09-01/2025

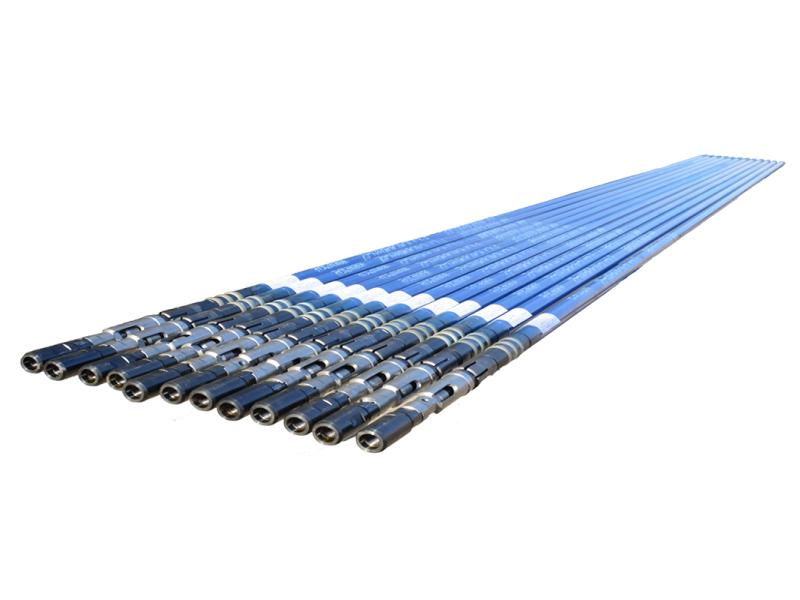

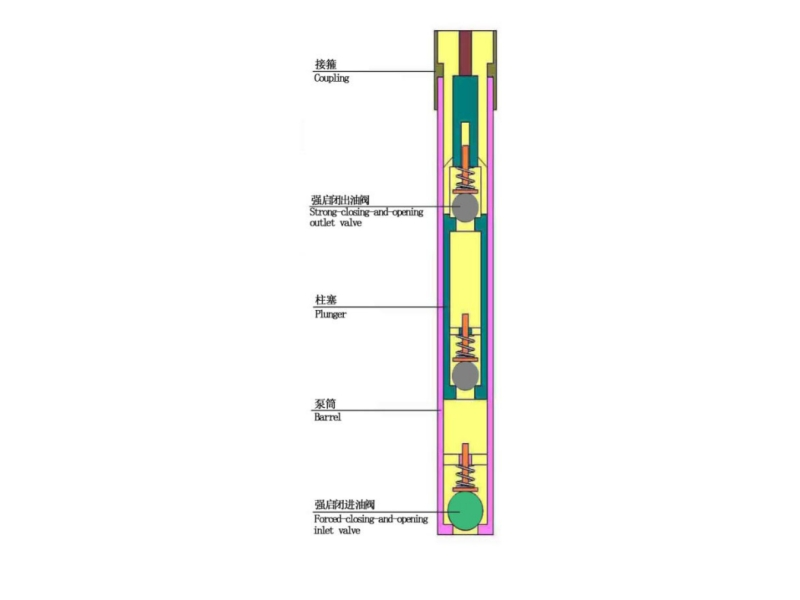

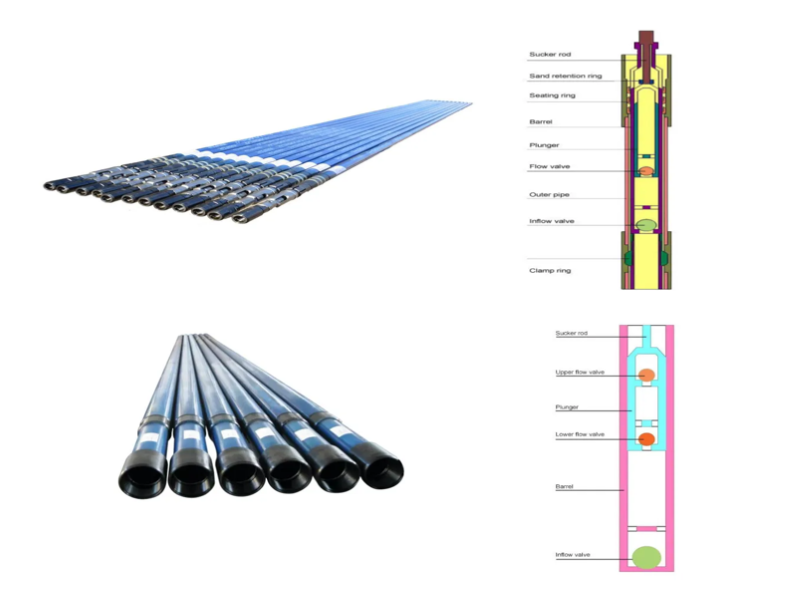

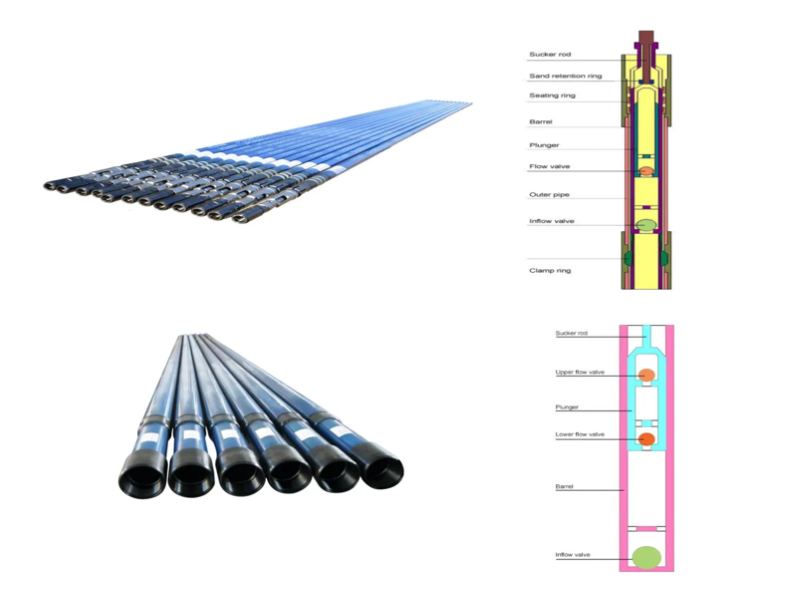

In the process of oilfield development, sucker rod pump has always played a very important role. This kind of device, which drives the downhole plunger to work through the ground pumping unit, is like a loyal partner, accompanying the oil well through the middle and late stages of production attenuation. The core value of sucker rod pump lies in its reliability, durability and easy maintenance, especially suitable for the continuous production of conventional onshore oil fields. When the natural energy of the oil well is gradually exhausted, sucker rod pump becomes the key pillar to maintain stable crude oil production.