09-02/2025

What is Gas Lock?

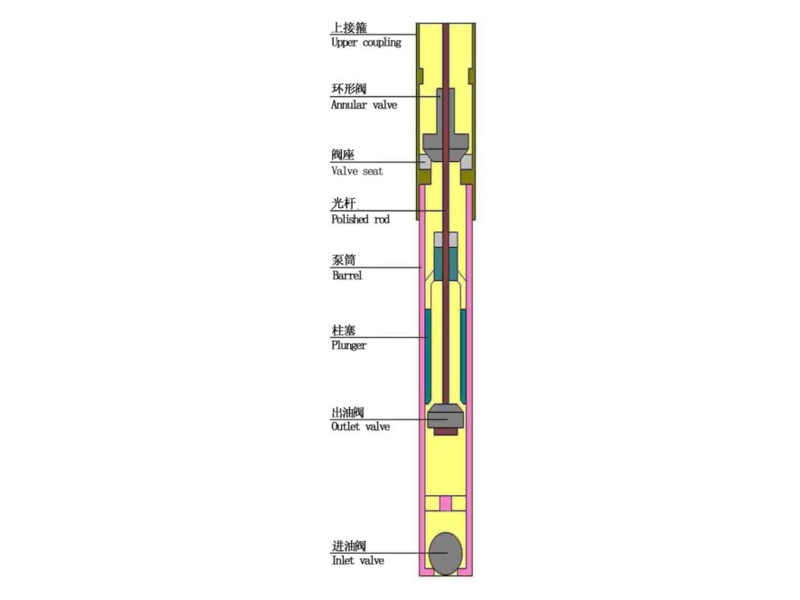

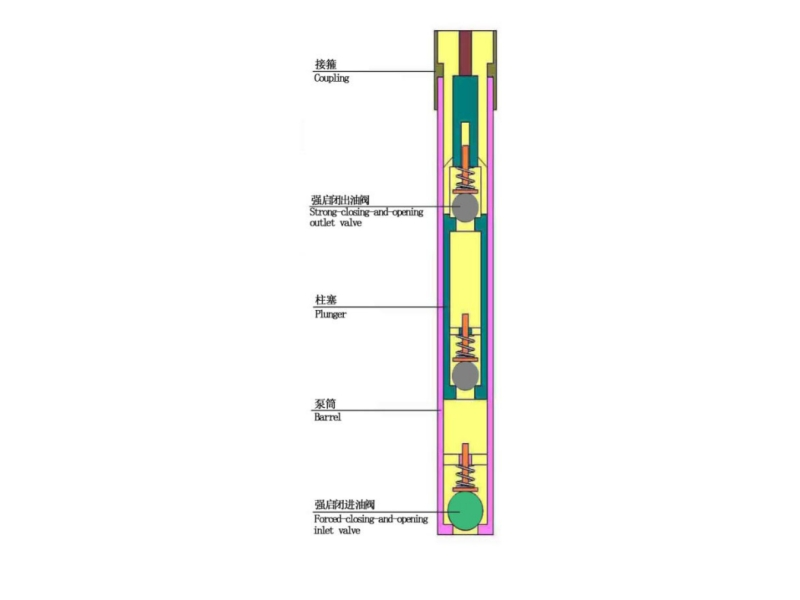

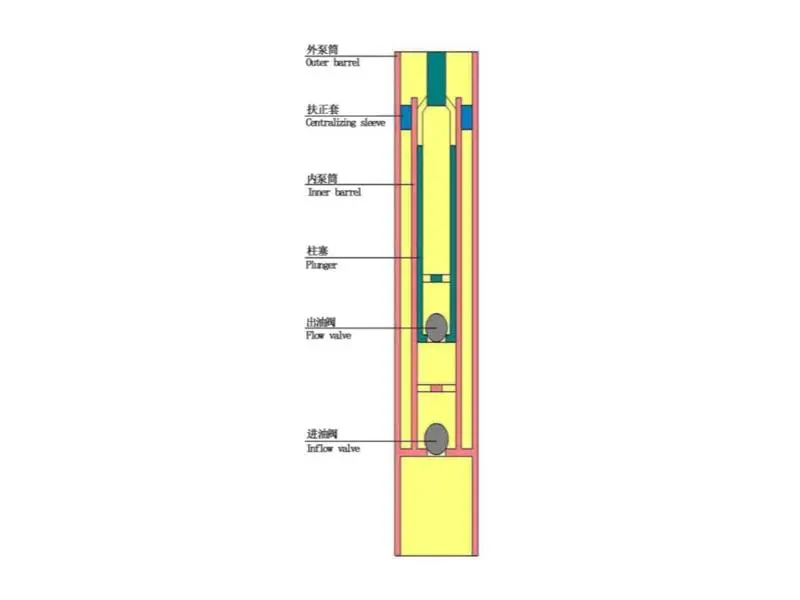

Some oil wells contain a high concentration of gas, which can enter the pump barrel through the fixed valve. If not promptly vented, the gas will gradually fill the space below the plunger in the pump barrel. As the plunger descends, the liquid in the tubing string acts on the traveling valve, exerting significant pressure. This prevents the traveling valve from opening, compressing the gas in the pump barrel below the plunger and preventing the flow of liquid above the plunger. As the plunger ascends, the compressed gas expands, exerting pressure on the fixed valve, preventing it from opening and preventing the pump from drawing liquid. This repetitive cycle of gas compression and expansion without any discharge is called gas lock.