Triple-Acting Sucker Rod Pumps:

Our company's Triple-Acting Sucker Rod Pumps feature an upper pump barrel installed within an outer tube. The lower portion of the upper pump barrel is connected to the lower pump barrel, with a sealing device installed between the upper and lower pump barrels. An intermediate oil delivery valve is installed between the lower portion of the outer tube and the upper portion of the lower pump barrel. The lower pump barrel has an intermediate connecting hole in its upper portion, and an intermediate oil inlet valve is installed between the lower portion of the outer tube and the upper portion of the lower pump barrel. The intermediate oil delivery valve is located above the connecting hole, and the intermediate oil inlet valve is located below the connecting hole. The lower portion of the lower pump barrel of the Triple-Acting Sucker Rod Pump is equipped with a lower oil inlet valve. The sucker rod, upper oil delivery valve, upper plunger, hollow connecting rod, and lower plunger are connected in sequence. An upper cavity is located between the upper plunger and the sealing device. An upper connecting hole is located on the upper portion of the hollow connecting rod, connecting the upper cavity to the hollow connecting rod. A cavity is located between the sealing device and the lower plunger, which communicates with the lower portion of the intermediate oil delivery valve through the connecting hole. A triple-acting sucker rod pump has a lower chamber between the lower plunger and the lower inlet valve. Its large displacement increases well production. Its compact size makes it suitable for use in standard casing and has a wide range of applications.

Structural Features Analysis:

Multi-Plunger Design:

The triple-acting sucker rod pump integrates three plungers and corresponding pump chambers, effectively distributing mechanical loads and reducing pressure fluctuations associated with a single plunger, ensuring continuous and smooth fluid delivery.

Strong Sealing Design:

A high-precision clearance design between the plunger and the pump barrel ensures a continuous seal, reduces the entry of solid particles such as sand into the gap, and reduces the risk of wear and clogging.

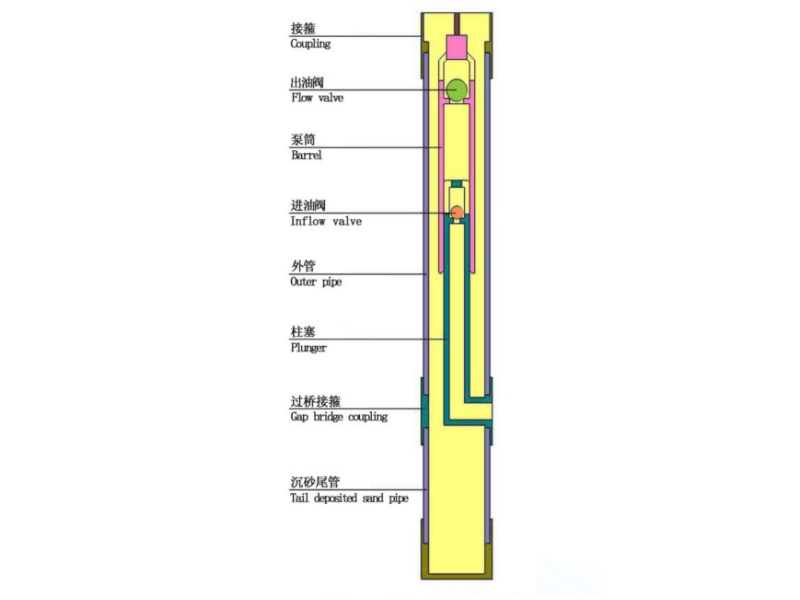

Next, we will take a deeper look at more details of the movable barrel sand control oil well pump.

1. Detailed explanation of the working principle of the movable barrel sand control oil well pump: During the working process of the movable barrel sand control oil well pump, during the upstroke, the sucker rod will move the movable barrel sand control oil well pump upward, causing the oil outlet valve to close. As the space in the pump barrel cavity gradually increases, the pressure begins to drop. At this time, the liquid in the well will push the oil inlet valve open and smoothly enter the pump cavity. During the downstroke, the pump barrel moves downward, and the pressure in the pump increases accordingly. The oil outlet valve opens under the action of pressure, while the oil inlet valve closes. In this way, the liquid in the pump is smoothly discharged and flows into the oil pipe.

2. Analysis of structural features: In the movable barrel sand control oil well pump, the pump barrel is responsible for the up and down reciprocating motion, and the plunger is stably fixed to the pipe string through an extension tube. (2) The oil outlet valve is always above the pump barrel to ensure that sand burial and sand jamming can be effectively prevented when pumping is stopped. At the same time, the sand deposited in the annular space between the pump barrel and the outer pipe will not be accidentally pumped out again. (3) Since the plunger extension tube belongs to the slender rod category, its stability is relatively poor. Therefore, this type of pump is not suitable for long-stroke pumping operations and is not suitable for use in heavy oil wells. (4) Since the movement space of the pump barrel in the oil pipe is limited, the displacement of this pump is relatively small. In addition, the size of the oil inlet valve is smaller than the oil outlet valve, which will produce a certain impedance to the liquid flow.

Bridge pump:

1. Detailed explanation of the working principle: In the working process of the bridge pump, the upward and downward movement of the plunger plays a key role. When the plunger moves upward, the fixed valve opens and the floating valve closes at the same time, so that the oil is lifted and injected into the lower chamber of the pump barrel. As the plunger moves further upward, after reaching the set stroke, the upward stroke ends and the pump chamber is filled with oil. When the plunger moves downward, the fixed valve closes and the floating valve opens, and the oil returns to the upper chamber of the pump barrel along the upward path of the plunger and is discharged through the oil pipe. In this way, the downward stroke also ends. 2. Structural Features:

The fixed valve at the bottom of the pump is designed as an annular space. This ingenious structure provides ample space for debris to fall through. This design effectively prevents the inlet from being clogged by sand and debris that could fall directly.

(2) The unique fixed valve inlet and outlet design effectively prevents sand and debris from reciprocating within the pump due to the reciprocating motion of the plunger, which could cause blockage of the pump's inlet and outlet. This design is particularly suitable for double-acting oil well pumps.

That's all for this article! We hope you find it helpful.

The next article will explain the classification of commonly used oil well pumps internationally. Stay tuned!