The industry status of API tubing pump:

In the field of petroleum extraction, the rod pump oil recovery system has become the most widely used manual lifting method due to its high adaptability, simple structure and easy maintenance. As the core equipment of the system, API tubing pump occupies an important position. API tubing pump is manufactured in strict accordance with the standards set by the American Petroleum Institute (API), which makes API tubing pump highly versatile and interchangeable in the global oil extraction industry. Rod pumps and their components produced by different regions and manufacturers that meet API standards can be replaced with each other as long as the models and specifications match, which greatly improves the flexibility of equipment deployment and reduces maintenance and operating costs. For example, in large oil fields in the Middle East, the API tubing pumps used by many oil wells come from different suppliers, but they can all be seamlessly connected and work together in accordance with API standards.

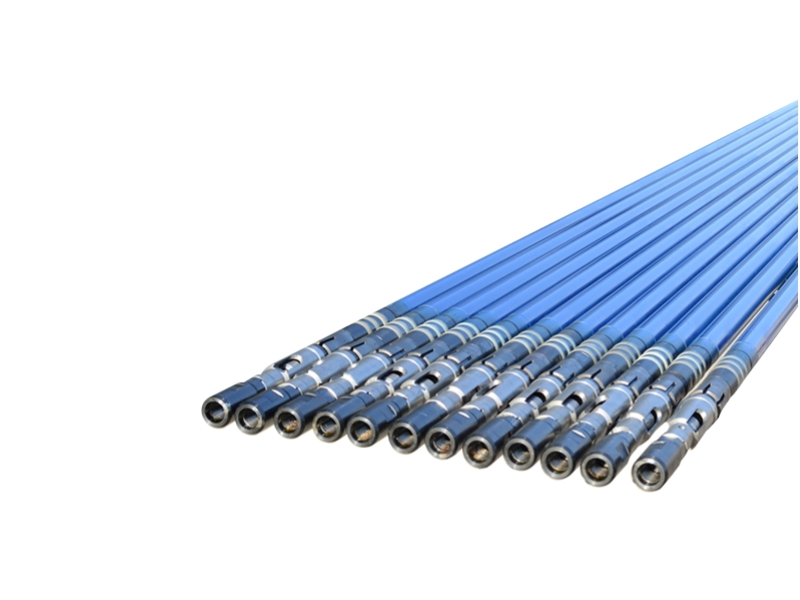

Rod pump (Insert Pump):

Rod pump, often called Insert Pump, is named because it needs to be inserted into the production tubing during operation. It is identified by the letter “R” in the API system.

RH rod pump: It is an underground pump with a thick-walled pump cylinder, which is suitable for deep well mining or harsh pumping environments such as fouling. Like RHA pumps, the pump barrel is fixed and the top is anchored. There are two configurations of cup holder assembly (RHAC) or metal seal (RHAM), which are suitable for medium-depth oil wells with fouling problems, sand-containing oil wells, and gaseous or foam-like oil wells with low liquid levels; RHB pumps are also fixed at the pump barrel, but the bottom is anchored, with corresponding cup holder assembly (RHBC) or metal seal (RHBM), which is more suitable for deep wells and low hydrostatic liquid level oil wells; RHT pumps are pump barrels that follow and the bottom is anchored, and there are also two sealing configurations. , Suitable for intermittent pumping oil wells and sand-containing oil wells.

RW rod pump: Thin-walled pump cylinder structure, suitable for medium-depth oil wells and large-yield oil wells. For example, RWA pumps, the pump barrel is fixed at the top and anchored, with a cup holder assembly (RWAC) or metal seal (RWAM), which can be used for large-production oil wells, sand-containing oil wells, and low-level gaseous or foam-like oil wells; RWB pumps are fixed at the bottom and anchor, and there are also different sealing configurations, which are suitable for large-production oil wells. Because of its bottom anchoring design, it is also suitable for relatively deep oil wells and oil wells with low hydrostatic liquid levels; RWT pumps follow the movement of the pump barrel and anchor at the bottom, which can be applied to large-production oil wells and oil wells with intermittent pumping. .

Tubular pump:

The working cylinder of the tubular pump is directly connected to the production oil pipe column. This connection method makes the tubular pump different from the rod pump in terms of structure and application scenarios. It is identified by the letter “T” in the API standard system. Tubular pumps are suitable for many different types of oil wells, especially in oil wells with large production, relatively stable well conditions and high pump displacement requirements. For example, in some high-yielding oil wells in eastern China, tubular pumps are widely used for crude oil extraction.

The structure and principle of API tubing pump:

Main structural components:

API tubing pump is mainly composed of pump cylinder, plunger, fixed valve (also known as suction valve), swimming valve (also known as discharge valve), and seat package device and other components. As a channel for the inhalation and discharge of crude oil, the pump cylinder, its material and manufacturing process directly affect the service life and performance of the pump; The plunger and the pump cylinder are closely matched, and the reciprocating movement is driven by the sucker rod to realize the pumping of crude oil; The fixed valve is installed at the bottom of the pump cylinder to control the suction of crude oil; the swimming valve is located above the plunger and is responsible for the discharge of crude oil; The seat package device is used to fix the pump in a predetermined position in the tubing to ensure the stability of the rod pump during work.

Explanation of working principle:

When the pumping unit drives the pumping rod to do the upper stroke movement, the pumping rod pulls the plunger to move upward. At this time, the space under the plunger in the pump cylinder increases and the pressure decreases. The fixed valve opens under the action of the pressure of the air-liquid column in the oil sleeve ring, and crude oil flows from the oil layer into the pump cylinder; At the same time, the swimming valve above the plunger is closed under the action of the pressure of the liquid column in the tubing, preventing the liquid from returning in the tubing. During the next stroke, the sucker rod pushes the plunger downwards, the pressure under the plunger in the pump cylinder increases, the fixed valve is closed, and the pressure above the plunger increases. When the pressure exceeds the pressure of the liquid column in the tubing, the swimming valve opens, and the crude oil in the pump cylinder is squeezed into the tubing, and so on. The cycle goes back and forth to achieve continuous lifting of crude oil from the bottom of the well to the ground.

Advantages of API tubing pump:

Adapt to various working conditions:

API tubing pump has a strong adaptability to different reservoir conditions and mining environments. Whether it is a conventional sandstone reservoir or a complex carbonate reservoir; whether it is a low-seepage, high-seepage reservoir, or a special oil well with high sand content, high gas content, and high water content, you can find a suitable AP rod pump model. For example, in high-sand oil wells, rod pumps with special sand-resistant structures can be selected, such as some RH and RW series pumps mentioned earlier. By optimizing the structure of the pump cylinder and valve, the wear of sand particles on the pump can be reduced to ensure the normal operation of the pump; In high-gas-to-oil ratio oil wells, tubular pumps can reasonably design the sinking degree of the pump and the gas separation device to reduce the impact of gas on pump efficiency and improve oil recovery efficiency.

Simple structure and easy to maintain:

Its structure is relatively simple, and the main components are clear and clear, which makes the installation, commissioning, repair and maintenance of the equipment easier. After simple training, the technical personnel on the oil extraction site can master the basic operation of API tubing pump and the troubleshooting and repair methods of common faults.When the pump fails, due to its simple structure, it can quickly locate the problem, replace the damaged parts in time, and resume production.Compared with some oil production equipment with complex structures, API tubing pump requires fewer professional tools and special technical requirements during the maintenance process, which greatly shortens the maintenance time, reduces the maintenance cost, and improves the production time rate of the oil well.

Application case of API tubing pump:

A large oilfield in the Middle East:

In a large oilfield in the Middle East with a daily output of more than 10,000 barrels of crude oil, API tubular pumps are widely used.The oilfield has a high permeability of the oil layer and good fluidity of crude oil, but the huge output requires strict pump displacement requirements.With its large pump diameter and high displacement characteristics, the tubular pump meets the needs of efficient oilfield mining.Long-term monitoring data show that the average operating efficiency of these API tubular pumps is as high as more than 85%, and the daily oil output of a single well is stable at a high level, which provides a solid guarantee for the high-yield and stable production of oil fields.At the same time, due to the unified specification of API standards, it is possible to quickly purchase adapted parts from all over the world during equipment maintenance and updates, greatly reducing equipment downtime.

A domestic low-seepage oilfield:

In a low-seepage oilfield in China, there are generally problems of low output and low liquid level in oil wells.In view of this situation, an API fixed-cylinder top fixed-rod pump (such as RHA type) was selected.The support sealing device of this type of pump is located at the top, which can effectively scour the sedimentation sand between the top and the tubing, and adapt to the relatively high sand content of low-seepage oil fields; moreover, the pump body can be rotated around the top fixing device, and it has good self-adjusting ability in inclined wells, which is in line with the characteristics of some oil wells in the oilfield as inclined wells. After application, the pump inspection cycle of the oil well has been extended from the original average of 3 months to more than 6 months, which greatly reduces the mining cost and improves the development efficiency of low-seepage oil fields.

References:

[1]"Downhole sucker-rod pumps". onepetro.org.

[2] "Rod pump technical Training Lecture Document".

[3]"Sucker Rod & Tubing Pumps - API Certified & Field-Proven".