08-30/2025

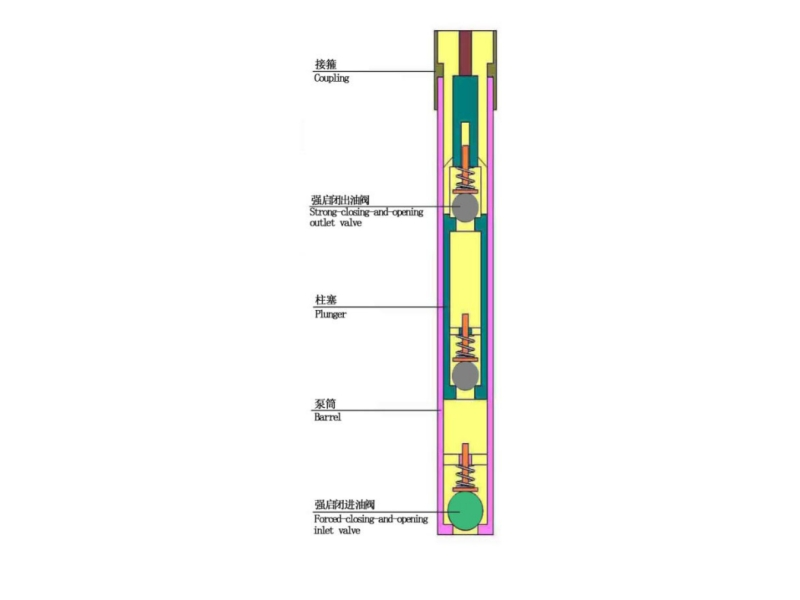

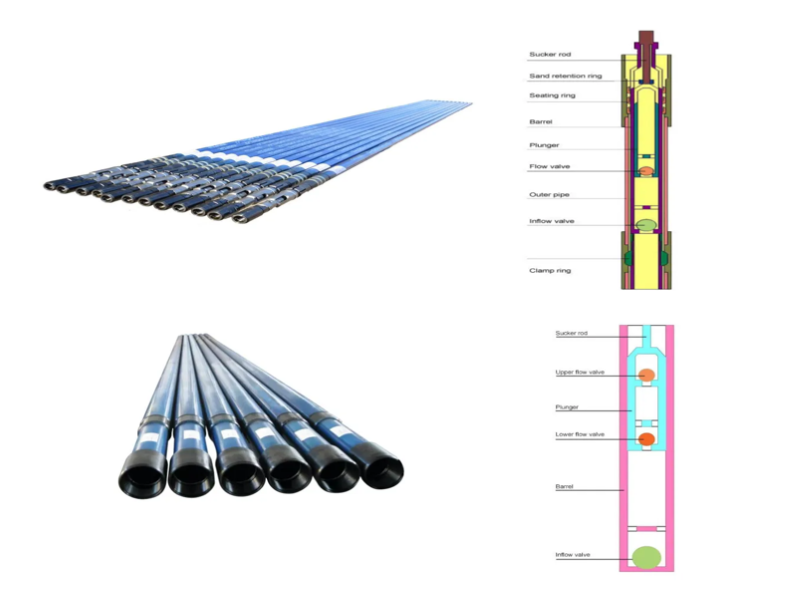

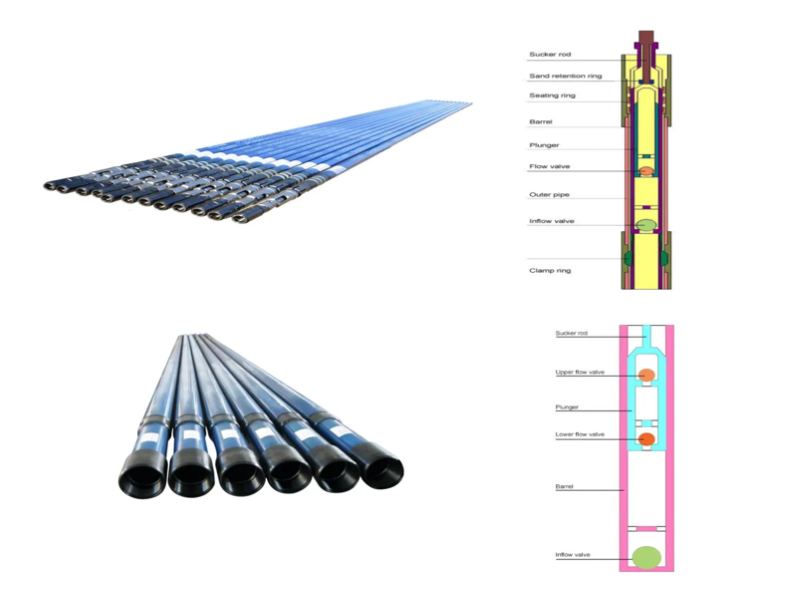

For this reason, "how to efficiently and economically clean oil well pumps" has become a crucial concern for oil production plants, service companies, and even every on-site worker. Drawing on field experience and industry practices, we have compared and summarized the cleaning methods for API rod pumps and API tubing pumps.