The main difference between tubing pumps and insert rod pumps is that tubing pumps have a simple structure and low cost. The diameter of the pump that can be inserted under the same oil pipe diameter is larger than that of insert rod pumps, so the displacement is large. However, when inspecting the pump, the oil pipe must be started, and the workload of repairing the well is large. It is suitable for oil wells with small depth and high production. Insert rod pumps are convenient for pump inspection, but have a complex structure and high manufacturing cost. The diameter of the pump that can be inserted under the same oil pipe diameter is smaller than that of tubing pumps. Insert rod pumps are suitable for oil wells with large depth and low production.

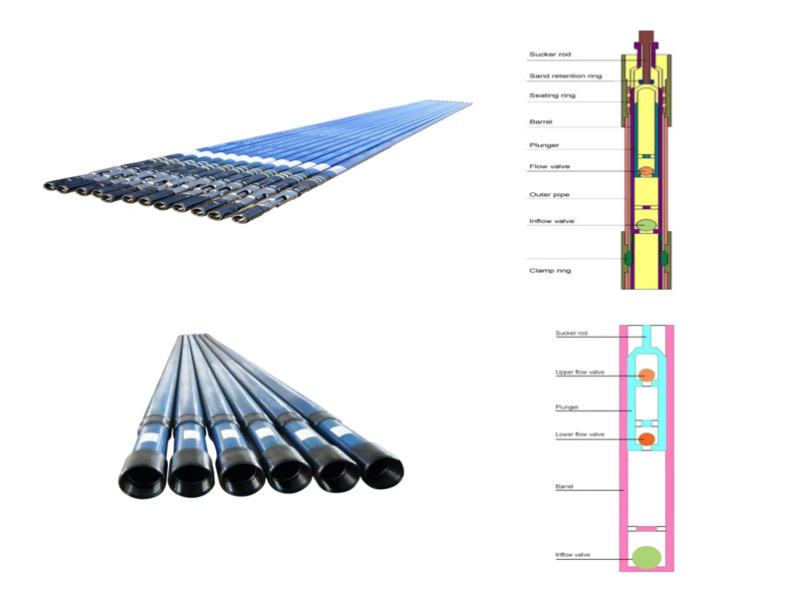

(1) Tubing pump:

The tubing pump is also called tubing pump. Its characteristic is that the outer tube, bushing, and suction valve are assembled on the ground and connected to the lower part of the oil pipe. Tubing pump first enters the well, and then the piston equipped with the discharge valve is pushed into the pump barrel through the oil pipe by the sucker rod.

The bushing is processed into several parts by the material and lined inside the outer tube. The piston is a hollow cylinder made of seamless steel pipe. The outer surface is smooth and has an annular groove. Its function is to trap sand particles that enter between the piston and bushing in the groove, preventing them from wearing the piston and bushing. The oil stored in the groove lubricates the piston surface.

When the pump is started, a removable suction valve (fixed valve) can be used to drain the oil from the tubing. By lowering the rod string, the catch at the lower end of the piston engages the removable head of the suction valve, lifting the valve. However, because the removable head of the suction valve occupies space within the pump, the pump's anti-surge distance and clearance volume are large, making it susceptible to gas flow and reducing pump efficiency. Currently, most wells that feed tubing pumps are equipped with an oil drain at the bottom of the tubing. The oil in the tubing is drained by opening the oil drain. In wells that feed large pumps, the piston diameter is larger than the tubing inner diameter, preventing access to the piston through the tubing. Instead, the piston and tubing are first lowered into the well, then fed into the sucker rod string, where tubing pump is connected to the piston in the pump using a device called a disconnector.

These pumps are characterized by their simple structure, ease of fabrication, and low cost. Under the same tubing diameter, the diameter of the pump that allows one person to pump is larger than that of the insert rod pump, so the displacement is large. However, when checking and replacing the pump, the tubing needs to be started, and the workload of well maintenance is large. Tubing pump is suitable for high-yield, shallow oil wells. Tubing pumps can be divided into double-valve and three-valve tubing pumps according to the number of valves.

The insert rod pump is also called an insert pump. The fixed-tube top fixed insert rod pump is characterized by two inner and outer working cylinders. The upper end of the outer working cylinder is equipped with a cone seat and a retaining ring (the position of the retaining ring is the depth of the pump). When lowering the pump, the outer working cylinder is lowered into the well together with the tubing, and then the inner working cylinder with a bushing and a piston is connected to the lower end of the sucker rod, lowered into the outer working cylinder, and fixed by the retaining ring. In addition, there are fixed-tube bottom fixed insert rod pumps with a fixed point at the bottom of the pump barrel, and fixed-cylinder bottom fixed insert rod pumps. The piston is fixed at the bottom, and the pump barrel is driven up and down by the sucker rod. When inspecting the pump, the inner working cylinder is pulled out via the sucker rod, rather than the tubing.

Advantages and Disadvantages of Insert Rod Pumps:

Insert rod pumpsare easy to inspect, but they are complex, difficult to manufacture, and expensive. The diameter of the pump that can fit into the same tubing diameter is smaller than that of a tubing pump, resulting in a lower displacement. Therefore, insert rod pumps are suitable for deep, low-yield wells.

Tubbing pumps are suitable for shallow, high-yield wells, while insert rod pumps are more suitable for deep, low-yield wells. The choice ultimately depends on the well's depth, production rate, sand content, and ease of inspection and maintenance.

In our long-term production experience, we've found that many customers often struggle with pump selection: Which type of pump should they choose to meet their production needs while reducing maintenance costs? We not only offer a variety of tubing and insert rod pump models, but can also tailor solutions to suit different well conditions.

We hope this article will help you gain a clearer understanding of these two types of pumps. If you encounter any problems during actual use or need more professional selection advice, please feel free to contact us. We are always willing to work with you to help your oil wells achieve stable and efficient production.