What are the advantages and disadvantages of the sucker rod pump (SRP) system? That's what I'll share today.

In the previous article, I introduced the fountain method and gas lift method for oil recovery. These two methods are typically used in the initial stages of oil field development, when internal energy or a small influx of external energy in the form of gas is sufficient to lift the oil.

However, once the internal energy is depleted, the only way to extract the oil from the reservoir is to use some type of deep well pump. There are many types of deep well pumps, but one of the following three main types is generally used in practice:

1. Sucker Rod Pump (SRP) System.

2. Rod-Driven Progressive Cavity Pump (PCP) System.

3. Electrical Submersible Pump (ESP) System.

I'll start with the most common deep-well pump type:

The pumping unit is one of the hallmarks of oil production. However, the pumping unit itself is only the above-ground portion. The entire system consists of above-ground and underground sections. The above-ground section includes the pumping unit and well tubing (Christmas tree), while the underground section includes the tubing string, sucker rod hanger, and the pump itself. The pumping unit consists of a balance beam with a folding head, a bracket to which the balance beam is attached, a large frame fixed to a reinforced concrete base, and a balance beam drive assembly consisting of an electric motor, a V-belt drive, connecting rods, and a crank. The drive activates the balance beam, causing it to move in an arc. A suspension rope is attached to the balance head, to which the first rod (called the polished rod) is attached. The movement of the balance head drives the rod hanger assembly up and down. The wellhead assembly is used to seal the polished rod, seal the tubular and annular spaces, redirect fluid flow, and suspend the oil tubing (oil well pipe).

The oil well sucker rod is a pipe with threads at the bottom and a connector at the top. These solid rolled tubes are twisted together to form a string, at the bottom of which various equipment (pumps, packers, multi-packer assemblies, feathered joints, feathered olive joints, stingers, etc.) is installed. Oil well sucker rod tubing comes in various types (smooth, thickened, different strength grades, etc.), and the choice depends on the geological and technical characteristics of the well, or sometimes simply on the availability of existing equipment and tubing. Combination strings are often used, for example, with stronger thickened tubing at the top and smooth tubing at the bottom. Or, with 73 mm diameter tubing at the top and 60 mm diameter tubing at the bottom. If the tubing types are different, specialized fittings are required to connect them.

A string of rods is placed within the pipe. These rods are steel rods with threads at both ends. Rod diameters range from 9 mm to 36 mm. Connecting fittings are used to connect rods of the same size, while adapters are used to connect rods of different sizes.

Sucker rods transmit energy from the driver to the pump. They bear the greatest loads, and most accidents are related to sucker rod damage. The constant movement of the sucker rod can cause mechanical damage where it contacts the tubing, sometimes puncturing the tubing and causing holes. To prevent this, special stabilizers and protectors made of wear-resistant plastic or rubber are installed on the sucker rod.

Sucker rod with a stabilizer:

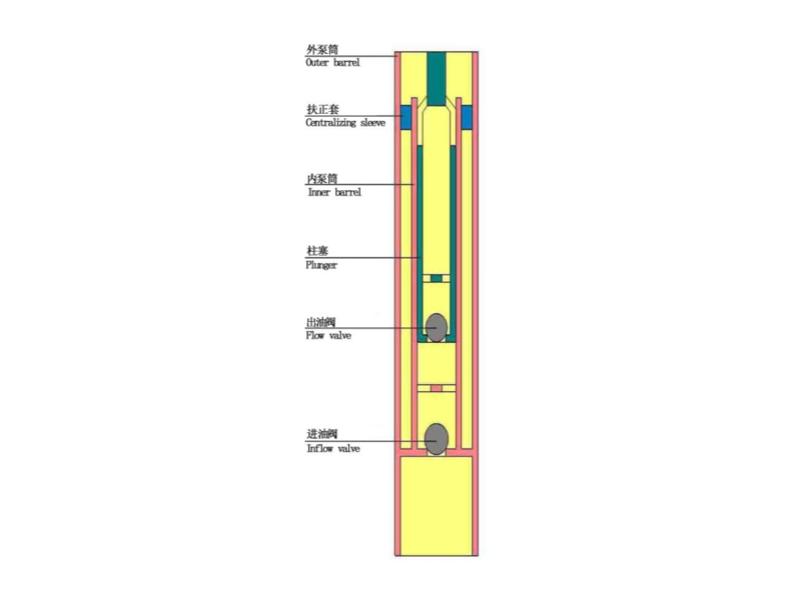

The sucker rod pump itself is located at the bottom of the tubing string. Its design is simple: a hollow cylinder with a plunger. The plunger is hollow and contains a discharge valve.

The rod string drives the plunger up and down. Two valves are also located inside the pump body: the discharge valve is located at the top of the plunger, and the suction ball valve is located at the bottom.

When the plunger moves upward, a vacuum is created below the pump, allowing liquid to enter the pump through the suction valve. When the plunger moves downward, the suction valve closes, allowing liquid to enter the tubing string through the hollow piston.

There are two types of pumps. Insertion-type sucker rod pumps are assembled and lowered. The plunger is located in the pump body and is secured in a special lock (anchor) after lowering. If a sucker rod pump is not a plug-in type, the pump body is simply lowered onto the tubing, and the plunger with valve is lowered onto the sucker rod. This type of sucker rod pump has a larger diameter and a higher well flow rate. However, the tubing must be fully lifted to raise the pump.

Plug-in sucker rod pump, whose diameter does not exceed the tubing's inner diameter, have lower productivity, but the pump can be easily removed directly from the rod for maintenance.

Advantages and disadvantages of sucker rod pumps:

The main advantage of a sucker rod pump is its simple design, which is virtually damage-free. It requires no submersible electronics or telemetry equipment. Large gas volumes reduce gas delivery, but the sucker rod pump will not burn out. It is also suitable for small-diameter wells.

Disadvantages of sucker rod pumps include complex and frequent maintenance. The rod almost always breaks, falls off, or breaks. Furthermore, repairs are time-consuming because both the tubing and the rod must be lifted simultaneously. Furthermore, wax adheres to the rod, making the work messy and unpleasant. The plunger stroke is also difficult to adjust. Furthermore, their low feed rates make them unsuitable for wells deeper than 3,000 meters and for inclined wells—the rod simply cuts through the pipe at the point of curvature.

This is why sucker rod pumps are actively replacing electrostatic precipitators (ESPs). However, I'll write about them another time; for now, I'll briefly describe the structure and working principle of screw pumps.

Screw pump units also have a surface section, but rather than a pumping mechanism, they feature a separate motor and transmission that rotates the drive head, to which the rod column is attached.

However, the rod does not reciprocate, but rather moves in a circular motion. The pump itself is a pair of screws. The moving element is an Archimedean screw, and the stator is an internal spiral. The continuous meshing between the collar and the spiral creates multiple independent cavities.

As the moving element rotates, the volume of the sinus cavity on the suction side increases, creating a vacuum, which fills the cavity with the pumped liquid. Further movement of the rotor moves the fluid toward the pressure main. Due to the generated vacuum, the fluid is drawn from the well and then delivered to the pressure pipeline.

The advantage of the screw pump unit is that the failure rate of the pump is much lower than that of the plunger pump, and it is the most economical. However, the pump itself is much more expensive than the sucker rod pump system.