09-11/2025

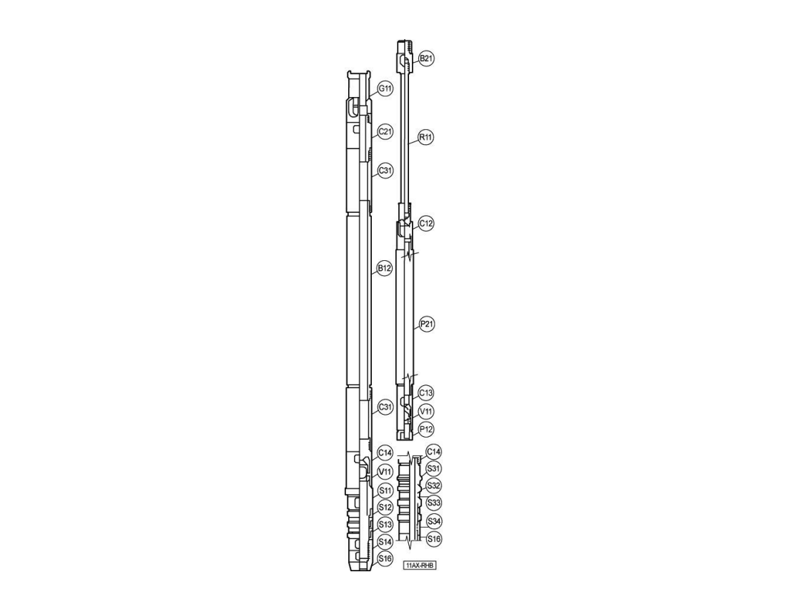

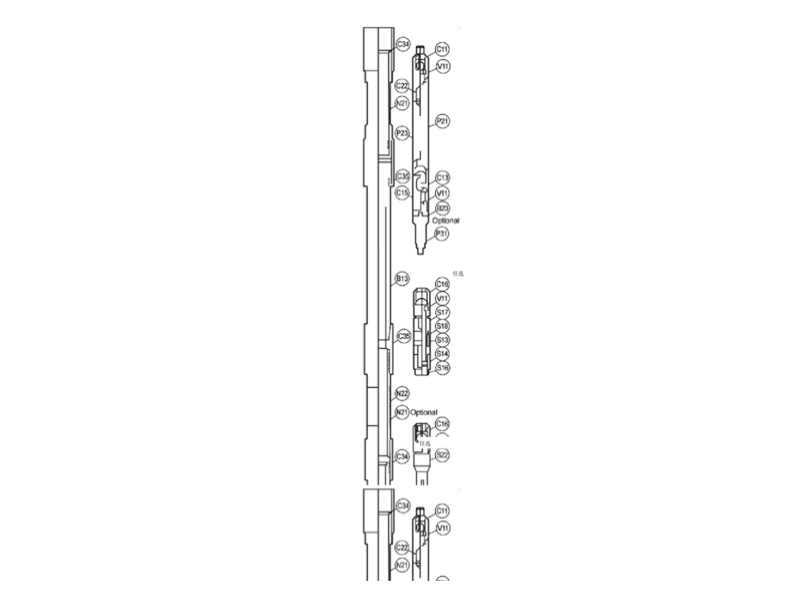

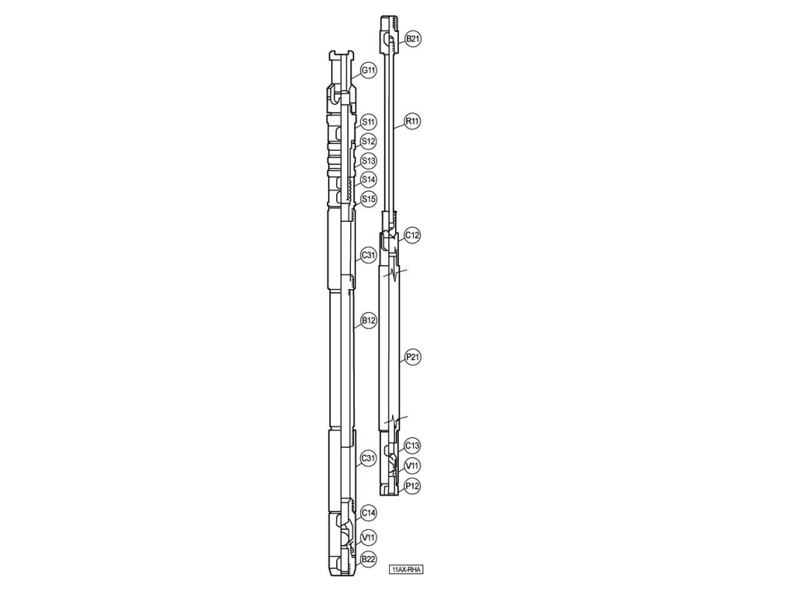

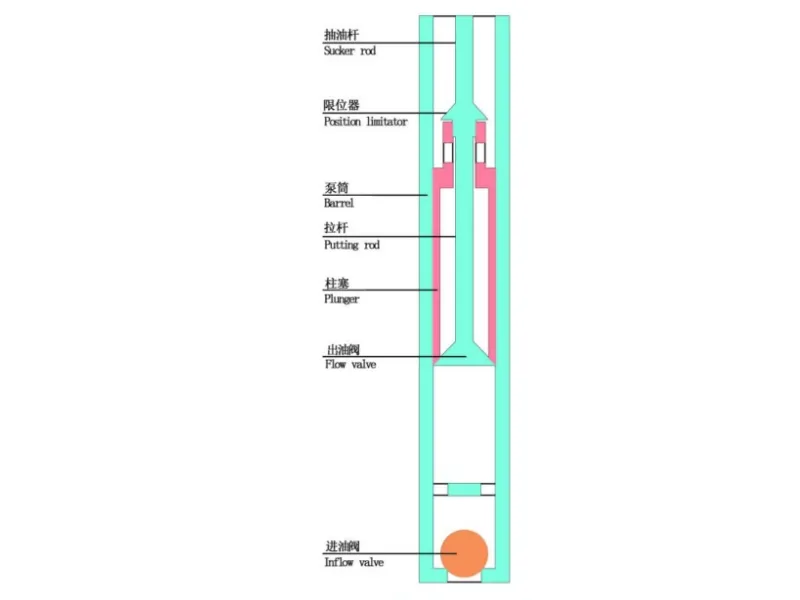

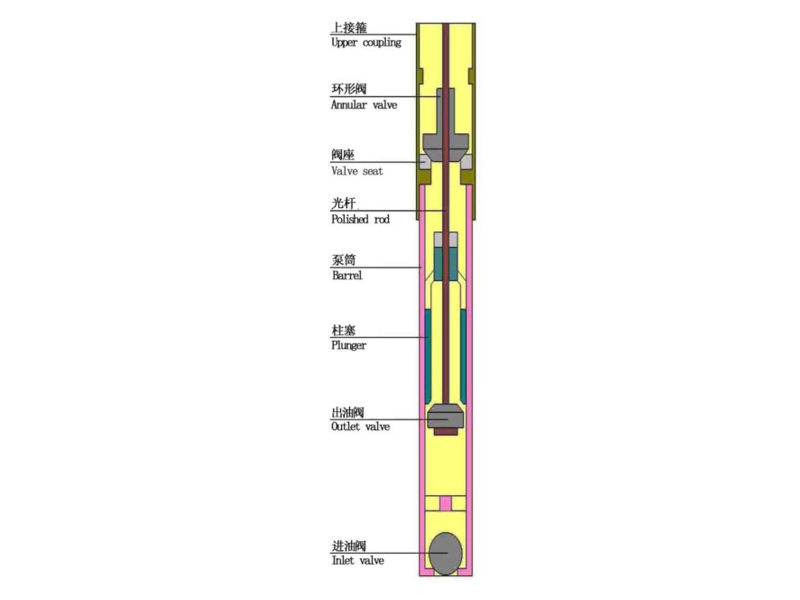

Maintaining efficient and stable crude oil production in environments with sand content, low liquid levels, deviated wells, and intermittent production has become a focus of industry attention. As a core piece of equipment in traditional mechanical oil production, the insert rod pump exhibits wide adaptability due to its diverse structural configurations. Among them, the top-fixed insert rod pump with a fixed barrel, the bottom-fixed insert rod pump with a fixed barrel, and the bottom-fixed insert rod pump with a moving barrel each play an important role in different operating conditions due to their unique structural advantages.