Introduction: The High Stakes of Deep Well Recovery

I. Structural Fundamentals: How Installation Mechanics Dictate Profitability

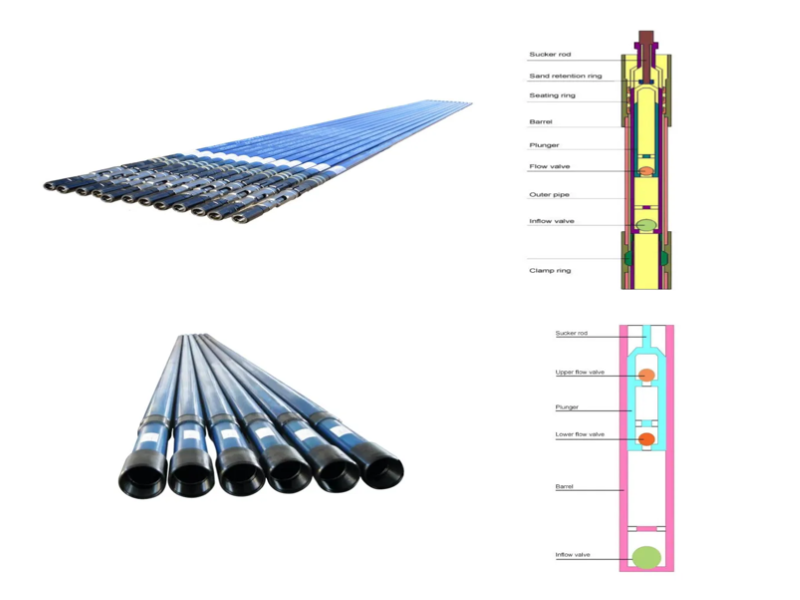

The Mechanic: Because the barrel diameter is nearly as large as the tubing ID, it allows for the maximum possible plunger size, leading to high displacement. The Deep Well Bottleneck: The barrel is "fixed." If the plunger wears out or a valve fails, the entire tubing string—thousands of meters of heavy steel—must be pulled to the surface. In a deep well environment, this necessitates a heavy-duty workover rig and days of non-productive time (NPT).

The Strategic Advantage: It is "mobile." When maintenance is required, the tubing string remains untouched in the borehole. Only the rod string is pulled, bringing the entire pump assembly to the surface.

The Dongsheng Edge: Our API 11AX Rod Pumps utilize advanced top or bottom anchor mechanisms (mechanical or cup-type). This ensures that even under the extreme pressures found in deep-borehole environments, the pump remains seated and sealed, a technical threshold many generic manufacturers fail to meet.

II. The Physics of the Deep: Overcoming Downhole Challenges

1. Alternating Loads and Sucker Rod Fatigue

2. Stroke Loss and Volumetric Efficiency

Deep wells result in significant elastic elongation of both the tubing and the rod string. Tubing Pumps, due to their heavier loads, suffer from greater "stroke loss." Rod Pumps, characterized by precision-engineered clearances and reduced loads, ensure that the surface stroke is more effectively transmitted to the downhole pump, maintaining higher volumetric efficiency in deep-lift scenarios.

III. Why Dongsheng (DS) Surpasses Competitors in the Global Market?

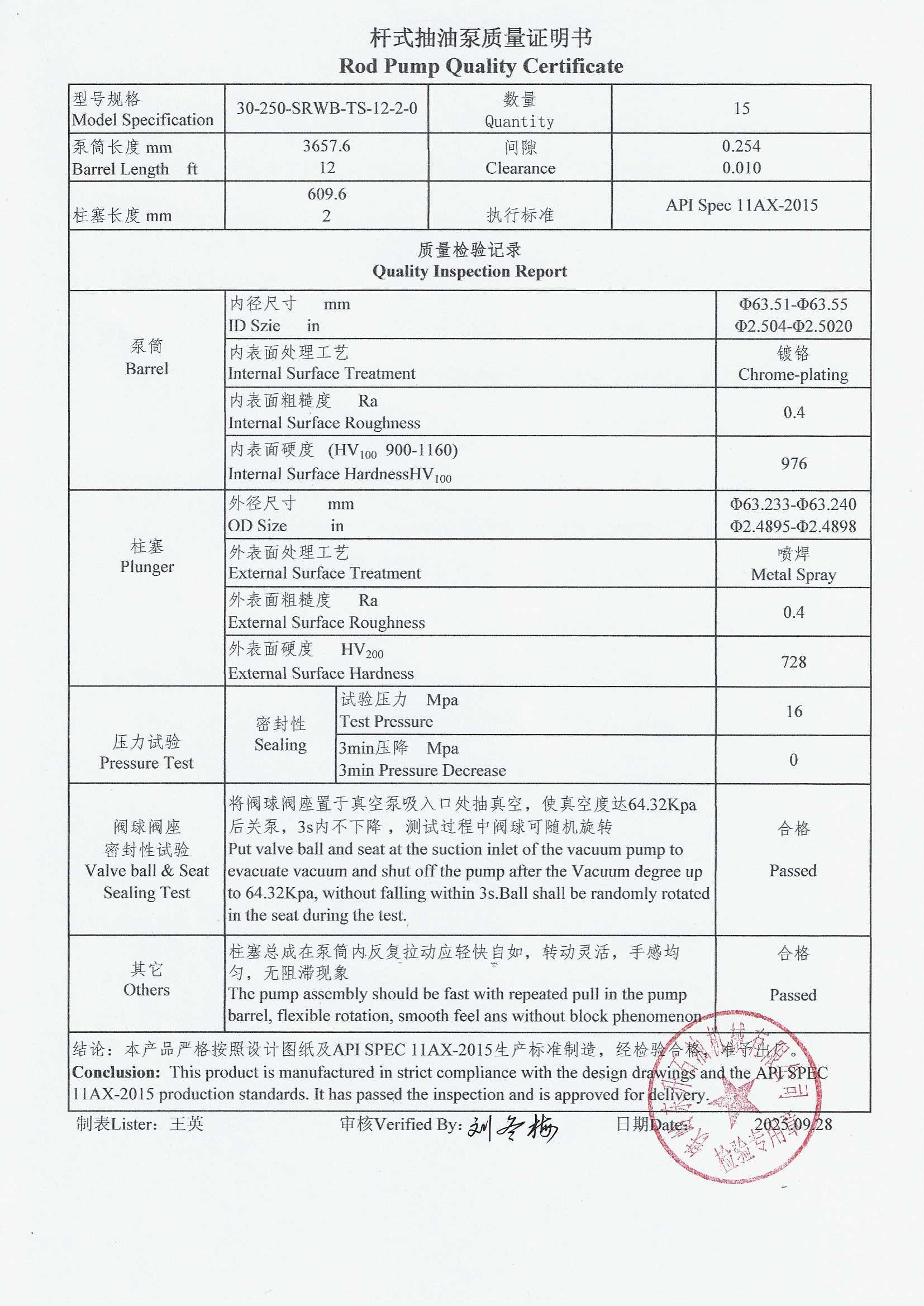

1. Master Class in Metallurgy and Surface Treatment

While competitors offer standard carbon steel, DS Rod Pump barrels undergo Ion Nitriding or Heavy-Duty Chrome Plating. Our plungers feature Nickel-based alloy spray welding, achieving a surface hardness of HRC 60+. This allows our pumps to operate in abrasive, sandy, or corrosive deep-well fluids for 200+ days longer than standard "off-the-shelf" products.

3. Custom "Survival Packages" for Harsh Wells

IV. The Economic Reality: OPEX vs. CAPEX

Workover Costs: A single deep-well Tubing Pump replacement typically costs 5 to 8 times more than a Rod Pump replacement due to rig time and labor.

Production Loss: Replacing a Rod Pump takes roughly 12 hours; a Tubing Pump can sideline a well for 3 to 5 days. Long-Term ROI: Continuous production for 24 months without a workover is the benchmark Dongsheng aims for in our deep-well installations.

V. Conclusion: Making the Right Call for Your Field

Choose a Tubing Pump if: Your well is shallower than 1,200 meters and you require massive fluid production where the tubing size is the limiting factor.

Your well depth exceeds 1,500 - 2,000 meters. You are operating in a remote location where workover rigs are expensive or scarce.

You prioritize the lowest Annual Operating Cost over the initial sticker price.