In the demanding environments of modern oilfields, the difference between a productive well and a costly workover often comes down to one component: the subsurface pump. Selecting the right API 11AX rod pump requires more than just knowing the well depth; it requires a deep understanding of fluid dynamics, metallurgy, and mechanical stress.

| Pump depth,m | <900 | 900~1500 | 1500~2100 | >2100 | ||||||||||||||

| Pump type | Rod pump | Tubing Pump | Rod pump | Tubing Pump | Rod pump | Tubing Pump | Rod pump | Tubing Pump | ||||||||||

| Stationary Barrel Type | Traveling Barrel Type | Stationary Barrel Type | Traveling Barrel Type | Stationary Barrel Type | Traveling Barrel Type | Stationary Barrel Type | Traveling Barrel Type | |||||||||||

| Top Anchor | Bottom Anchor | Top Anchor | Bottom Anchor | Top Anchor | Bottom Anchor | Top Anchor | Bottom Anchor | |||||||||||

| Well conditions | Inclined well | a | c | - | a | a | c | a | a | a | c | - | a | c | c | - | b | |

| High fluid volume | - | - | b | a | b | b | a | a | a | c | a | a | c | a | b | b | ||

| Low fluid level | a | - | - | - | a | b | - | - | a | b | - | - | - | a | - | - | ||

| Vertical well | a | b | b | b | a | a | c | a | b | a | a | a | c | a | c | b | ||

| Medium sand content | a | - | c | c | a | - | b | c | a | - | c | b | - | a | - | c | ||

| High sand content | a | - | c | c | a | - | b | c | a | - | c | b | - | a | - | c | ||

| Salt | a | c | a | b | a | c | a | a | a | a | a | a | c | a | c | b | ||

| Hydrogen sulfide | a | b | b | b | c | a | b | a | - | b | a | a | c | a | c | b | ||

| Carbon dioxide | a | b | b | b | b | a | a | a | c | a | a | a | c | a | c | b | ||

| Medium sand content and moderate corrosion | a | c | c | c | a | b | b | b | b | a | a | b | c | a | - | c | ||

| High sand content and high corrosion | a | c | - | a | - | c | b | b | a | a | b | c | a | - | c | |||

| Viscosity | Below 400 mPa·s | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a | |

| Above 400 mPa·s | a | a | c | a | a | a | c | a | a | a | - | b | a | - | - | c | ||

| Note: a – Best practice; b – Widely used; c – Frequently used; “-” – Not recommended. | ||||||||||||||||||

1. The Core Selection Matrix: Depth and Pump Architecture

According to Dongsheng’s field-proven selection standards, the architecture of the pump (Tubing vs. Rod, Thin-wall vs. Heavy-wall) must align with the mechanical loads of the well.

Shallow Wells (<900m): For high-volume production at shallow depths, Dongsheng’s TH (Tubing Pump) or RWA/RWB (Thin-wall Rod Pump) are the most cost-effective choices.

Medium to Deep Wells (900m – 2,100m): As rod string weight increases, the RHB (Stationary Heavy-Wall Barrel, Bottom Anchor) becomes the industry standard. Its heavy-wall design prevents barrel "breathing," ensuring high volumetric efficiency.

Ultra-Deep Wells (>2100m): At these depths, we recommend the RHA (Top Anchor) or specialized RHB configurations. Top-anchored pumps are particularly effective in deep wells to prevent sand accumulation around the pump body.

2. Solving Harsh Condition Challenges

A "standard" pump often fails prematurely when faced with sand, gas, or corrosion. Dongsheng specializes in customizing pump parameters for these specific "pain points":

High Sand Content: For sandy wells, we recommend the RWT (Traveling Barrel) design. The movement of the barrel keeps the sand in suspension, preventing it from settling and "stucking" the pump.

Gaseous Wells: To combat "Gas Lock," Dongsheng adjusts the valve spacing and clearance fits. Our precision-honed barrels ensure that gas is compressed and discharged without locking the plunger.

Corrosive Environments (H2S/CO2): We offer specialized metallurgy. While API 11AX provides a baseline, Dongsheng goes further by offering Monel valves, Stainless Steel cages, and high-velocity oxygen fuel (HVOF) coatings to resist chemical attack.

3. Why Surface Treatment Matters

At our factory, we believe the longevity of a pump is determined by its skin. Dongsheng provides two primary plunger treatments for different wear profiles:

Chrome Plating: The gold standard for typical abrasive wear.

Spray Metal (Tungsten Carbide): Recommended for high-intensity friction environments where standard chrome might flake or wear prematurely.

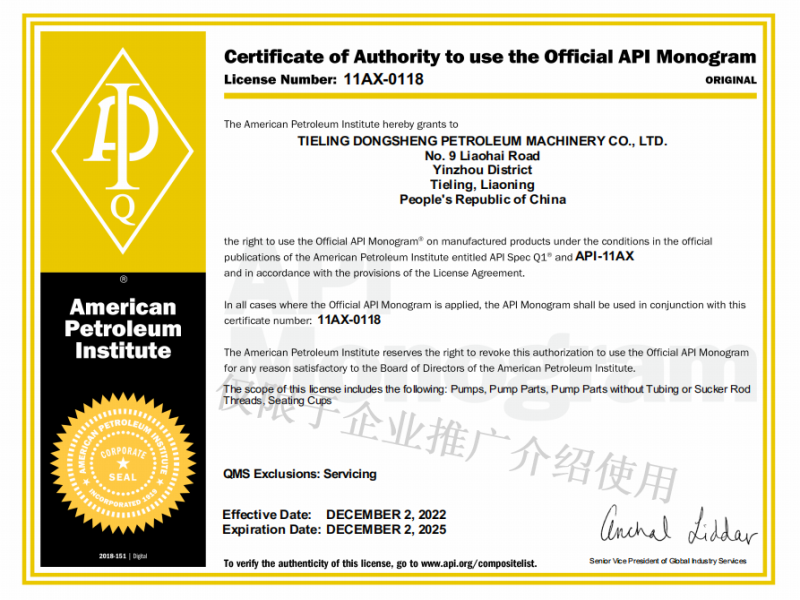

4. Proven Authority: Dongsheng’s Certifications and Global Footprint

Trust in the oilfield is built on certification. Dongsheng operates under a strict quality management system, evidenced by our API Spec 11AX Certification (Certificate No. 11AX-0081) and ISO 9001:2015 status.

These aren't just wall hangings—they represent our commitment to zero-defect manufacturing. Our pumps are currently operating in major global oil hubs, including:

North America (USA): Meeting the high-efficiency demands of shale production.

Central Asia (Kazakhstan): Solving problems in highly viscous and paraffin-heavy wells.

Middle East: Delivering reliability in high-temperature, high-pressure environments.

5. Case Study: Extending Pump Life in Sandy Wells

In a recent project in a high-sand oilfield, a client was experiencing pump failures every 4 months using standard tubing pumps. After analyzing their well data, Dongsheng’s engineers recommended a switch to a custom-clearance RWT Insert Rod Pump with a specialized sand-control valve.

The Result: The mean time between failures (MTBF) increased from 120 days to over 340 days, significantly reducing the client's OPEX.

6. Customizable Engineering by Dongsheng

Because Dongsheng is a direct factory, we don't just offer "off-the-shelf" products. Every parameter—from barrel length (up to 30ft) to plunger clearance (0.001" to 0.005")—can be customized to fit your specific BPD targets and SPM (Strokes Per Minute) settings.

Selecting the right API 11AX rod pump is a balance of science and field experience. By considering the interplay of depth, fluid type, and mechanical stress, you can drastically improve your oil recovery rates.

Need a technical evaluation for your current project?

Contact the Dongsheng engineering team. Provide us with your well depth and production goals, and we will provide a comprehensive pump selection report tailored to your assets.