When engineers decide to use gas lifting technology to implement manual lifting, a common question is: Are the sizes of these devices the same? The answer is like the depth of oil wells varies-there is no standard size for gas lifting systems. Its design fully follows the principle of "tailor-made", which is an important embodiment of the flexibility of manual lifting.

For the uninitiated, it can be imagined like this: A gas lift is like “equipping a ventilator” to an oil well.Infants, athletes and the elderly need different amounts of oxygen, and the sizes of ventilators naturally vary. By the same token, the artificial lifting support required for young high-yielding wells is very different from that required for aging low-yielding wells. The engineer will calculate the optimal gas injection volume based on the “physical examination report” of the oil well (pressure test, fluid analysis, etc.), and then push back the size of the equipment-the whole process is the core of the scientific nature of manual lifting.

Modern artificial lifting technology has even developed a "retractable design". In an oilfield in the Tarim Basin, engineers installed an air lift device with an expansion interface in response to the decline in production. The basic module is used in the initial stage, and the booster unit is superimposed in the later stage to avoid equipment waste. This dynamic adjustment ability makes manual lifting an efficient investment choice.

It is worth noting that the size difference is not only reflected in the ground equipment. The diameter of the downhole air lift valve ranges from 1 cm to 5 cm, just like a faucet of different caliber, which controls the accuracy of gas injection. A well may be equipped with 10 air lift valves of different sizes, which together form a complete artificial lift system.

Back to the original question: Is there a uniform size for the gas lift? The answer is no. This diversity is not a defect, but a sign of the maturity of artificial lifting technology. It proves that humans can design the most matching energy solutions for ever-changing geological conditions. When we see flowing gasoline at a gas station, it may be a giant compressor in the desert or a miniature module on an offshore platform behind it-it is these exclusive and customized artificial lifting equipment that silently supports the blood of modern energy.

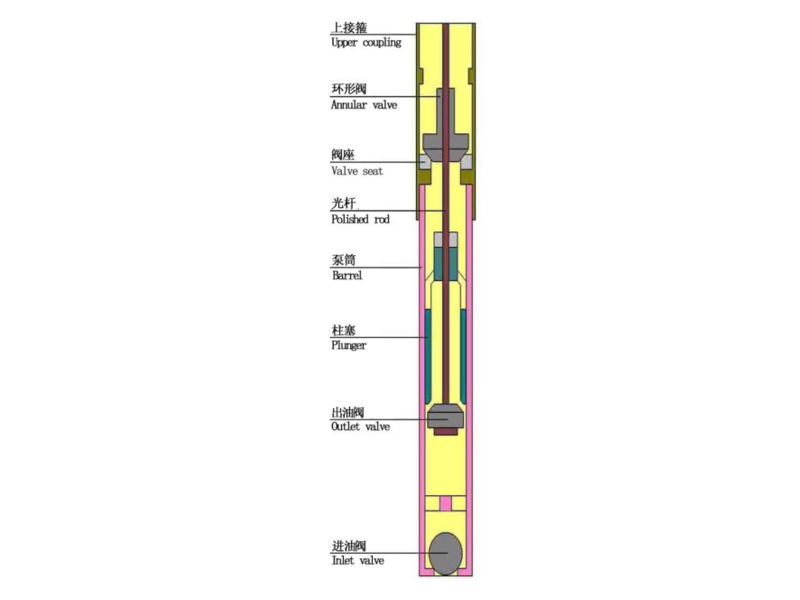

Dongsheng uses high-strength alloy steel and wear-resistant coating technology on key components such as the pump barrel and plunger to improve the wear resistance and corrosion resistance of the parts. This reduces energy loss caused by friction, allowing the pump to maintain high efficiency in high-sand and highly corrosive oil wells. Customers who are interested in purchasing our products are welcome to leave us a message at any time!