08-19/2025

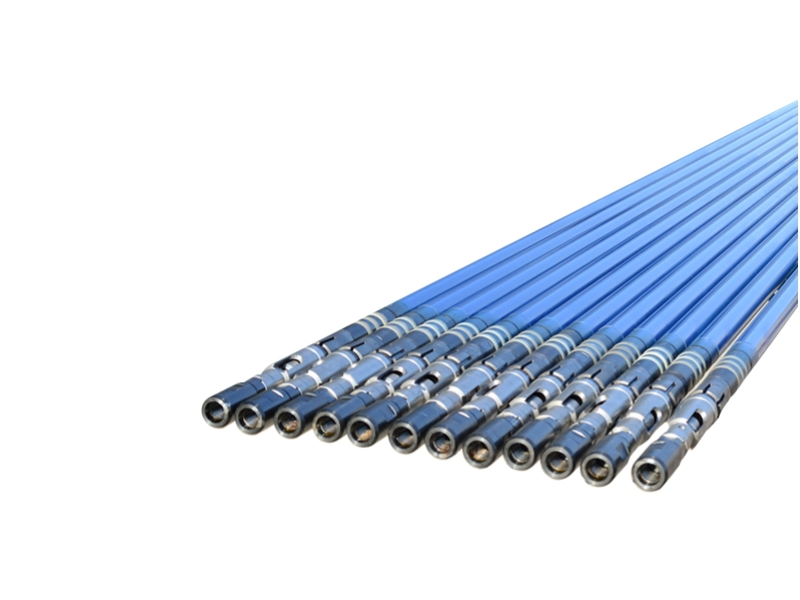

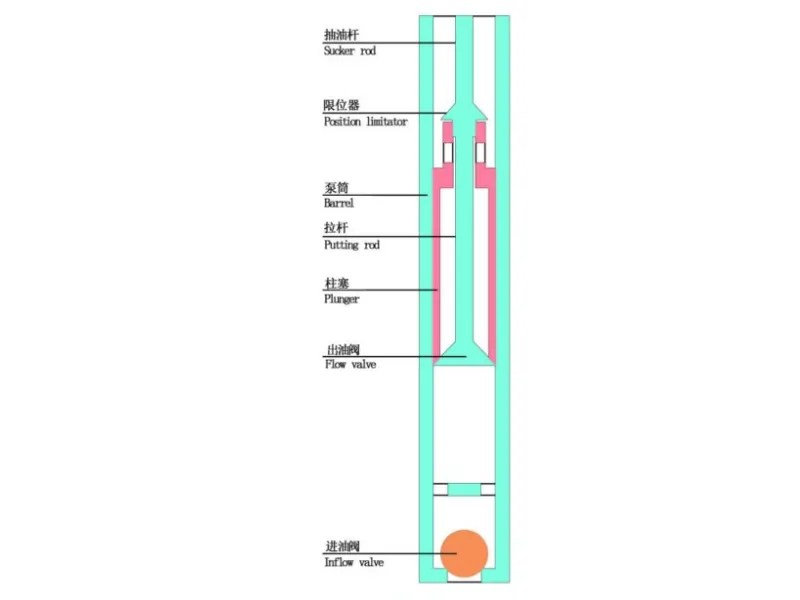

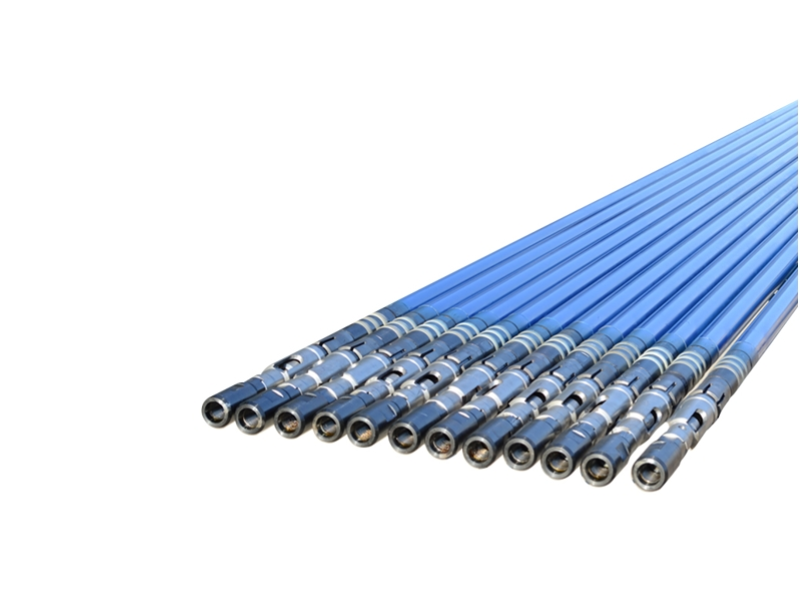

Oil recovery by rod pump is realized by a rod pumping system based on “three pumping” equipment (pumping unit, pumping rod and oil pump). That is, under the drive of the pumping unit, the plunger of the pumping pump (also known as the deep well pump) is driven up and down by the pumping rod going down into the well, and the well fluid is drawn to the ground.