The production of a well often depends not only on the oil supply capacity of the oil layer itself, but also on the performance of the pump efficiency. The pump efficiency directly determines whether the unit energy consumption can be converted into more crude oil output. There are many factors that affect the API tubing pump efficiency, but from the three basic links of deep well API tubing pump operation (piston volume, crude oil entering the pump and crude oil being discharged from the pump), it can be summarized into the following three aspects.

(1) Elastic expansion and contraction of the sucker rod string and the tubing string.

Due to the working characteristics of deep well API tubing pump , the sucker rod string and the tubing string are subjected to alternating loads during operation, resulting in elastic expansion and contraction, making the piston stroke smaller than the rod stroke, thereby reducing the piston volume.

(2) The influence of gas and insufficiency.

When the oil-gas mixture is sucked into the API tubing pump, the gas occupies part of the space left by the piston, and the oil does not have time to enter the pump. Or when the pump displacement is greater than the oil supply capacity of the oil layer, the amount of oil entering the pump will also be reduced.

(3) The impact of leakage.

The gap between the piston and the bushing and the leakage between the valve and other connecting parts will reduce the actual displacement. As long as the manufacturing quality and assembly quality of the pump are guaranteed, the impact of leakage will be small within a certain period of time after the pump is installed. However, when the liquid is corrosive or contains sand, the leakage will increase rapidly due to corrosion and wear on the pump. Wax deposition and sand deposition in the pump will cause the valve to close loosely or even get stuck, seriously damaging the operation of the pump. In these cases, in addition to improving the pump structure and improving the pump's corrosion resistance, the main measures are to take anti-sand and anti-wax measures, and to regularly inspect the pump to maintain the normal operation of the pump. Measures to improve the efficiency of API tubing pumps to improve the efficiency of API tubing pumps, it is necessary to try to reduce the impact of the above three aspects. 1. The Impact of the Elastic Deflection of the Sucker Rod and Tubing on the Piston Stroke. A piston stroke smaller than the polished rod stroke is an inevitable factor contributing to a pump efficiency less than unity. The greater the elastic deflection of the rod and tubing string, the greater the difference between the piston stroke and the polished rod stroke, and the lower the pump efficiency. The magnitude of the elastic deformation varies depending on the loads on the rod string. As previously mentioned, the main loads borne by the rod string include: the weight of the rod string and the weight of the liquid column above the piston (collectively referred to as static load), the inertial load of the rod string and the liquid column, and the vibration load of the rod string (collectively referred to as dynamic load). The following section examines the elastic deformation of the rod string and tubing caused by these loads, as well as their impact on the piston stroke.

The Impact of Gas on the Efficiency of API Tubing Pumps:

During the production period of deep-well API tubing pumps, most oil fields operate at a flowing pressure below the saturation pressure. Even when operating above the saturation pressure, the pump inlet pressure remains below the saturation pressure. Therefore, when pumping, both gas and liquid are always fed into the pump at the same time. Gas entering the pump will inevitably reduce the amount of liquid entering the pump and reduce pump efficiency. When the gas effect is serious, "gas lock" may occur, that is, during pumping, due to the compression and expansion of gas in the pump, the suction and discharge valves cannot be opened, resulting in the phenomenon of no oil being pumped out. If the oil layer energy is low or the crude oil viscosity is high, the pump suction resistance is very large. Often, the piston begins to move downward before the oil fills the pump barrel, resulting in the so-called "underfilling phenomenon", thereby reducing pump efficiency. For this situation, it is generally possible to deepen the pump hanger, increase the submergence, or select reasonable pumping parameters to adapt to the oil supply capacity of the oil layer. For heavy oil, viscosity reduction measures can also be taken. 3. Leakage effect Leakage that affects the efficiency of API tubing pumps includes:

(1) Discharge part leakage. Leakage in the gap between the piston and the bushing, and leakage in the floating valve will reduce the amount of oil discharged from the API tubing pump.

(2) Suction part leakage. Leakage from the fixed valve will reduce the amount of oil entering the API tubing pump.

(3) Leakage from other parts. Even if the API tubing pump is working properly, leakage due to loose pipe threads, pump connections, and oil drains can reduce pump efficiency.

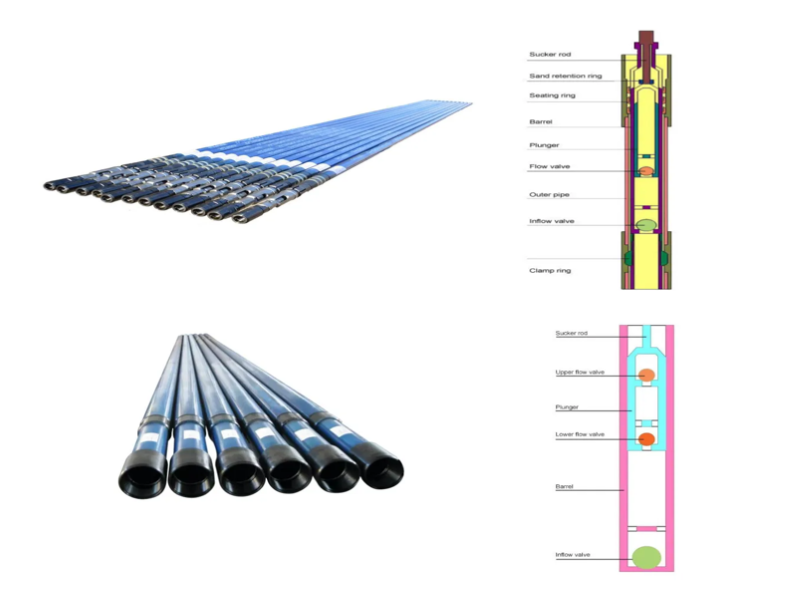

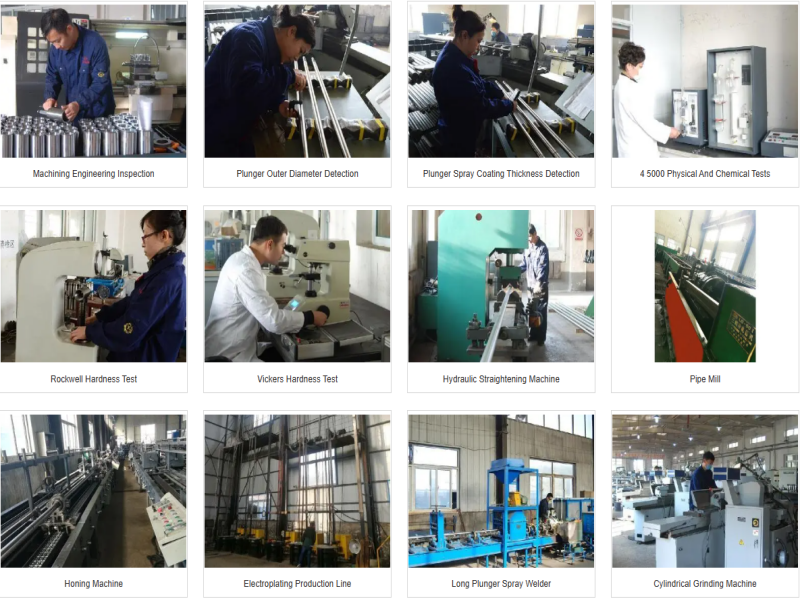

Dongsheng uses high-strength alloy steel and wear-resistant coating technology on key components such as the pump barrel and plunger to improve the wear resistance and corrosion resistance of the parts. This reduces energy loss caused by friction, allowing the pump to maintain high efficiency in high-sand and highly corrosive oil wells. Customers who are interested in purchasing our products are welcome to leave us a message at any time!

What is the process for purchasing Dongsheng products?

You can contact us by email, phone, or online, providing the rod pump model, specifications, quantity, and well conditions you require.

Our team will develop a product proposal based on your needs and provide a quote.

After you confirm the proposal, you will sign a purchase and sales contract, specifying specific terms such as price, payment method, and shipping method.

Processing and manufacturing will be carried out in accordance with the contract requirements, ensuring product quality meets API standards.

After production is completed, we will conduct rigorous inspections. Once qualified, we will arrange shipping and provide relevant documents such as bills of lading, packing lists, and commercial invoices.

After receiving the product, if you have any questions, please feel free to contact us. We will respond promptly and provide solutions to protect your rights.

Steps for running a tubing pump:

Run the tubing to the designed depth according to the operation plan.

Securely connect the pump barrel to the tubing to ensure a reliable seal.

Install the plunger assembly and sucker rods, connecting each rod to the wellhead.

Check the anti-surge distance and rod string length, and install the blowout preventer.

Conduct a trial run to check pump efficiency and sealing.

FAQ:

Q1: Are tubing pumps suitable for high-sand content wells?

A: Yes. Wear-resistant pump barrels and plungers can handle high-sand content conditions.

Q2: How long does it take to replace a tubing pump?

A: Because tubing must be tripped, this operation typically takes 1-2 days, depending on the well depth.

Q3: What is the service life?

A: Under normal well conditions, it can reach 4-6 years, with special wear-resistant models offering even longer.

If you are interested in purchasing our products, send me an email now to receive free selection advice and quotes, saving you time, worry, and money on oil well production.