As global oilfields mature and production conditions become increasingly complex, selecting the right artificial lift system is decisive for controlling operating costs (OPEX) and minimizing downtime. While Electric Submersible Pumps (ESP) dominate high-volume offshore and deep-well applications, Oil Rod Pumps (Sucker Rod Pumps) remain the undisputed king of onshore and mature field economics.

Quick Comparison: The Technical Reality

| Feature | Oil Rod Pump | ESP Pump (Electric Submersible) |

| Working Principle | Positive Displacement (Reciprocating) | Dynamic (Centrifugal) |

| Best Application | Low-to-Medium Rate, Mature Fields | High Rate, High Water Cut, Deep Wells |

| Gas Handling | Excellent (with anchors/separators) | Poor (Prone to gas locking) |

| Solids/Sand Tolerance | High (Specialty metallurgy available) | Low (Erosion causes rapid failure) |

| Deviated Well Capability | Limited (Rod/Tubing wear risk) | Excellent (Follows wellbore path) |

| Power Consumption | Low (High systemic efficiency) | High (Significant power bills) |

| Workover Complexity | Low (Surface repair often possible) | High (Requires full rig to pull tubing) |

7 Reasons Why Operators Choose Oil Rod Pumps

1. Superior Economics in Declining Reservoirs

Volumetric Efficiency: Rod pumps are positive-displacement pumps. They lift exactly what enters the barrel. Adjustability: As the well declines, operators can simply slow down the pumping unit (SPM) or shorten the stroke length at the surface. There is no need for an expensive workover to resize the pump.

2. Resilience to Gas Interference

Separation: Effective downhole gas separators and anchors can be easily integrated. Valve Design: Modern rod pumps utilize specialized traveling valves and minimal clearance designs to compress gas and prevent gas locking. Intermittent Capability: If a well becomes gassy or pumps off, a rod pump can be set to run intermittently (e.g., via Pump-Off Controllers), whereas cycling an ESP frequently destroys the motor.

3. Handling Sand and Solids

Design Flexibility: Rod pumps can be equipped with hard-faced spray metal plungers, ceramic barrels, and specialty filter cages. Tolerance: Because the pump moves slower, abrasive wear is significantly reduced compared to high-velocity centrifugal systems.

4. Lower Total Cost of Ownership (TCO)

Power: Rod pumps generally consume significantly less electricity for the same lift in low-rate wells. Repair: Troubleshooting often happens at the surface. A worn valve or parted rod can often be fixed with a standard service truck, whereas an ESP failure requires a full workover rig to pull the entire completion string.

5. Surface-Based Diagnostics and Troubleshooting

Dynamometer Analysis: Operators can diagnose downhole conditions (leaking valves, tubing movement, fluid pound) using a surface dynamometer card. Predictive Maintenance: Issues can often be identified before failure occurs, allowing for planned maintenance rather than emergency shutdowns.

6. Longer Run Life in Harsh Conditions

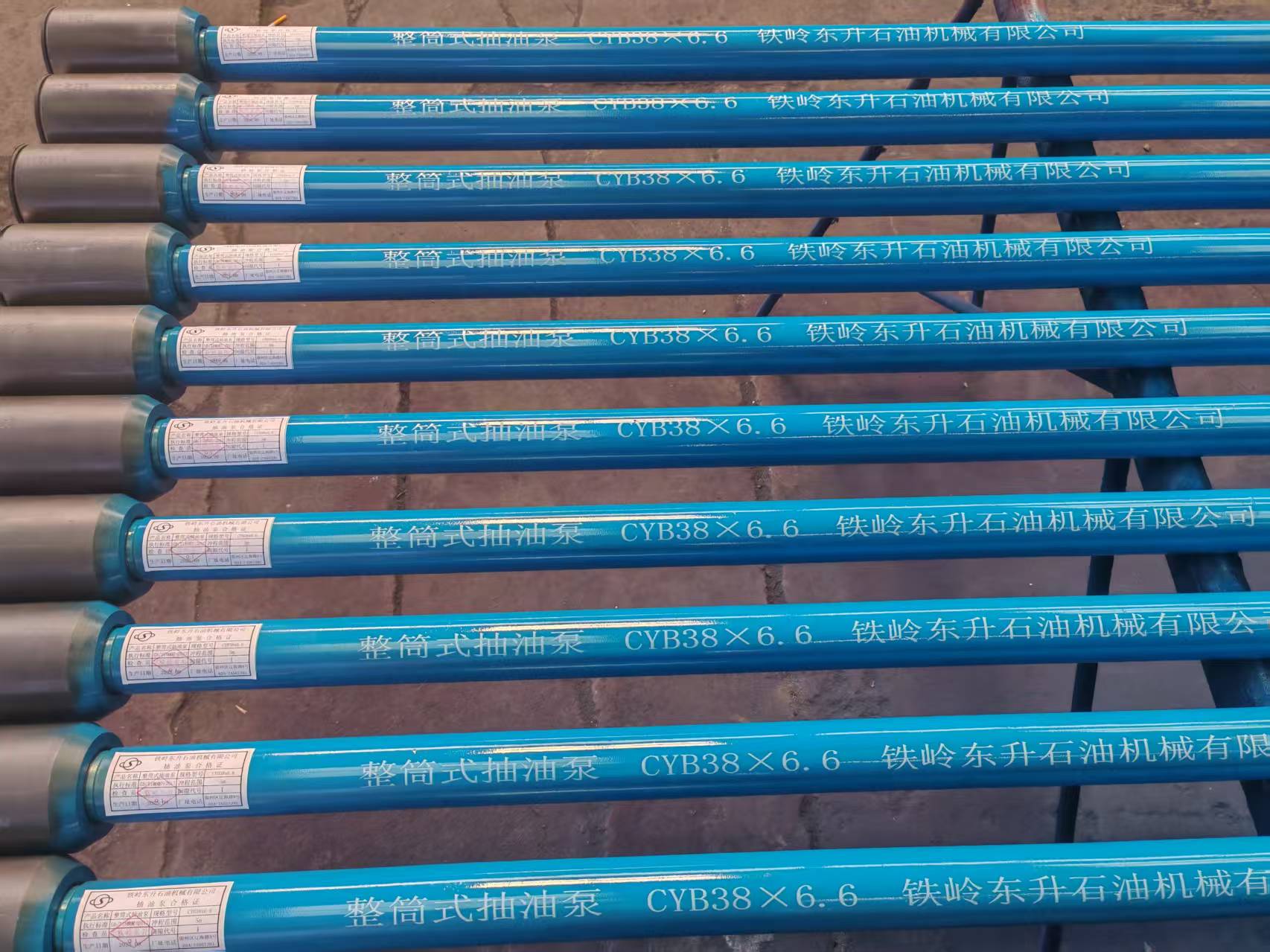

Simplicity: There are no sensitive electronics downhole. Material Selection: By adhering to API 11AX standards, buyers can select varied metallurgy (Chrome-plated, Stainless Steel, Brass) to specifically combat H2S or CO2 corrosion, extending run times to years rather than months.

7. Residual Value

When NOT to Choose a Rod Pump

Production Rates are Very High: Rod pumps generally max out around 3,000–4,000 BPD (depending on depth). Well Deviation is Extreme: In highly deviated or horizontal wells (high Dogleg Severity), the friction between sucker rods and tubing causes rapid wear. Depth: For ultra-deep wells (>10,000 ft), the rod string weight becomes a limiting factor.

Conclusion: A Strategic Return to Reliability