In the field of oilfield development, choosing the right lifting equipment is very important to maintain stable oil well production and improve recovery. In recent years, insert rod pump, as an efficient and adaptable mechanical oil production equipment, has shown significant advantages under specific reservoir conditions. Its application scenarios are receiving widespread attention and practical testing from Tieling Dongsheng Petroleum Co., Ltd. and other companies in the industry.

Basic introduction of insert rod pump:

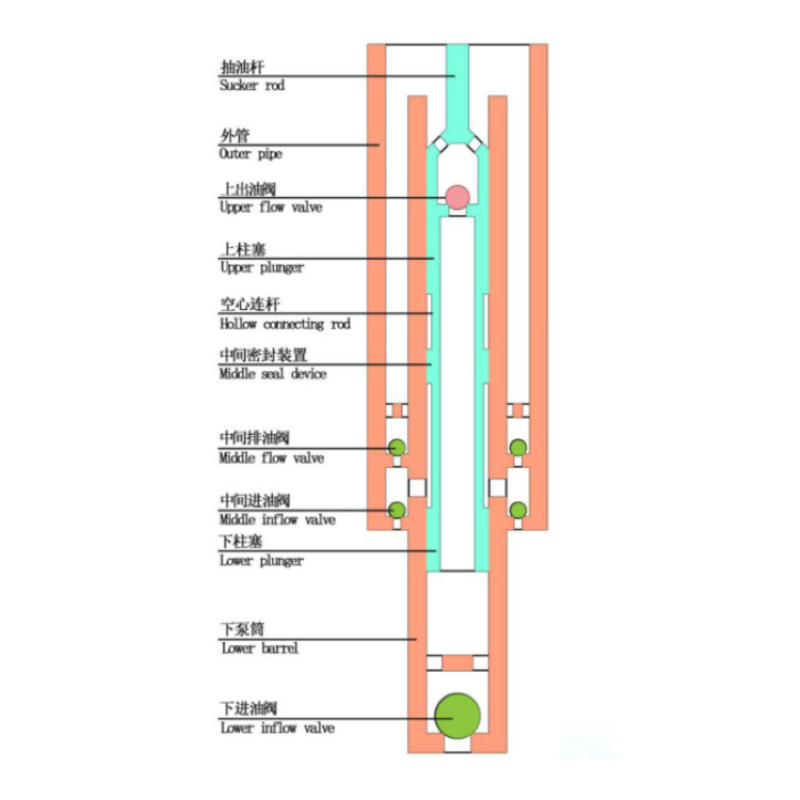

The core design of insert rod pump lies in its “plug-in” structure. Unlike traditional tubular pumps, which require the entire pump cylinder to be lowered into the well along with the tubing, the pump cylinder (working cylinder) of insert rod pump is pre-fixed to the tubing column, while the piston (plunger) and fixed valve (swimming valve) of the pump are used as an integral part. Directly “inserted” into the fixed working cylinder through the sucker rod column. This unique structure brings significant operating advantages and ease of maintenance.

Ⅰ. "Stabilizer” for complex well conditions:

The most prominent application value of insert rod pump is reflected in dealing with complex well conditions:

Inclined and horizontal wells: In directional wells, large-slope wells or horizontal well sections, conventional pumps have high maintenance costs and long cycles due to difficult lifting and descending operations and easy wear and tear. The operation method of insert rod pump only needs to lift the pump core (plunger assembly) through the sucker rod, without the need to lift a heavy oil pipe column, which greatly simplifies the operation process and reduces the operation risk and cost, especially suitable for the efficient management of such complex trajectory wells.

High-sand wells: Sand particles are the “natural enemy” of downhole pumps. Insert rod pump usually uses more wear-resistant materials to manufacture plungers and pump barrels, and its structural design helps reduce the risk of sand particles scouring the sealing pair and jamming the pump. When a sand jam does occur, it is much more convenient to clean up or replace the pump core than to remove the entire oil pipe, which can significantly reduce the shutdown time of the oil well.

Heavy oil wells: For heavy oil with higher viscosity, insert rod pump can provide sufficient pump efficiency and lift by optimizing the pump gap and adopting special surface treatment processes (such as chrome plating, spray welding alloys, etc.). At the same time, its easy-to-maintain characteristics also facilitate regular inspection and maintenance.

Deep and high temperature wells: Mature design and material selection enable insert rod pump to adapt to deeper pump hanging depths and higher downhole temperature environments, ensuring long-term stable operation under harsh conditions.

Ⅱ.A “booster” for cost reduction and efficiency:

The economic benefits of insert rod pump are directly reflected in the significant reduction in operating costs and downtime.:

The efficiency of pump inspection operations is doubled: when performing conventional pump inspections, replacing plungers or fixing valves, only the pumping rod and pump core need to be removed, avoiding the large-scale workover equipment required for oil pipeline operations, longer operating cycles and higher labor and material costs. In the practical application of Tieling Dongsheng Oilfield, its efficiency advantages have been verified many times.

Reduce tubing damage: Frequent lifting and lowering of tubing is an important cause of tubing screw damage, deformation and even scrap. The operating mode of insert rod pump significantly reduces the number of oil pipe starts, effectively extends the service life of the oil pipe, and saves material costs.

Improve the well opening time rate: Shorter pump inspection cycles mean that the well can resume production faster, which directly improves the overall well opening time rate and production contribution of the oilfield. This is of great significance for stabilizing the production of old oil fields and tapping the remaining oil potential.

With the deepening of oilfield development, the proportion of complex and inefficient wells has increased, and higher requirements have been put forward for the efficiency, adaptability and economy of lifting equipment. With its unique structural design, insert rod pump has shown strong vitality and broad application prospects in the mining of complex and challenging reservoirs such as inclined wells, horizontal wells, sand wells, and heavy oil wells. Tieling Dongsheng Petroleum Co., Ltd. will continue to deepen the research and application of advanced lifting technologies such as insert rod pump, and continue to improve the efficiency of oilfield development through continuous technological innovation and management strengthening, and contribute to the protection of national energy security. Tieling strength. Choosing the appropriate insert rod pump solution is becoming one of the important technical paths for oil fields to achieve precise and efficient mining.