Table of Contents:

Fountain Method - Harnessing Internal Energy in a Deposit

What is the driving force behind oil production under reservoir conditions?

How long can a well produce water?

In this article, I will briefly introduce the main methods of oil extraction. Oil exists in layers of porous rock (accumulators). It is in these accumulators that the oil accumulates. A second prerequisite is that the accumulators must be covered by an impermeable oil and gas seal; otherwise, the gas will evaporate and the oil will eventually turn into bitumen.

To extract oil, a well must be drilled. The well enters the oil-producing stratum, and here the fun begins—the oil must be brought to the surface somehow.

How does oil appear in the Earth? (Part 1)

There are three main methods of oil extraction (well extraction): fountain and mechanized (pump-based). Gas lift is also sometimes used, which does not use pumps but requires external energy injection. Therefore, gas lift can be considered a transitional method between fountain and mechanized extraction methods.

Fountain Method - Harnessing Internal Energy in a Deposit:

When an oil field is newly developed, the oil within it is typically under high pressure. The pressure within the formation is called formation pressure, and the pressure within the well is called bottomhole pressure. Typically, in a shut-in well, these values are consistent. In a well operating normally, the formation experiences a depression—the bottomhole pressure is lower than the formation pressure. Conversely, in a shut-in well, the formation experiences a depression—the bottomhole pressure is higher than the formation pressure. If the formation pressure is high enough, it can overcome the resistance of atmospheric pressure and force the oil out. In this case, an oil fountain is formed.

What is the driving force behind oil production under reservoir conditions?

1. Cap-of-tank model:

Anticline (dome-shaped) deposits, in particular, have a gas-filled region at the top—the gas cap.

As we all know, gas is highly compressible. When an oil well is operated, the gas begins to expand, and this is the driving force that propels oil through the wellbore to the surface.

In this case, the oil field is produced so that the natural gas in the caprock does not escape prematurely; it is included in the national reserve balance and is recovered after oil production.

2. Dissolved gas model:

In addition to the gas cap, oil also contains dissolved gas. Higher pressure increases the amount of dissolved gas. The ratio of the volume of dissolved gas to the volume or mass of oil under standard conditions is called the gas fraction (GF). For example, if the GF is 50 cubic meters per ton, this means that 50 cubic meters of gas are dissolved in every ton of oil (under standard conditions).

When the pressure drops, the gas begins to rise in the form of bubbles, carrying the oil with it. The key is to ensure that the number of bubbles is sufficient and that they are large enough; otherwise, only gas will bubble up, and the liquid will not rise.

Natural gas produced along with oil is called associated gas. Associated gas is similar to regular natural gas, but with higher concentrations. Specifically, it contains more liquefied petroleum gas (LPG, a broad fraction of light hydrocarbons, with higher propane and butane content) and condensate (pentane and higher hydrocarbons). Associated gas is a valuable feedstock for the petrochemical industry and a source of propane-butane mixtures used as fuel for gas engines.

3. Water Pressure Mode:

In this mode, the primary driving force for displacing oil to the bottom of the production well is the pressure of marginal water. Water exists at the bottom of the deposit, either as residual water from its formation or as a continuous supply of marginal water, which is connected to the surface and derived from sources such as meltwater and rainwater.

This is the most efficient oilfield operation mode, and its effective utilization allows for the extraction of large quantities of oil from the formation. However, long-term operation is only possible under one condition: continuous external water injection through a system of injection wells (a system that maintains formation pressure); otherwise, the energy source will quickly deplete.

4. Elastic Water Pressure:

In this mode, oil displacement occurs due to the elastic expansion of the oil itself, the water surrounding the reservoir, and the formation framework. This means that under the influence of the overlying rock, the oil, liquid, and rock framework are all compressed, albeit slightly. The elasticity of the liquid and the formation itself is very low. However, when the hydraulic system is large and the formation pressure is high, large amounts of liquid can be displaced from the formation into the wellbore due to liquid expansion and the reduction of pore (fracture) volume. The elastic properties of the liquid and formation are characterized by the compressibility coefficients of the liquid and formation, respectively. There is also a gravity mode, but this does not provide enough energy to lift the oil.

How long can a well continue to gushing?

This depends entirely on the oil field and the extraction method. Generally speaking, the younger the field, the more wells it has. However, the energy quickly depletes, within months or even years, forcing the use of mechanized extraction methods, which are always more expensive. There are exceptions, such as the Tengiz oil field in Kazakhstan, which was gushing for at least 21 years (1991-2010). Oil may still be flowing, but we haven't seen any information about it in a long time.

New wells in older fields also act as "gushing" wells. However, these are typically not connected to the main production pipeline because the pipeline is pressurized, typically around 20-25 atmospheres. A "gushing well" doesn't generate this pressure, so oil doesn't flow from it.

In these cases, a gas separator is installed to separate the gas from the liquid, collect the oil in a container, and then incinerate the gas. This is certainly a brutal waste of resources, but in some cases, it's cheaper to incinerate the associated gas and pay the fine than to collect and use it.

What happens when the gushing well dries up?

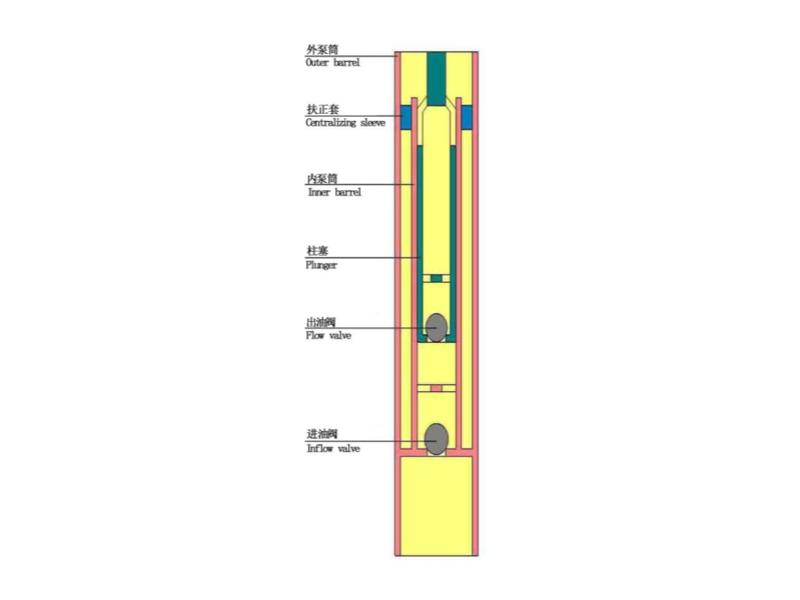

Now, only one thing remained to do—switch to a deep well oil sucker rod pump. However, in some cases, immediately switching to a pumping system can be problematic. For example, in natural gas and oil fields. Deep well oil sucker rod pumps are positive displacement pumps, primarily plunger and centrifugal. If the gas coefficient is high, the pump will fill with air, or more accurately, become aerated. This means the working chamber is filled with gas, causing the pump to run dry and quickly burn out.

To prevent this, a gas separator is installed on the pumping unit to remove free gas. Another method is to use a disperser, which is designed to break up gas inclusions in the formation fluid, creating a uniform gas-liquid mixture that is then delivered to the input of the submersible centrifugal pump.

However, this is not effective if the gas content is high. Therefore, in such cases, gas lift is used. This method eliminates the need to lower the pump and more effectively utilizes the internal energy of the dissolved gas in the formation. Gas is pumped from the surface through a series of pipelines to the bottom of the pump, where it mixes with the liquid. The injected gas mixes with gas released from the formation fluid, forming a gas-liquid mixture with a density that allows the existing pressure at the bottom of the well to be sufficient to lift the liquid to the surface through the riser.

The following section will explore the operating principles of a deep well oil sucker rod pump.

If you found this interesting, please like and subscribe.