What is downhole sucker rod pump and how does it work?

Downhole sucker rod pump generally refers to a plunger-type oil pump driven by the reciprocating movement of the sucker rod up and down. It is the key underground equipment of the rod pumping system. It is mainly composed of four parts: pump cylinder, plunger, fixed valve and swimming valve. When working, the ground pumping unit drives the plunger up and down through the pumping rod. During the upper stroke, the sucker rod column pulls the plunger upward, and the swimming valve is closed by the pressure of the liquid column in the tubing. The volume of the pump chamber under the plunger increases and the pressure decreases. The fixed valve is opened and the crude oil is sucked into the pump. At the same time, the liquid in the tubing is discharged to the ground; during the lower stroke, the sucker rod column drives the plunger to move downwards, the pressure in the pump increases, and the fixed valve is closed. When the pressure is greater than the liquid pressure above the plunger, the swimming valve is jammed open, and the liquid under the plunger enters the upper part of the plunger to realize the pump's discharge into the tubing. This reciprocating process continues to circulate, so that the crude oil underground is continuously pumped to the ground.

Which mining scenarios is downhole sucker rod pump suitable for?

Downhole sucker rod pump is widely used in the field of oil extraction. In conventional on-land oilfield mining, the pumping can be directly adapted to the existing pumping unit equipment without the need to transform the wellhead device. It is suitable for oil wells with declining formation energy, low original energy or thick oil, and can achieve continuous oil recovery through mechanical power. For medium and shallow oil wells, due to the advantages of simple structure and easy maintenance of downhole sucker rod pump, it usually becomes the preferred oil production equipment for medium and shallow oil wells. It can also play an important role in some small boreholes, multi-layer completions, and high-temperature and high-viscosity crude oil mining scenarios.

What are the advantages of downhole sucker rod pump over other oil production equipment?

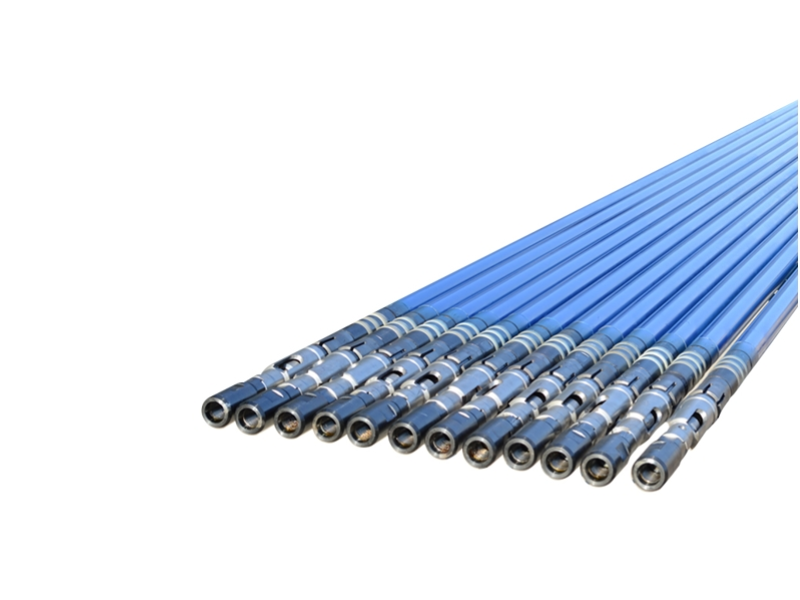

1. The structure of downhole sucker rod pump is simple, and it is mainly composed of three parts: ground pumping unit, intermediate pumping rod and column, and underground pumping pump. This makes equipment manufacturing, installation and maintenance relatively easy, greatly reducing the technical difficulty and maintenance costs.

2. Downhole sucker rod pump has strong adaptability to oil recovery and can be applied to a variety of different types of reservoirs, whether it is a reservoir with low formation pressure or a higher one, or a complex reservoir such as heavy oil and low permeability reservoirs, it can carry out oil recovery work better.

3. The downhole sucker rod pump has a relatively long service life. Under normal maintenance, it can operate stably for a long time, providing a guarantee for the long-term stable production of oil fields. In addition, in medium and low-yield wells, rod pumps can maintain good working efficiency.

What problems does downhole sucker rod pump face in use?

Although downhole sucker rod pump is widely used, it also faces some challenges in actual use. In curved or oblique wells, the inner wall of the sucker rod and the tubing is prone to excessive friction, which will not only accelerate the wear of the sucker rod, but may also cause the sucker rod to break, affecting the normal progress of oil production operations. At the same time, rod pumps are more sensitive to solids. When the produced liquid contains more solid impurities such as sand particles, it is easy to cause problems such as pump valve wear and pump jamming, reducing the service life and working efficiency of the pump. In gas-containing oil wells, the presence of gas will reduce the degree of filling of the pump, resulting in reduced pump efficiency. In addition, due to the limited carrying capacity of the sucker rod, the mining depth of the rod pump is limited to a certain extent. When operating offshore, its equipment is relatively large and there are certain limitations.

How will downhole sucker rod pump develop in the future?

As oilfield development enters the middle and late stages, improving recovery, reducing production costs, energy saving and emission reduction have become important goals, and downhole sucker rod pump is also constantly developing and improving. On the one hand, by improving the structural design of the pump, such as improving the shape and size of the pump cylinder and plunger, and optimizing the flow channel design, the efficiency and reliability of the pump can be improved, and the phenomenon of internal and external leakage can be reduced. On the other hand, the application of new materials will improve the performance of downhole sucker rod pump. For example, the use of high-strength, corrosion-resistant and wear-resistant materials to manufacture sucker rods and pump bodies can effectively extend the service life of equipment and enhance its adaptability in complex environments. In addition, intelligent technology will gradually be integrated into the downhole sucker rod pump system. Through the installation of downhole sensors, the working status of the pump will be monitored in real time, and data such as remote monitoring power diagrams will be used to realize the precise control of the downhole sucker rod pump and further improve the efficiency of oil recovery.

Reference materials:

Full analysis of the oil pumping system of the rod pump: from the principle of the device to the key technology of efficient oil recovery.

Rod pump pumping, performance and selection-SDN blog.

Recommended practices for the maintenance and use of underground pumps, Fourth edition.