API type tubing pumps and API type rod pumps are two common types of mechanical oil production equipment. Due to their structural differences, their application performance in different well conditions varies. Choosing the right pump based on well depth, production rate, and ease of maintenance has always been a core concern for oilfield engineers and production units. This article will provide an in-depth analysis of the structural characteristics and application scenarios of API type tubing pumps and API type rod pumps, helping you quickly compare their advantages and limitations.

Comparison of API type tubing pumps and API type rod pumps:

API type tubing pumps and API type rod pumps each have their own unique advantages. API type tubing pumps are known for their simple structure and low cost, enabling the use of larger pump diameters for the same tubing diameter, achieving high displacement. However, they require the tubing to be started for inspection, making them suitable for shallow, high-yield wells. While API type rod pumps are more complex and relatively expensive to manufacture, they offer easier inspection and are suitable for deep, low-yield wells.

Features and applications of API type tubing pumps:

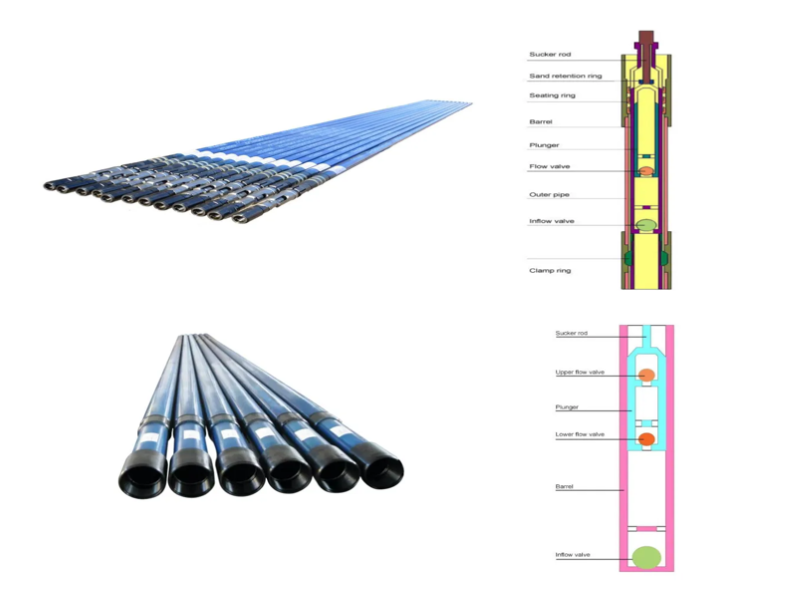

API-type tubing pumps, also known as tubing pumps, feature a unique design. Components including the outer barrel, bushing, and suction valve are preassembled on the surface and then connected to the lower portion of the tubing. During operation, the pump is lowered into the wellbore. The pump rod then drives a piston equipped with a discharge valve through the tubing into the pump barrel.

The bushing is a multi-section component machined from a specific material and installed inside the outer barrel. The piston is a hollow cylinder crafted from seamless steel tubing. Its outer surface is specially treated to be smooth and features annular grooves. These grooves are designed to trap sand particles that enter the space between the piston and bushing, effectively preventing wear on both. They also lubricate the piston surface by storing oil, reducing friction.

During the pump startup phase, a removable suction valve (fixed valve) is often used to drain oil from the tubing. By operating the rod string, the catch at the lower end of the piston engages the removable head of the suction valve, lifting the valve. However, it's worth noting that because the suction valve overshot occupies some space within the pump, the pump's anti-surge distance and clearance volume are relatively large, making it susceptible to gas impacts and thus reducing pump efficiency.

Currently, most wells accessing tubing pumps are installed with an oil drainer at the bottom of the tubing. Opening the oil drainer effectively drains the oil from the tubing. However, in some wells accessing large pumps, the piston's diameter exceeds the tubing's inner diameter, preventing it from being pumped through the tubing. To address this issue, a common approach is to first lower the piston into the well along with the tubing, then insert the rod string and connect it to the piston in the pump using a disconnector.

API type tubing pumps are characterized by their simple structure, ease of fabrication, and affordability. Given the same tubing diameter, API type tubing pump can accommodate larger pump diameters than API type rod pumps, resulting in higher displacement. However, their disadvantage is that maintenance requires priming the tubing, resulting in a relatively large downhole maintenance workload. API type tubing pumps are particularly suitable for high-production, shallow wells. API type tubing pumps can be categorized as two-valve or three-valve types, depending on the number of valves.

API type rod pump features and applications:

API type rod pumps, also known as plug-in pumps, feature a design with two inner and outer mandrels. The upper end of the outer mandrel is equipped with a cone seat and a retaining ring to determine the pump's depth. During installation, the outer mandrel is lowered into the well along with the tubing. The inner mandrel, with a bushing and piston, is then attached to the lower end of the sucker rod and lowered into the outer mandrel, secured by a retaining ring. There are also fixed-barrel-bottom-mounted API type rod pumps, with the fixing point located at the bottom of the pump barrel, and movable-cylinder-mounted API type rod pumps. Both types of pumps use a piston fixed at the bottom, with the pump barrel reciprocating up and down via the sucker rod.

When inspecting the pump, the inner mandrel can be removed via the sucker rod, without removing the tubing. API type rod pumps are known for their ease of inspection, but their relatively complex structure and manufacturing challenges increase costs. Under the same tubing diameter conditions, the pump diameter that API type rod pumps can accommodate is smaller than that of API type tubing pumps, which limits their displacement. Therefore, API type rod pumps are more suitable for deep wells with lower production.