10-20/2025

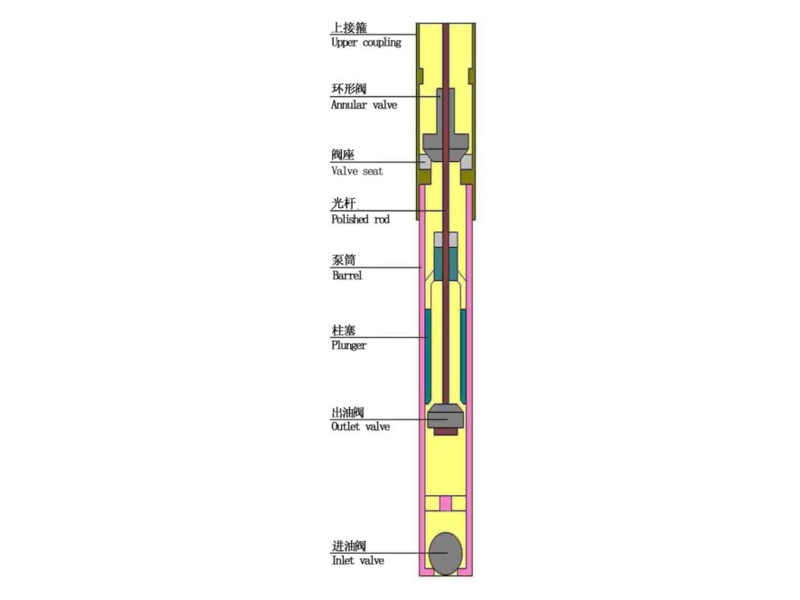

In the core equipment system of oil extraction, the stable operation of downhole sucker rod pump is the key to ensuring the continuous oil production of oil fields and improving the efficiency of mining. With the continuous expansion of oilfield development scenarios, from conventional shallow wells to deep wells, ultra-deep wells, from ordinary reservoirs to complex reservoirs with high sulfur content and high mineralization, the working conditions faced by downhole sucker rod pump are becoming more and more serious. As the core pressure bearing and sealing component of downhole sucker rod pump, the pump barrel is directly related to the overall performance, service life and operating stability of the equipment. It has become an important research direction in the industry to optimize the performance of downhole sucker rod pump.