Table of Contents:

Why Use an Inclined Well Sucker Rod Pump?

Challenges of Inclined Well Pumping

Application Scenarios of Inclined Well Sucker Rod Pumps

Comparison of Common Artificial Lift Methods

Structure and Features of Inclined Well Sucker Rod Pumps

Pump Types and Selection

How to Choose the Right Inclined Well Sucker Rod Pump

Conclusion and Recommendations

In oil production, rod pumping remains the most common method of artificial lift. However, traditional vertical well pumping methods face many challenges in inclined well environments. Inclined well sucker rod pumps are designed to address these challenges.

2.. Challenges of Inclined Well Pumping:

Compared to vertical wells, inclined well pumping presents the following challenges:

Rod-Tubing Friction: Increased friction between the rod and tubing leads to severe wear.

Rod String Curvature: Lateral displacement of the rod in the wellbore causes coupling of longitudinal and lateral vibrations, leading to rod buckling or even fracture.

Shortened Equipment Life: Long-term friction and stress concentration accelerate equipment failure.

Thus, inclined well environments place higher demands on the design and selection of pumps.

3. Application Scenarios of Inclined Well Sucker Rod Pumps:

Inclined wells with an inclination of less than 45°.

Wells with high gas content.

Oilfields requiring reduced equipment wear and improved pump efficiency.

4. Comparison of Common Artificial Lift Methods:

Sucker Rod Pumps (Beam Pumps): With a long history, high reliability, and a wide range of applications, they are the primary method for producing oil in inclined wells.

Gas Lift Systems: Reduce the weight of the liquid column through gas injection, but are inefficient in deep and inclined wells.

Progressive Cavity Pumps: Suitable for high-viscosity crude oil, but not suitable for deep, inclined wells and susceptible to damage from abrasive materials.

Electrical Submersible Pumps: High production capacity, but complex maintenance, and ineffective in wells with high gas content.

Among these methods, sucker rod pumps are the preferred solution for inclined well extraction due to their maturity and controllability.

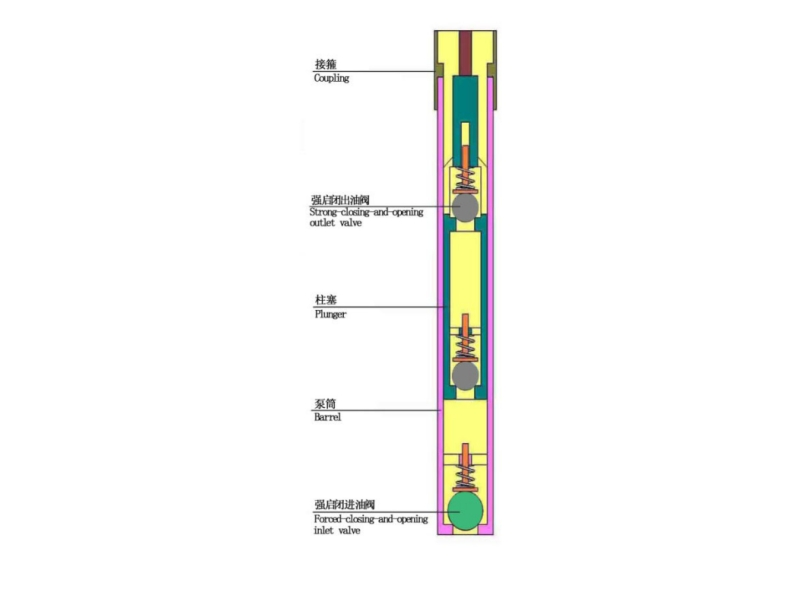

5. Structure and Features of Inclined Well Sucker Rod Pumps:

Rotary Plunger: Automatically rotates during operation to prevent deflection and wear. Special valve ball design: The floating and stationary valves can retract promptly, ensuring pump efficiency.

Anti-gas lock design: The improved hydraulic valve and valve ball structure eliminates the gas lock problem of traditional pumps and improves efficiency.

6.Inclined Well Sucker Rod Pump Types:

Fixed Barrel Pump:

Bottom-anchored: Suitable for deep wells, high efficiency, but prone to sand accumulation.

Top-anchored: Suitable for shallow wells, simple structure, but susceptible to air shock.

Floating Barrel Pump:

Corrosion-resistant and wear-resistant, suitable for sand-laden wells, but more susceptible to gas lock.

Forced-opening valve insertion pump

Inserts into tubing for easy maintenance.

Suitable for deep wells, especially in environments prone to gas lock.

7.How to Choose the Right Inclined Well Sucker Rod Pump:

The following factors should be considered when selecting a pump:

Media Characteristics: Whether sand or gas is present, and crude oil viscosity.

Well Depth and Inclination: For deep and highly deviated wells, consider rod string stress and pump durability. Production requirements: Select a pump with the appropriate displacement based on target production.

Corrosion resistance: Choose a compatible pump material based on the fluid's chemical composition.

The proper selection and application of an inclined well sucker rod pump not only effectively improves oil recovery efficiency but also significantly reduces equipment wear and maintenance costs. In practical applications, a comprehensive consideration should be made based on well conditions, fluid properties, and production targets.

Our company has specialized in inclined well sucker rod pump and artificial lift system solutions for many years. Our product range includes various types, including insertable pumps, and features innovative designs such as anti-wear and anti-gas lock. Our pumps have been successfully deployed in numerous complex well conditions, helping customers reduce operating costs and improve oil production efficiency. If you are looking for the right inclined well sucker rod pump, we will provide you with the best selection and technical support.