The 2025 Expert Guide: From Engineering Logic to Field Realities.

Authoritative Guide for Operators, Engineers, and Procurement Teams.

Who is this guide for?

This guide is designed for:

Oilfield Operators who want to reduce pump failures and stabilize production.

Artificial Lift Engineers who require deeper insight into material selection, tolerances, and downhole wear mechanisms.

Procurement Teams looking to make smarter sourcing decisions and avoid hidden lifecycle costs.

Maintenance Supervisors aiming to implement predictive maintenance instead of reactive repairs.

Energy Service Companies that need up-to-date 2025 engineering standards and field-proven practices.

1. Oil Rod Pump Failure Causes: Why Service Life Varies

A high-quality pump cannot overcome a hostile environment alone. Service life is determined by the "Weakest Link Principle." The three pillars are:

The Pump Quality (Metallurgy, Precision)

The Downhole Environment (Corrosion, Sand, Gas)

The Human Factor (Installation, Settings, Maintenance)

Pro Tip: Field data suggests that 40% of failures are attributed to downhole conditions, 30% to operational errors, and only 30% to actual pump manufacturing defects.

2. 2025 Oil Rod Pump Material Selection Guide

Cheap materials are the most expensive choice in the long run.

2.1 Plunger & Barrel Matching (The Friction Pair)

The interaction between the plunger and barrel defines the pump's seal and lifespan.

Standard Service: Hardened steel barrels with spray metal plungers.

Abrasive/Sand Service: Requires Ceramic or Carbide coatings.

Hardness Hierarchy: The plunger surface should typically be harder than the barrel (e.g., Plunger 50-60 HRC vs. Barrel ~30 HRC for standard pumps) to ensure wear is controlled.

2.2 Corrosion Resistance

In H₂S (sour) or CO₂ (sweet) environments, standard carbon steel will pit and crack within weeks.

Solution: Use Brass, Monel, or Stainless Steel components.

2025 Trend: Advanced Ni-P (Nickel-Phosphorus) coatings are becoming standard for cost-effective corrosion resistance.

3. How Downhole Conditions Affect Rod Pump Longevity

You cannot change the reservoir, but you can adapt the pump.

3.1 Sand and Solids

Sand acts like sandpaper between the plunger and barrel.

Impact: Scratched barrels lead to "slippage" (fluid leaking back down), reducing efficiency and forcing the pump to work harder.

Mitigation: Use a Sand Filter intake or select a pump with tighter clearances designed to wipe sand away rather than trap it.

3.2 Gas Interference

High Gas-Liquid Ratio (GLR) causes "Gas Lock."

The Damage: The fluid pound (shock) from gas lock acts like a hammer blow to the valves and rod string on every stroke.

Mitigation: Install a gas anchor/separator and use pumps with small traveling valve cages to reduce unswept volume.

3.3 Temperature

In thermal recovery (SAGD/CSS), temperatures can exceed 250°C (480°F).

The Risk: Metal expansion can cause the plunger to seize inside the barrel if the clearance is too tight.

Action: Specify "Class 3" fits with larger clearances for thermal wells.

4. Oil Rod Pump Manufacturing Precision and Its Impact on Service Lifer

Not all API pumps are created equal.

Tolerances: The gap between plunger and barrel is often measured in thousandths of an inch. A deviation of just 0.001" can result in either seizure (too tight) or massive leakage (too loose).

Concentricity: If the threads are not perfectly aligned with the barrel, the pump will sit at an angle, causing severe one-sided wear (elliptical wear).

Buyer’s Note: Always ask your supplier for their Quality Control (QC) reports regarding straightness and surface finish (Ra values).

5. How Operational Practices Influence Rod Pump Life

The best pump in the world will fail if installed poorly.

5.1 The "Pump-Off" Problem

Running the pump when the wellbore is empty is the #1 cause of premature failure.

Effect: No fluid means no lubrication and no cooling. The friction heat destroys the barrel surface instantly.

2025 Solution: Use AI-driven Pump-Off Controllers (POC) that automatically slow down or stop the pump when fluid levels drop, detecting the issue via dynamometer card analysis.

5.2 Setting Depth & Spacing

Spacing: If the pump hits the top or bottom ("tagging"), the physical impact will shatter valves and bend rods.

Intake Placement: Placing the intake above the perforations helps separate gas naturally, extending life.

5.3 Stroke Speed (SPM)

Speed kills. High strokes per minute (SPM) generate exponential friction wear.

Rule of Thumb: It is better to run a larger pump at a slower speed than a small pump at high speed.

6. Rod Pump Failure Troubleshooting Guide (2025 Updated Matrix)

| Oil Rod Pumps | Likely Cause | Solution for Next Pump |

| Vertical Scratches on Plunger | Sand/Solids Abrasion | Upgrade to Carbide coating; Check sand screens. |

| Pitting / Rusty Surface | Corrosion (H₂S/CO₂) | Switch to Stainless Steel or Monel; Use Chemical inhibitors. |

| Valves/Balls Shattered | Fluid Pound (Gas/Pump-off) | Install Gas Separator; Adjust Pump-Off Controller settings. |

| One-sided Wear | Misalignment / Deviated Well | Use Guide Rods; Check tubing straightness. |

| Seized Plunger | Scale or Thermal Expansion | Increase Plunger-Barrel clearance; Use scale inhibitors. |

7. How to Extend Oil Rod Pump Service Life in 2025

Modern maintenance is predictive, not reactive.

Chemical Management: Continuous injection of corrosion and scale inhibitors can double pump life in harsh wells.

Dynamometer Analysis: Regular "dyno cards" act as an X-ray for the pump, revealing leaking valves or barrel wear before catastrophic failure occurs.

Proper Transport: Never overlook how pumps are handled. A dropped pump or a bent barrel during transport ensures failure before installation.

Conclusion: How to Maximize ROI?

The service life of an oil rod pump is a balance between cost and performance.

For a low-production, shallow well, a standard API pump is sufficient.

For a deep, corrosive, sandy well, investing 30% more in premium materials (Spray Metal, Carbide) can yield 200% longer run times.

The takeaway for 2025: Stop treating pumps as disposable commodities. Treat them as precision instruments that require the right environment, the right settings, and the right monitoring to perform.

About Our Company – Tieling Dongsheng Petroleum Machinery Co., Ltd.

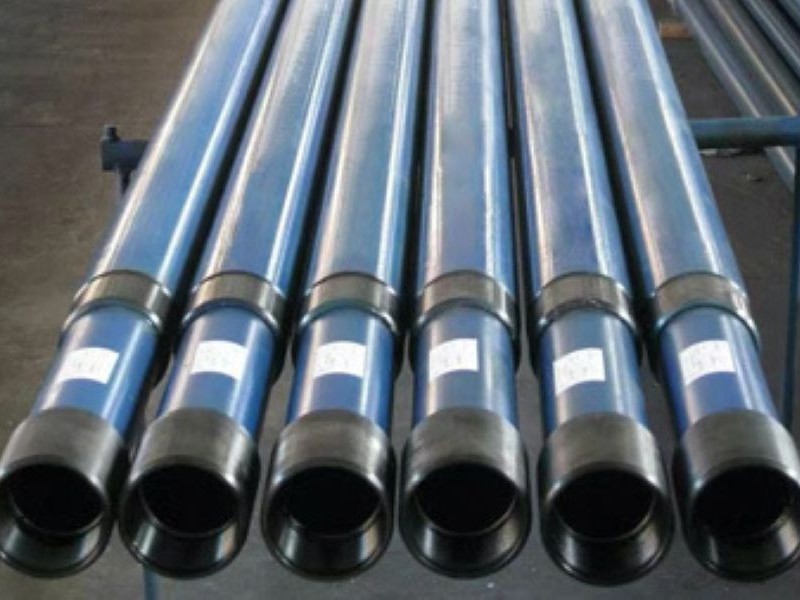

Founded in 2000, Tieling Dongsheng Petroleum Machinery Co., Ltd. is a vertically integrated manufacturer of API-standard sucker rod pumps, specialty rod pumps, plungers, barrels, and other downhole components, serving major domestic oilfields as well as international operators.

Covering approximately 20,000 m² of production space with 116 employees, including 20 engineers, Dongsheng has an annual production capacity of over 20,000 pumps and thousands of full-tube pump sets, meeting both domestic and overseas demand.

The company operates under a documented ISO 9001 quality management system, holds API 11AX licensing, and maintains ISO 14001 and ISO 45001 certifications, with full measurement and inspection capabilities to ensure traceability, process control, and consistent product quality.

Dongsheng's factory is equipped with advanced machining centers, hardness and metallurgical testing instruments, electroplating and spray-coating lines, honing and straightening equipment, and other precision inspection tools, supporting the production of wear-resistant and corrosion-resistant components tailored to challenging well conditions.

With a growing portfolio of exported projects and satisfied clients across regions, including the Middle East, North America, and Southeast Asia, Dongsheng continues to provide reliable, high-performance pumping solutions backed by engineering expertise and field-proven practices.