07-24/2025

In the previous article, we talked about what is the difference between api sucker rod pump and submersible electric pump?

If you want to know more about the related content, you can click the link to visit!

Overview of API tubing pump:

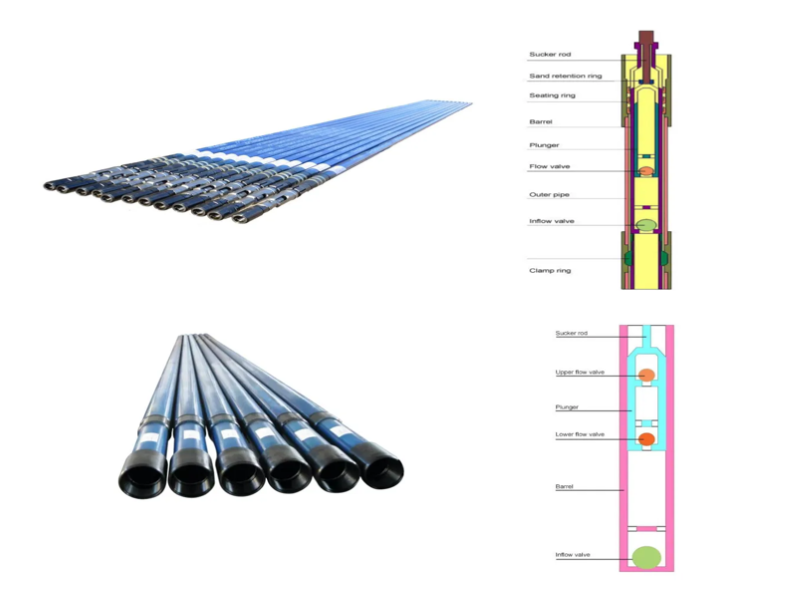

1. Composition of oil pump:

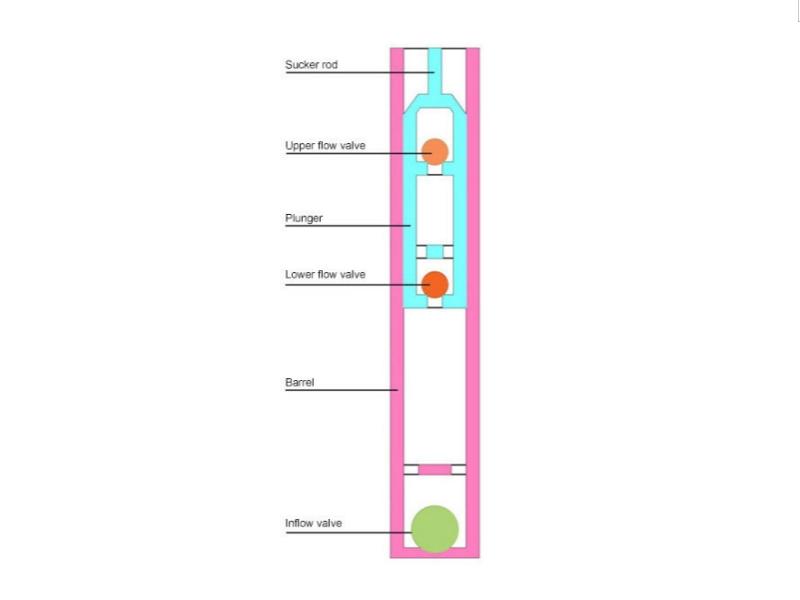

The pump barrel assembly of API tubing pump is directly connected to the lower end of the oil pipe, and the plunger goes into the pump barrel with the sucker rod. API tubing pump consists of two parts: pump barrel assembly and plunger assembly. The pump consists of a pump barrel, a fixed valve and a hollow plunger with a floating valve.

2. Working principle:

During the pumping process, the plunger reciprocates up and down in the pump barrel with the movement of the sucker rod. During the upstroke, the floating valve ball on the plunger is closed, the fixed valve ball is opened, and the plunger discharges the liquid in the upper chamber into the upper oil pipe of the pump. At the same time, the liquid in the well enters the lower chamber of the pump barrel through the fixed valve under the action of the inlet pressure. During the downstroke, the fixed valve is closed, the floating valve is opened, and the liquid in the lower chamber of the pump enters the upper chamber of the pump barrel through the inner cavity of the plunger. The plunger surges up and down, and the liquid is continuously pumped to the wellhead.

3. Analysis of the reasons for API tubing pump repair:

For coalbed methane wells, repair is mainly caused by eccentric wear and pump failure. Well repair requires all the pipes to be lifted out of the ground. There is a detailed description later.