08-20/2025

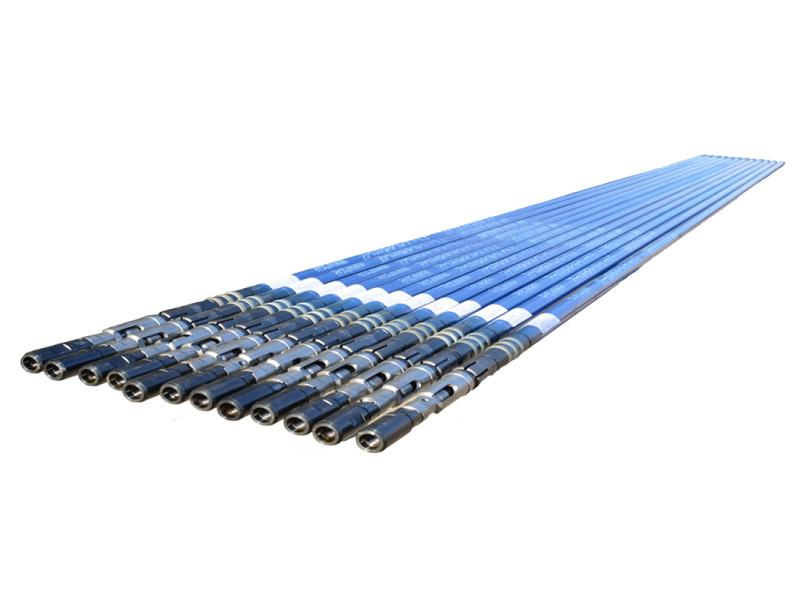

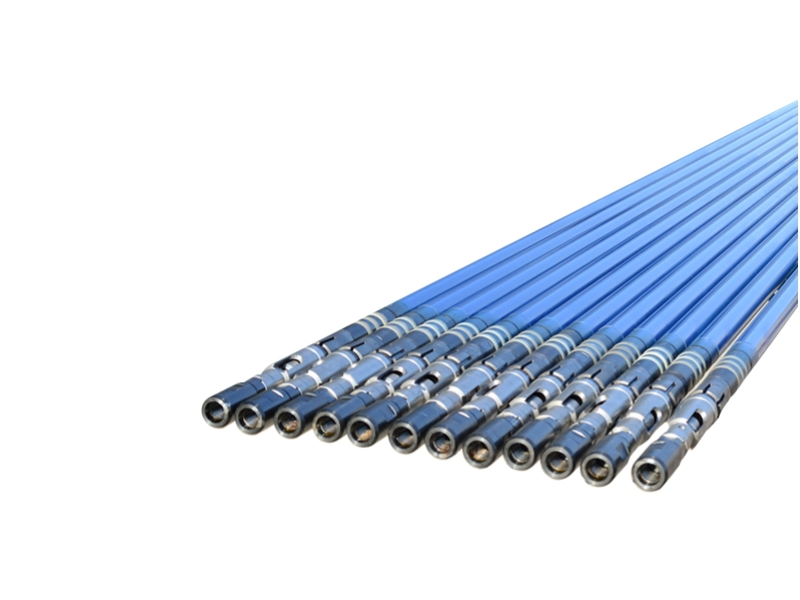

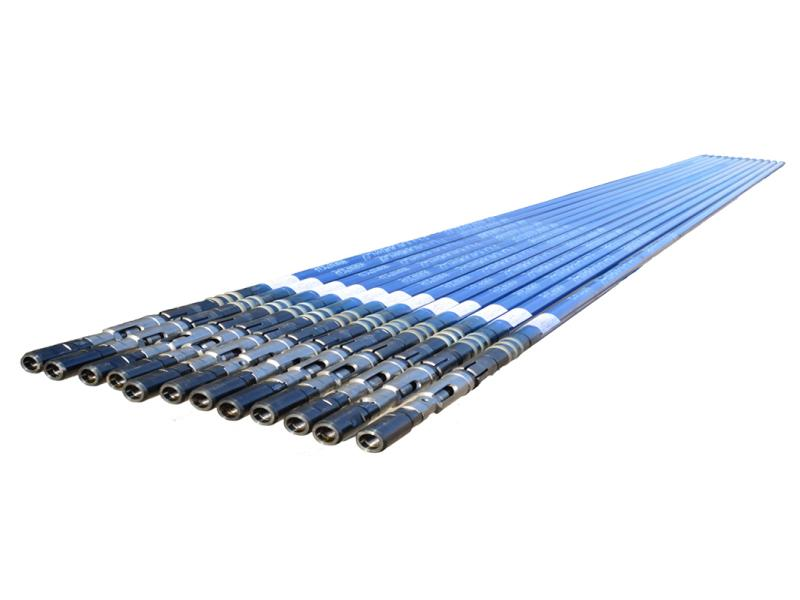

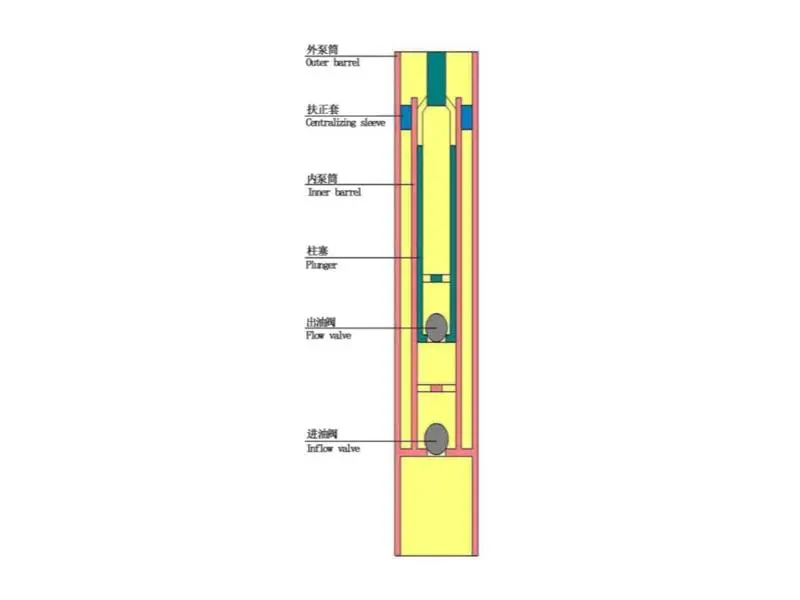

Insert rod pump is a kind of mechanical equipment widely used in the field of petroleum extraction, mainly used to extract crude oil from oil wells. The design concept of insert rod pump is based on artificial lifting technology, which mechanically lifts the fluid in the formation to the ground, thereby overcoming the natural flow difficulties caused by insufficient reservoir pressure. Insert rod pump has the characteristics of simple structure, high reliability and strong adaptability, and plays an outstanding role in low-permeability reservoirs and high-water-bearing oil wells.