the check valve and allowing oil to be discharged through the oil hole in the piston and the drain pipe.

II. Structural Features of the Insert Rod Pump:

1. The piston and pump barrel are made of high-quality steel, offering high wear and corrosion resistance.

2. The check valve is made of stainless steel, providing excellent sealing performance and a long service life. 3. The spring is made of a special material with high elasticity and corrosion resistance.

4. The entire device has a compact structure and is easy to install and maintain.

III. Insert Rod Pump Operation and Maintenance:

1. Before use, check that all components are intact, especially the check valve and spring.

2. During installation, ensure that the pump barrel is aligned with the wellhead and securely fastened with bolts to ensure a good seal.

3. Regularly check the operation of the device during use. If any abnormality is detected, immediately shut down the device for inspection.

4. Regularly clean the pump barrel and piston to remove accumulated impurities and dirt to ensure proper operation.

5. When the device is not in use for an extended period, remove the piston, clean it, apply anti-rust oil, and store it in a dry and ventilated area.

IV. Insert Rod Pump Troubleshooting:

1. Check valve leakage: This may be caused by a worn check valve, a broken spring, or other issues. In this case, replace the check valve or spring. 2. Pump barrel leakage: This may be caused by barrel wear, damaged seals, or other factors. In this case, the barrel or seals should be replaced.

3. Piston seizure: This may be caused by piston wear, dirt accumulation, or other factors. In this case, the piston should be cleaned or replaced.

4. Insufficient oil pumping: This may be caused by aging equipment or complex downhole conditions. In this case, the equipment should be inspected and, if necessary, parts replaced or alternative oil recovery methods adopted.

In short, the insert rod pump, as an important piece of oil production equipment, has the advantages of simple structure, easy maintenance, and high reliability, making it widely used. This article introduces the operating principle, structural features, operation, maintenance, and troubleshooting of the insert rod pump, hoping to be helpful. If you encounter any problems during use, please refer to this article for troubleshooting.