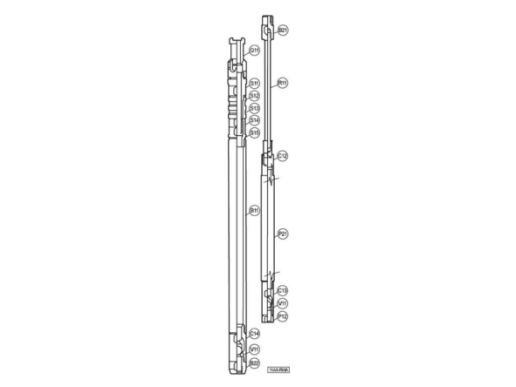

RWA Insert Rod Pump is a rod-type oil pump designed according to API SPEC 11AX (or GB/T18607) standard. According to the support and fixed form of the pump, it can be divided into three categories: moving cylinder type bottom fixed rod type oil pump (RWT or RHT), fixed cylinder type bottom fixed rod type oil pump (RWB or RHB or RXB), fixed cylinder type top fixed rod type oil pump (RWA or RHA).

Table of contents:

The model meaning of RWA Insert Rod Pump

How RWA Insert Rod Pump works

Differences between RWA, RAB, RWT

Advantages of RWA Insert Rod Pump

Applicable scenarios of RWA Insert Rod Pump

The model meaning of RWA Insert Rod Pump:

R: Rod type

W: External support

A: Fixed cylinder type, fixed top

How RWA Insert Rod Pump works:

RWA Insert Rod Pump is equipped with a leather bowl support joint N11, the leather bowl support joint N11 is connected to the tubing column, and the tubing column goes down to the bottom of the well together.The plunger assembly is connected to the sucker rod column and takes the pump as a whole down to the position of the support joint N11. The pump is fixed in the leather bowl support joint N11 by means of external force, and the plunger assembly reciprocates up and down with the sucker rod column to realize the pumping work.

Differences between RWA, RAB, RWT:

| Model number | Main features | Applicable scenarios | Maintenance requirements |

| RWA | Standard plug-in rod pump, with fixed valve design, simple structure and easy installation; medium efficiency and general wear resistance. | It is suitable for medium and shallow wells (depth <1500 meters) and conventional crude oil extraction, such as low-viscosity oil wells or stable formations. | The maintenance frequency is high (checked every 3-6 months), and the valve balls and seals need to be replaced regularly. |

| RWB | Wear-resistant and sand-proof rod pump, equipped with reinforced coating and movable valve system; strong wear resistance, good corrosion resistance, and can handle sand-containing or corrosive fluids. | Suitable for deep wells (depth >1500 meters), high sand content or corrosive environments, such as shale oil wells or offshore oil fields. | The maintenance cycle is long (every 6-12 months), focusing on checking coating wear and valve components, and the cost is higher. |

| RWT | High-efficiency sealed rod pump, using two-stage sealing and optimized flow channel design; high efficiency, low leakage risk, suitable for high-yield wells. | It is aimed at high-yield wells, high-pressure or scenarios that require high sealing, such as natural gas associated wells or high-temperature reservoirs. | The maintenance requirements are low (every 9-12 months), but professional tools are required to test the sealing performance to avoid frequent disassembly. |

Advantages of RWA Insert Rod Pump:

As an efficient oil production equipment, RWA oil pumps show significant advantages in oilfield production with technological innovation and practical design.

1.High efficiency and energy saving, improve oil recovery efficiency:

Using an improved pump cylinder and plunger mating structure, the leakage is reduced by more than 30%, and the volumetric efficiency is stable at more than 85%, which is 5%-12% higher than the daily oil increase of a single well of a traditional oil pump.At the same time, through the design of lightweight transmission components, the energy consumption ratio is reduced by 15%-20%, and long-term operation can significantly reduce the cost of electricity in oil fields.

2.Super adaptable, adapt to complex working conditions:

It has the ability to adjust the displacement of a wide range (5-50m3/d), which can flexibly match complex reservoirs such as high viscosity, sand, and gas.The pump body adopts bimetal composite coating, which improves wear resistance and corrosion resistance by 2 times. In oil wells with high mineralization and sulfur-containing media, the service life is extended to 3-5 years, reducing the frequency of pump inspections.

3.Intelligent and convenient, reduce operation and maintenance costs:

The RWA oil pump integrates built-in sensors, which can monitor pump condition, load, displacement and other data in real time, support remote diagnosis and early warning, and avoid unplanned downtime.In addition, the quick-release connection structure is adopted, the operating time of the inspection pump is shortened to 1/3 of that of traditional equipment, and the annual operation and maintenance cost of a single well is reduced by about 20,000 yuan.

4.Safe and reliable, in line with industry standards:

The whole RWA oil pump machine has passed API 11AX certification, and the key components are designed to be anti-release and anti-stuck. It operates stably in deep wells (≤3000m) and inclined wells (well slope ≤45°), and the failure rate is less than 1%, which provides a reliable guarantee for the safe production of oil fields.

Applicable scenarios of RWA Insert Rod Pump:

1.Conventional medium and shallow reservoirs

The core advantage scenario of RWA pump.It is suitable for shallow development with stable formation and good crude oil fluidity.Its structure is simple and reliable, and it can maintain stable pumping efficiency for a long time in a mild environment without severe geological disturbances and strong corrosive media.The investment and operation and maintenance costs are significantly lower than that of special pump types.

2.Maintenance of low-yield old wells:

In the middle and late oil fields with declining production, RWA pumps are the economical choice.When the liquid supply capacity of the oil well decreases and the well shaft is in good condition, its moderate displacement characteristics can avoid energy waste, while tolerating mild downhole wear (such as trace amounts of sand), and the cost performance is better than that of high-performance pumps.

3.Marginal oilfield development:

For edge blocks with small reserves and limited investment, RWA Insert Rod Pump's low procurement cost and rapid production advantages are particularly prominent.Without the need for complex installation processes, rapid cost recovery can be achieved, which is a pragmatic choice to reduce initial risks.

4.Low gas interference oil well:

It is suitable for reservoirs where dissolved gas is mainly driven and there is no free gas channeling.The fixed valve is designed to open and close reliably when the gas content is low, which can effectively maintain the pump efficiency.If the gas-oil ratio is significantly increased, you need to switch to a pump type with stronger air lock resistance.

5.Disable scene alerts:

RWA Insert Rod Pump cannot be used in the following working conditions:

Highly corrosive environment (such as hydrogen sulfide and carbon dioxide);

Crude oil with high viscosity or easy to wax;

Large slope well or horizontal well;

High-yield or high-pressure wells.