I. Injection and Production Pump Overview:

The injection and production pump is a simplified injection pump designed for steam flooding/huff-and-puff operations in high-temperature heavy oil wells. Its core feature is dual-use injection and production: simple and reliable conversion between injection and production.

The injection and production pump utilizes a large-diameter, long-stroke pump barrel and plunger, effectively increasing fluid production. A dedicated disconnector for large pumps is used to disconnect the plunger from the sucker rod. The upper outlet valve and lower portion of the plunger are machined with sharp-angle scraping edges. In annular thermal recovery wells, the reciprocating motion of the plunger continuously removes scale and sand from the inner wall of the pump barrel, reducing and preventing sand blockage. The injection and production pump is suitable for pumping heavy and extra-heavy oil under challenging conditions such as high temperatures and sand content. The heavy oil pump successfully addresses the challenges of extra-heavy oil recovery.

II. Technological Evolution and Application Development of Injection and Production Pumps:

Phases | Core Changes |

Early Stage (1960s–1980s) |

|

Optimization Stage (1990s–early 2000s) |

|

| Current |

|

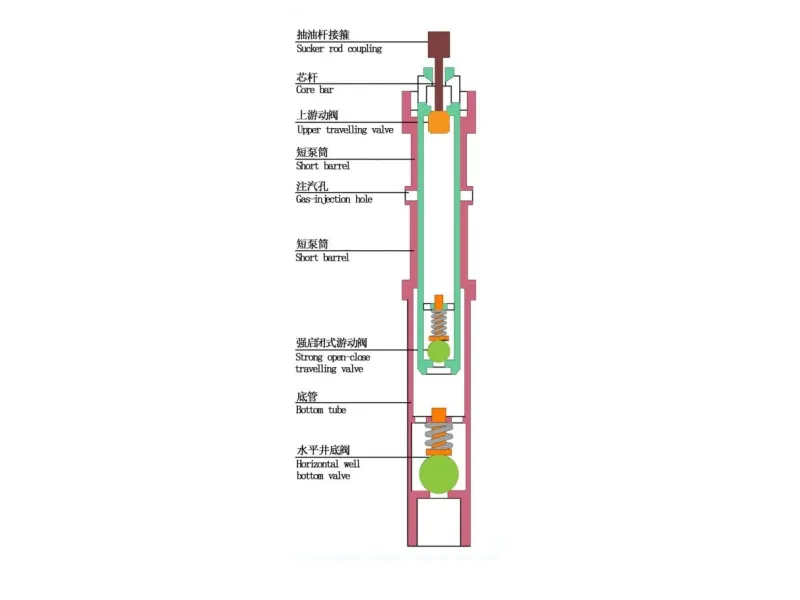

III. Structural Analysis of Injection and Production Pumps:

This pump is designed to last the entire steam injection cycle without requiring repairs after being run into the well. Its compact structure avoids frequent pumping operations under high temperatures.

It is connected to the surface pumping head via a sucker rod, compatible with traditional rod-type pumping equipment and offering excellent wellsite versatility.

The structural materials can withstand high temperatures and high pressures in corrosive environments of 200-300°C, meeting the stringent requirements of steam-driven oil production.

IV. Injection and Production Pump Types and Application Scenarios:

Pump Type Features Recommended Operating Conditions

Standard Disposable Injection Pump: Universal structure, suitable for conventional wells <1000m deep, heavy oil huff-and-puff wells, and intermittent steam injection wells.

High-Pressure, Temperature-Resistant Type: Pump body constructed of nickel-based or chromium-molybdenum alloy, temperature resistant >320°C. Suitable for high-pressure environments such as deep heavy oil wells and edgewater wells.

Customized Port Type: Customizable interfaces based on on-site steam string configuration. Suitable for retrofitting existing wells with high compatibility requirements.

V. Typical Failures and Solutions for Injection and Production Pumps:

1. Severe Backpressure After Steam Injection

Possible Cause: The check mechanism within the pump body is not fully closed or is malfunctioning, causing high-pressure steam to flow back to the surface after the pump is shut down during steam injection. Recommendations:

Use highly elastic nickel-based check discs with a thickness of ≥3mm instead of conventional stainless steel springs to improve closing force at high temperatures.

Inspect the contact surface between the check seat and the valve disc inside the pump for erosion or carbon buildup. If so, replace the entire check assembly.

For wells with frequent backpressure, a double check disc design is recommended to increase sealing redundancy.

2. Low steam injection efficiency and insufficient thermal recovery penetration

Possible cause: Scale, wax, and carbon deposits in the flow restriction channel or nozzle area, resulting in poor steam flow.

Solution:

In the initial design phase, select a straight-through steam injection orifice with a diameter of ≥10mm to prevent particle accumulation from affecting flow after long-term operation.

If steam injection volume decreases, flush the surface and pump steam injection channels using a combination of high-pressure water and oil-displacement agent.

If you have specific steam injection parameters and well conditions, we can provide injection and production pump structural diagrams, supporting selection recommendations, and user manuals.