08-24/2025

Today, Dongsheng will explain which pump is best for pumping crude oil. Please follow us for a closer look.

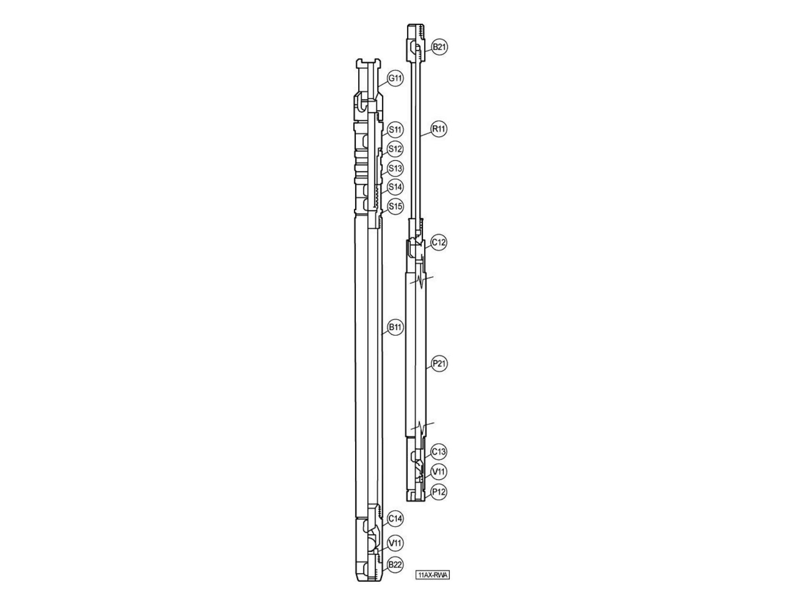

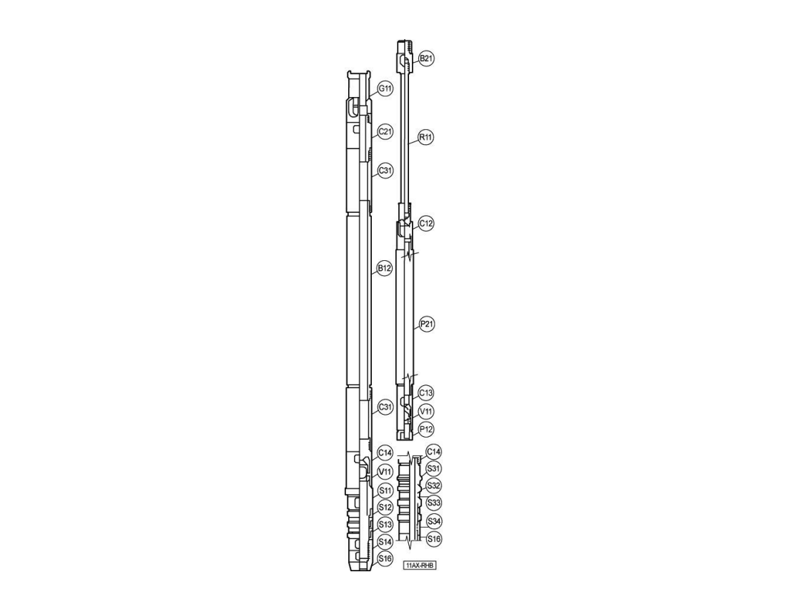

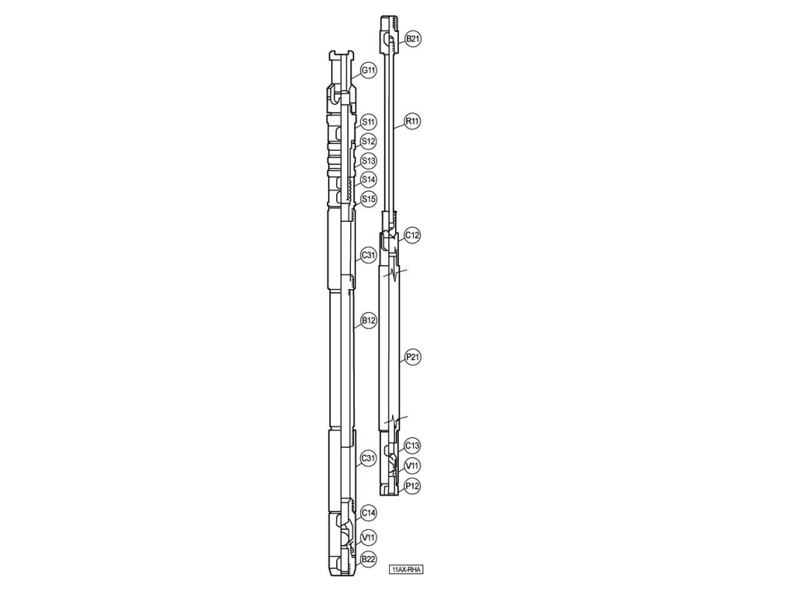

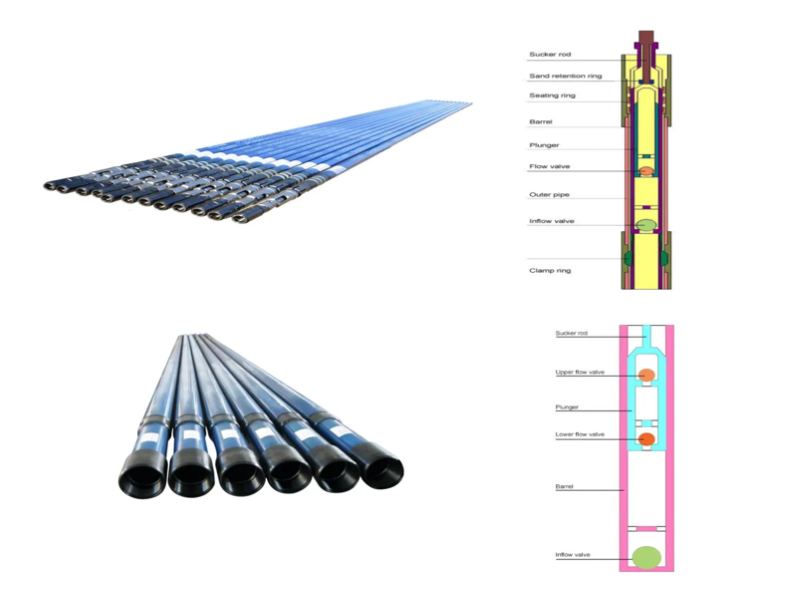

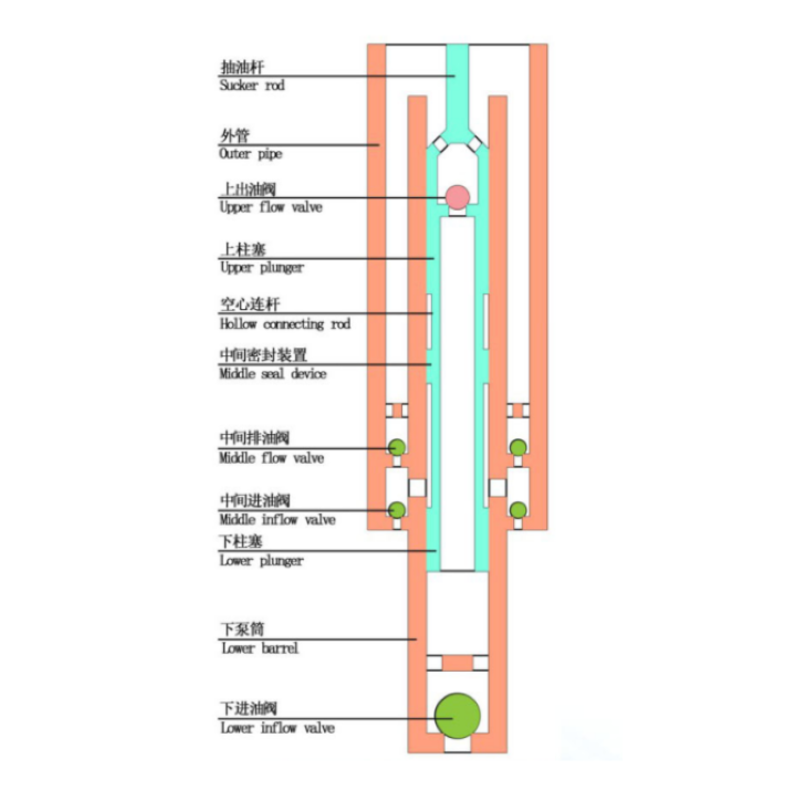

Because crude oil contains a high amount of gas, using a conventional pump can cause cavitation. This is undesirable. Therefore, a pump that can pump crude oil without cavitation is required. So, which pumps are safe from cavitation when pumping crude oil? There are many types of pumps, including insert rod pumps, pneumatic crude oil pumps, cam rotor crude oil pumps, gas-liquid mixing self-priming crude oil pumps, gear crude oil pumps, and more. To help you understand which pumps are best for pumping crude oil, Dongsheng will use the insert rod pump as a specific example.