08-31/2025

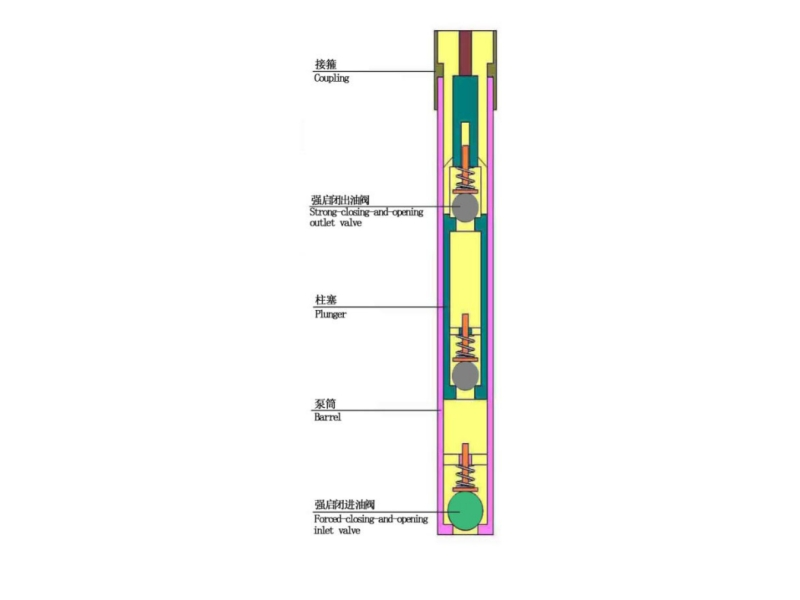

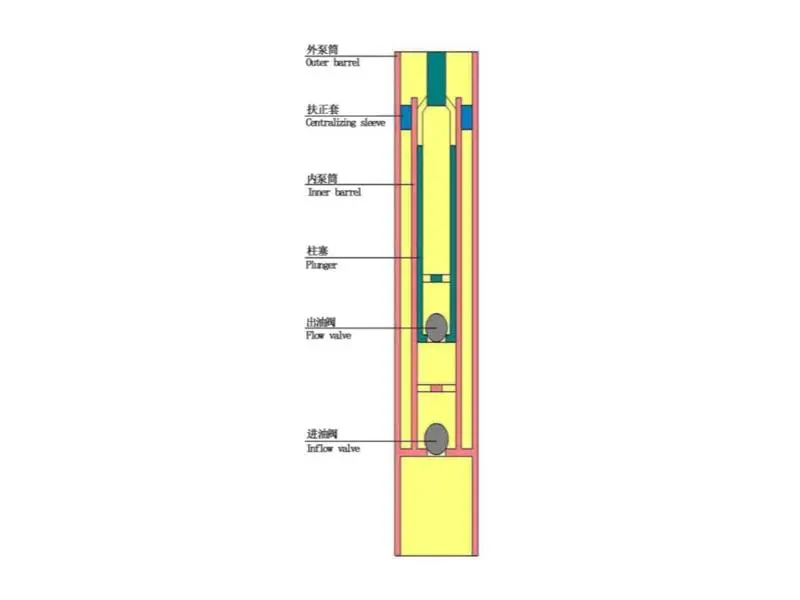

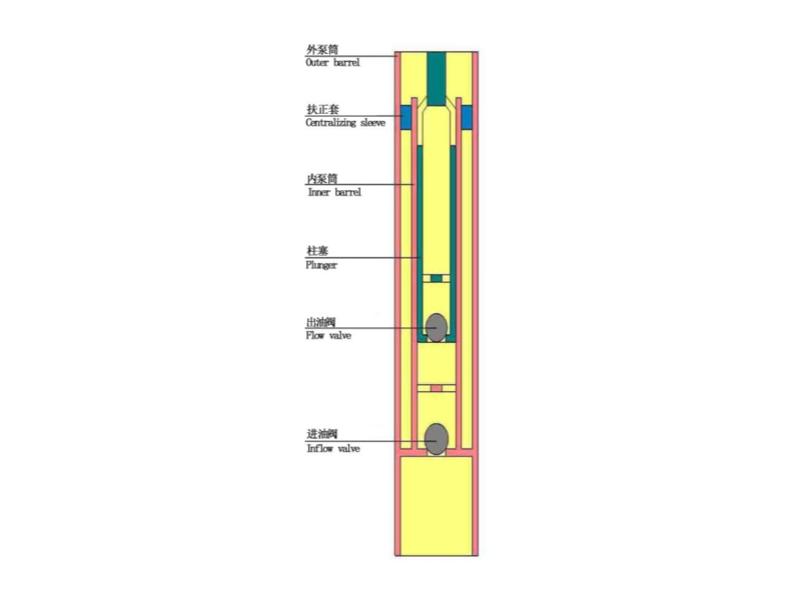

I. Overview of the Inclined Well Sucker Rod Pump:

During oilfield production, due to formation structure and specific conditions, oil well pumps operate in wells with a certain inclination. Using conventional pumps can cause valve closure lag, resulting in lower pump efficiency and increased production costs. To address this issue, we developed the Inclined Well Sucker Rod Pump, which addresses the issue of valve ball closure lag and improves pump efficiency.