Recently, we successfully delivered a batch of high-quality rod pump barrels to the domestic Daqing oilfield. We follow strict production technology and reliable packaging and transportation plans to deliver the products in good condition and on schedule to ensure the stable supply of oilfield mining equipment.

Project background:

As a leading domestic oil production base, Daqing Oilfield has long assumed the heavy responsibility of ensuring the country's energy supply. In daily mining and equipment maintenance operations, there are strict requirements for the stability and adaptability of underground core equipment. As a key component of the pumping system, rod pump barrels, the performance of rod pump barrels directly affects the mining efficiency and operation continuity. Based on domestic industry standards and mature experience accumulated in the field of rod pump barrels R&D and production, Dongsheng Petroleum has successfully reached a cooperation with Daqing Oilfield after multiple rounds of technical communication and demand matching. The rod pump barrels supplied are mainly used for daily production operations and equipment rotation maintenance in multiple main oil production blocks to help the oilfield ensure the progress of mining.

Characteristics of oilfield working conditions:

The mining area of Daqing oilfield is concentrated in the Songliao Basin. The geology and oil quality characteristics put forward clear requirements for the adaptation of rod pump barrels: in terms of geological structure, the sand and mudstone interlayer is the main one, and the formation pressure is generally stable, but the formation of some mining blocks contains trace impurities, which can easily cause wear on the inner wall of rod pump barrels during long-term operations; In terms of oil quality, it is a conventional crude oil with low viscosity and low sulfur content. Although the overall mining conditions are friendly, the sealing and pressure stability of rod pump barrels are required to be high-it is necessary to ensure that in long-term pumping operations, it will not be due to The failure of the seal leads to the leakage of crude oil, or the mining efficiency is affected by insufficient pressure, which has also become the core consideration of rod pump barrels product adaptation design.

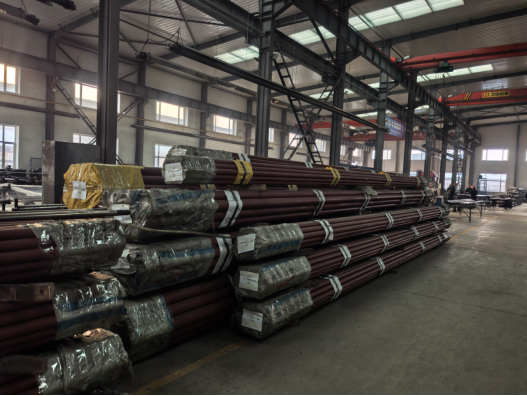

Logistics, transportation and packaging:

As the core operation and maintenance component of the oilfield, rod pump barrels, timely supply is the key to ensuring the progress of mining. In the logistics and transportation link, we give priority to domestic dedicated line logistics. Relying on the long-term cooperative logistics team, we formulate a direct transportation plan for the transportation characteristics of rod pump barrels to reduce the potential impact of the transit link and ensure the rapid delivery of goods. On the packaging, combined with the precision structure of rod pump barrels, it is reinforced so that rod pump barrels can be moisture-proof, shock-proof, and anti-collision during transportation, so as to ensure that the products are kept intact when they arrive and delivered on time.