Maintaining efficient and stable crude oil production in environments with sand content, low liquid levels, deviated wells, and intermittent production has become a focus of industry attention. As a core piece of equipment in traditional mechanical oil production, the insert rod pump exhibits wide adaptability due to its diverse structural configurations. Among them, the top-fixed insert rod pump with a fixed barrel, the bottom-fixed insert rod pump with a fixed barrel, and the bottom-fixed insert rod pump with a moving barrel each play an important role in different operating conditions due to their unique structural advantages.

Top-fixed insert rod pump with a fixed barrel:

The top-fixed design is the most commonly used insert rod pump. The plunger of this pump is connected to the sucker rod and moves up and down with it. The pump barrel is secured at the top by a fixture. This design offers the following advantages:

1. During operation, the fluid discharged from the guide sleeve can flush sand deposited between the top of the pump barrel and the tubing, preventing sand sticking. Therefore, it is suitable for use in sand-laden wells.

2. The fixed valve is located at the bottom of the pump, making it easily immersed in the well fluid, making it suitable for use in wells with low liquid levels. 3. The top-mounted design allows the pump to hang freely and features self-alignment, making it suitable for use in deviated wells.

4. The pump barrel acts as an air anchor, making it suitable for use in gas-bearing wells. However, since top-mounted pumps are subject to tensile loads caused by internal pressure and the fluid column, and the barrel tends to expand during the upstroke, increasing the plunger clearance, they are not suitable for deep wells.

Insert rod pump with fixed barrel:

The plunger of this pump is connected to the sucker rod and moves up and down with it. The pump barrel is secured at the bottom by a fixture. This design offers the following advantages:

1. The pump barrel is subject only to external pressure, not tensile loads caused by the weight of the fluid column. Therefore, pump clearance changes are minimal, making it ideal for use in deep wells.

2. Compared to other standard pumps, the pump barrel is less susceptible to pressure-induced fracture or bending.

3. Since the pump body can swing about the bottom fixture, it can be used in deviated wells. However, be aware that there is a tendency for friction between the valve stem guide sleeve and the valve stem. If the guide sleeve is made of too hard a material, it will wear the valve stem. However, this type of pump is not suitable for long-stroke applications because its support point is at the bottom. Excessive strokes can cause displacement of the top, increasing wear between the valve stem and the guide sleeve. Furthermore, sand can easily accumulate in the annular space between the pump and the tubing, making it unsuitable for use in sandy wells.

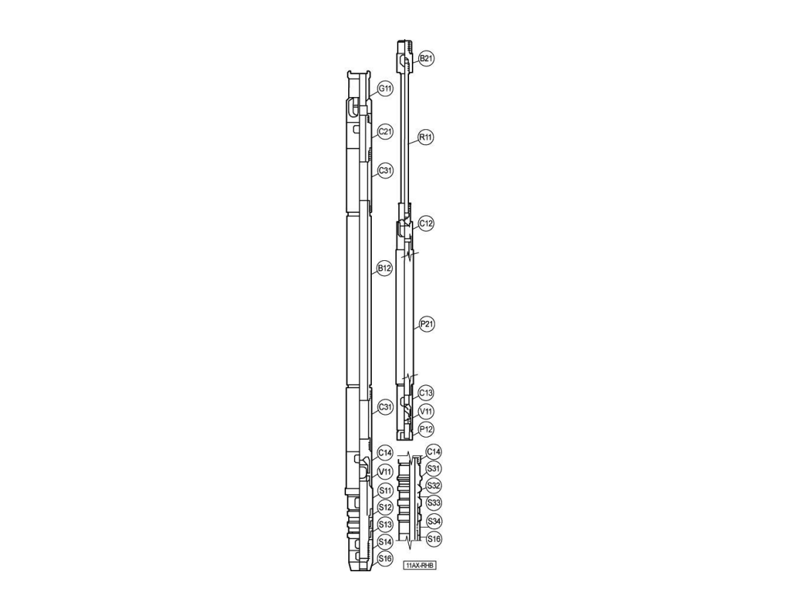

Moving-barrel bottom-fixed insert rod pump:

The pump barrel of this type of pump is connected to the sucker rod and moves up and down with it. The plunger is secured by a mechanical or cup-type bottom fixture. It offers the following advantages:

1. The reciprocating motion of the pump barrel keeps the liquid agitated during operation, preventing sand from settling, making it suitable for sandy wells.

2. When the pump is stopped, the valve ball in the upper valve housing returns, preventing sand from accumulating in the pump, making it suitable for intermittent production operations.

3. Both the fixed and floating valves utilize open housings, which provide a larger flow area than closed housings.

As you can see, insert rod pumps with different mounting methods are suitable for different applications: fixed-tube top-mounted pumps are suitable for sand-laden wells, low-liquid-level wells, and deviated wells; fixed-tube bottom-mounted pumps offer significant advantages in deep well environments; and moving-tube bottom-mounted pumps excel in sand-laden wells and intermittent production. Dongsheng is a leading pump manufacturer in China, dedicated to the design, development, manufacture, and supply of oilfield products such as wellbore pumps, specialized wellbore pumps, and downhole tools. We are a qualified supplier to CNPC, Sinopec, and Weatherford. We are ISO9001 certified and hold API 11AX certification from the American Petroleum Institute. Our product line includes over 100 types of wellbore pumps and accessories, including long-plunger sand control pumps, oil drains, centralizers, spray-coated metal plungers, straightening pumps, and uniformly ground pumps. We have established a comprehensive testing system, ensuring comprehensive process control and inspection from raw materials to semi-finished products to finished products.

Our products are widely used in major domestic oil fields such as Liaohe, Daqing, Changqing, and Shengli, and are also exported to countries such as the United States, Canada, Romania, and Indonesia. The company is committed to establishing the "Dongsheng" image and building the "Dongsheng" brand. With a customer-centric approach and a commitment to creating maximum value for customers, we strive to make greater contributions to the oil drilling industry through proactive efforts.