At present, the development of global oil and gas resources is gradually turning to the field of difficult to recover reserves, of which the proportion of heavy oil resources is increasing year by year. However, complex well conditions such as high temperature, high pressure, and high viscosity have become key bottlenecks restricting the efficient extraction of heavy oil. In this context, thermal recovery sucker rod pump, with its unique technical advantages, has gradually become the core equipment for solving complex well mining problems. Its precise positioning of adapted well conditions provides important support for improving the efficiency of oilfield development.

Table of contents:

High viscosity oil thermal recovery well

High temperature and high pressure well

Large slope directional well

Reference materials

According to industry statistics, the proportion of thermal recovery sucker rod pump applications in complex wells has continued to rise in recent years, and the operation success rate under specific adapted well conditions has steadily reached 100%. It has become the preferred equipment for oilfield companies to ensure mining efficiency and reduce operating costs.

1. High viscosity oil thermal recovery well:

Due to the special molecular structure of heavy oil resources, the viscosity is extremely high and the fluidity is poor at room temperature. It is difficult for conventional mining equipment to achieve effective lifting. Therefore, it is necessary to reduce the viscosity through thermal mining techniques such as steam injection before starting oil pumping operations. This process puts forward dual requirements for equipment: It must not only withstand the high temperature of the steam injection stage, but also accurately control the fluid flow in the pumping stage. Thermal recovery sucker rod pump is a special equipment developed for this core requirement.

Integrated design to simplify the operation process:

The core advantage of thermal recovery sucker rod pump lies in the integrated design, which can realize the steam injection and oil pumping operations without moving the pipe column, without frequent lifting and lowering of the pipe column. This design not only reduces the cumbersome operation links, but also avoids the interference of multiple operations on the well environment, and improves the mining efficiency from the process.

Accurate monitoring to ensure mining effect:

In practical applications, thermal recovery sucker rod pump can accurately solve the problems of temperature and pressure measurement in the process of heavy oil thermal recovery, and monitor the vapor absorption profile in real time.Through the real-time data obtained, the oilfield can adjust the subsequent mining parameters in a timely manner to provide data support for efficient mining, thereby significantly improving the pumping efficiency.

2. High temperature and high pressure well:

With the advancement of oil and gas exploration and development to deep-sea, offshore and other fields, the number of high-temperature and high-pressure wells has been increasing. This kind of well condition puts forward extremely high requirements for the temperature and pressure resistance of the equipment. Due to the complex geological conditions of deep and heavy oil wells on land, the pressure is generally maintained at a high level. Traditional equipment is prone to sealing failure, structural deformation and other problems in such environments, which seriously affect the safety and efficiency of operations, and thermal recovery sucker rod pump has fundamentally solved this problem through technological innovation.

Material upgrade to improve temperature and pressure resistance:

In terms of material selection, the core components of thermal recovery sucker rod pump are made of high temperature resistant alloy materials, which can maintain stable mechanical properties in extreme high temperature environments; The sealing structure adopts multi layer composite sealing technology, which can effectively resist the impact of high pressure fluids, prevent leakage accidents, and lay the foundation for the safe operation of equipment under extreme working conditions.

3. Large slope directional well:

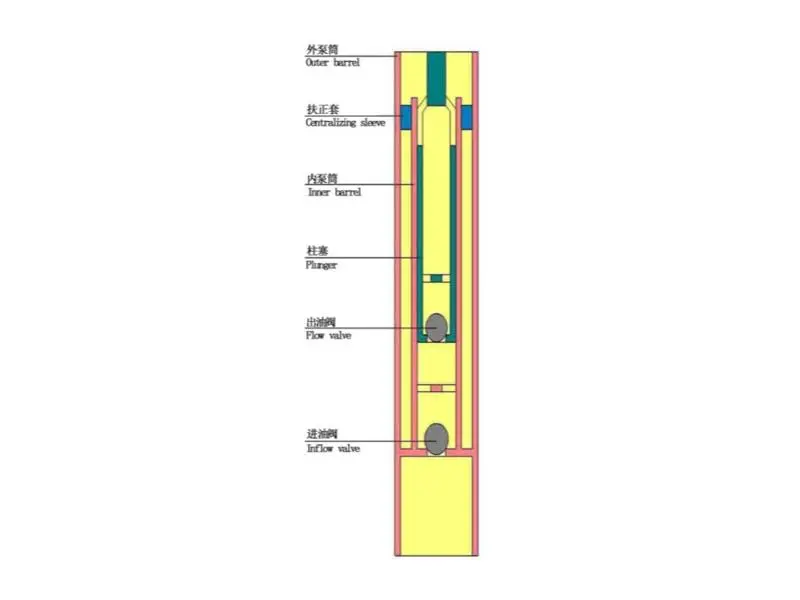

Due to the special structure of the well body, the well slope angle of large-slope directional wells generally exceeds 42°, and the well slope of some horizontal wells even reaches more than 60°. Under such well conditions, conventional rod pumps are prone to partial wear due to the increase in the contact area of the rod and tube and uneven force, which leads to shortened equipment life and reduced pump efficiency. In response to this pain point, thermal recovery sucker rod pump has made changes in both structural design and accessory improvement, forming an efficient solution for large slope wells.

Improve the righting design and reduce partial wear:

Thermal recovery sucker rod pump accurately calculates the spacing of the centralizers and arranges the centralizers rationally, which reduces the direct contact between the rods and pipes, reduces the probability of partial wear from the root cause, extends the service life of the equipment, and reduces the number of pump inspections and workovers.

Improve the valve set to ensure fluid flow:

In terms of valve set design, thermal recovery sucker rod pump improves the layout of the valve set, so that the fluid flows smoothly in the inclined well section, avoiding the loss of pump efficiency caused by poor flow channel, and further improving the lifting efficiency.

High temperature resistant materials adapt to changes in working conditions:

In addition, the high temperature resistant sealing material used can adapt to temperature fluctuations in the thermal mining process, prevent the sealing performance from degrading due to temperature changes, ensure the long-term stable operation of the equipment under complex working conditions, and provide a practical solution for the efficient development of large-slope directional wells.

4. Economic advantage:

In addition to its adaptability advantages in different well conditions, thermal recovery sucker rod pump's economic performance is also outstanding, which has become an important support for cost reduction and efficiency enhancement in oil fields.

From the point of view of operating costs, its integrated design reduces cumbersome operating links such as lifting and lowering pipe columns, and greatly reduces the frequency of inspection and workover of pumps. Compared with ordinary dual-purpose injection and pumping pumps, it can save a lot of workover costs; From the point of view of operating efficiency, the integrated injection and mining process supporting thermal recovery sucker rod pump can significantly shorten the single round of operation time and improve the overall mining efficiency.

Industry experts analyzed and pointed out that the technological upgrade and adaptability improvement of thermal recovery sucker rod pump not only solved the technical problems in complex well mining, but also promoted the transformation of the heavy oil thermal mining industry from “feasible mining” to “efficient and economical mining”, providing important technical support for the development of difficult to recover oil and gas resources around the world.In the future, with the further iteration of technology, the application scope and market potential of thermal recovery sucker rod pump will continue to expand.

Reference materials:

[1] International Energy Agency (IEA) "2024 Global Heavy Oil Development Report"

[2] China National Petroleum Corporation (CNPC) "Technical Manual for Thermal Recovery Lifting Equipment (2024 Edition)"

[3] National Petroleum and Natural Gas Pipeline Network Group "Test Standard for Temperature and Pressure Resistance of Oil Drilling and Production Equipment (GB/T 40278-2024)"

[4] The third issue of the journal "Petroleum Machinery" in 2024, "Thermal recovery sucker rod pump anti-bias wear technology optimization for Large slope wells"

[5] "Oil and Gas Field Development Project" 2024 Issue 1 "Global Thermal Mining Equipment Technology Development Trends"