Submersible electric pump overview:

1. Submersible electric pump composition:

Submersible electric pump consists of downhole part and uphole part . The downhole part consists of motor, protector, oil-gas separator (or inlet section), submersible pump, PSI, cable, check valve, relief valve, etc.; the downhole part of the submersible electric pump unit is a slender cylindrical structure with a length of up to tens of meters. The shafts of the motor, protector, oil-gas separator (or inlet section) and submersible pump are connected with spline sleeves, and the outer shell is connected with flange bolts. The uphole part consists of transformer, control cabinet (control station), junction box, etc.

2. Submersible electric pump principle:

The submersible electric pump unit is to lower the motor, protector, oil-gas separator (or inlet section), submersible pump and cable into the well, and the submersible pump is connected with the well pipe and the ground pipeline. After the ground power grid is connected through the transformer, control cabinet, and junction box, the power is fed to the motor through the cable, and the motor rotates to drive the submersible pump to lift the well fluid to the ground.

Power supply process of submersible electric pump unit: ground power grid → transformer → control cabinet → junction box → cable → motor.

Pumping process of submersible electric pump unit: gas separator (or inlet section) → submersible pump → check valve → drain valve → oil pipe → wellhead → oil transportation system.

3. Analysis of reasons for submersible electric pump repair:

During the operation of submersible electric pump, ground equipment is prone to failure, and the maintenance cycle is long and the cost is high; after the underground cable and motor are lowered into the well once, they cannot be used after the well repair.

4. Scope of test use:

In terms of energy consumption, the displacement is 100m3/d, the head is 1000m, the underground motor power is 45KW, and the ground voltage needs to be boosted to 1100V.

API sucker rod pump overview:

1. Structure of API sucker rod pump :

API sucker rod pump is a sleeveless integral deep well pump, which is divided into two categories: top fixed type (RHA, RWA) and bottom fixed type (RHB, RWB); the structure consists of two major parts: plunger built-in pump barrel assembly and external fixed assembly.

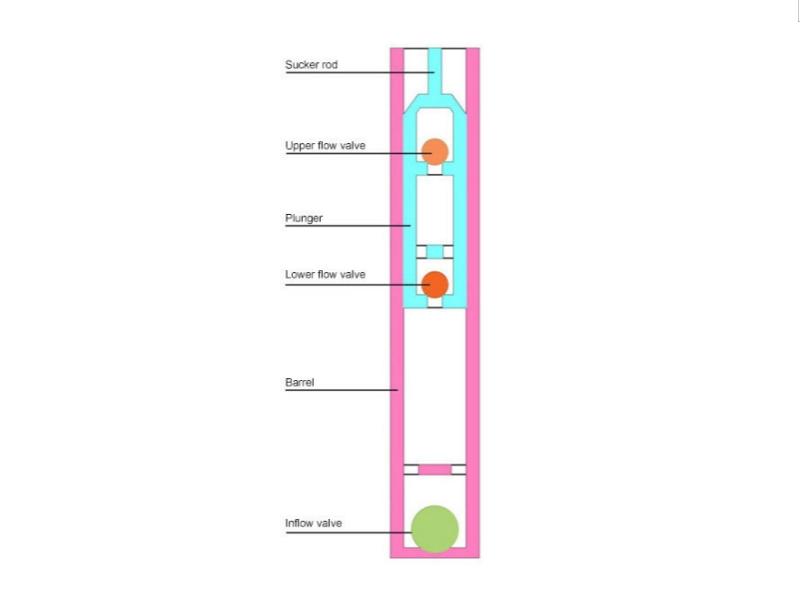

2. Working principle:

The working principle of API sucker rod pump is the same as that of tube pump, which relies on the reciprocating motion of the plunger to pump the well fluid to the ground. During the upstroke, the fixed valve and the annular valve are opened, the floating valve is closed, the well fluid washes the well pump barrel, and the liquid on the plunger is pumped to the ground; during the downstroke, the floating valve is opened, the fixed valve and the annular valve are closed to form a secondary compression, and the well fluid flows to the plunger through the floating valve.

3. Analysis of reasons for API sucker rod pump repair:

The main feature of API sucker rod pump repair is that the pump can be brought to the ground for repair by pulling out the sucker rod instead of pulling out the oil pipe, which reduces the workload and intensity, shortens the recovery time of the lying well, and improves work efficiency. The main problems of API sucker rod pump are: the pull rod of the pump is easy to wear and break; after the coal powder is stuck in the pump, the pump plunger is directly unsealed when it is unstuck; the leather cup of the pump body falls off, causing the seal to fail; the pump fixed valve leaks.

4. Scope of use:

API sucker rod pump is mainly suitable for vertical and inclined wells with small liquid production (well inclination <75°), wells with sand, coal powder and light scaling.

Difference in maintenance and operating costs:

High maintenance cost of submersible electric pumps:

Complicated surface equipment, relatively high failure rates of control cabinets, motors, etc.;

Complicated and costly replacement of downhole equipment, cables and motors are disposable;

Once maintenance is required, the downhole equipment must be pulled out as a whole, involving hoisting, power off, high-voltage power processing and other links, with high costs and time costs.

API sucker rod pump maintenance is convenient:

After the sucker rod is pulled out, the pump body can be driven up the well without pulling out the oil pipe;

The maintenance process is simpler, with low requirements for personnel and equipment;

Easy replacement of pump body parts, lower operating and maintenance costs;

However, it is necessary to regularly check the pull rod, leather cup and other vulnerable parts to prevent problems such as broken rods and seal failure.

Which scenarios are they applicable to respectively:

| Working conditions factors | Submersible electric pumps | API sucker rod pump |

| Liquid production | High-yield wells (>80m³/d) | Medium and low liquid production wells (<50m³/d) |

| Well depth | Deep wells (>1500m) | Medium and shallow wells (<2000 meters) |

| Well inclination angle | Vertical wells, slightly inclined wells | Vertical wells, inclined wells (<75°) |

| Downhole impurities | Clean well fluid | Wells containing sand, coal powder, and scale |

| Power supply conditions | Requires high-voltage power supply (such as 1100V) | Ordinary power supply (such as 380V) is sufficient |

| Maintenance frequency/convenience | Inconvenient maintenance, requires professional equipment | Easy maintenance and high efficiency |

Selection suggestions:

When selecting equipment, it is necessary to comprehensively consider factors such as liquid production, well depth, well conditions, power conditions and maintenance convenience. If you are currently in a situation where the well is deep, the liquid production is high, and there are stable high-voltage power supply conditions, you can give priority to submersible electric pumps, especially in offshore platforms or remote oilfields. If it is a medium-shallow well, a well containing sand and impurities, or a site that requires convenient maintenance, it is recommended to give priority to API sucker rod pumps, which will have lower operating costs and more flexible maintenance.

Recommended practices:

In the design stage of new wells, the oil well capacity and power matching selection plan can be integrated.

In the stage of old well transformation/inefficient well management, API sucker rod pumps can be used to control costs.

For complex well conditions or special demand scenarios, it is recommended to flexibly configure in combination with field test data.

If the above does not involve your current well conditions, you can find our technicians through the following contact information, and we will recommend the model of equipment for you based on your actual situation.

The next article is about: What is the difference between electric submersible screw pumps and tubular oil pumps?

If you are interested, you can click the link on the right!

Contact: Jason

Mobile phone: +86-13052798822

Email: jason@tldspm.com

WhatsApp: +86-15104247781