In the global energy industry system, the efficiency and stability of oilfield extraction are directly related to the security of energy supply and the economic benefits of the industrial chain.However, the oilfield mining environment is complex and harsh, with high temperature, high pressure, high sulfur-containing media, and frequent wear and impact, making the core mining equipment face serious challenges. As an efficient equipment developed for extreme mining environments, RWA API Insert Pump are gradually becoming the mainstream choice in the field of oilfield mining due to their unique structural design and material advantages.

1. What is an RWA tubing pump?

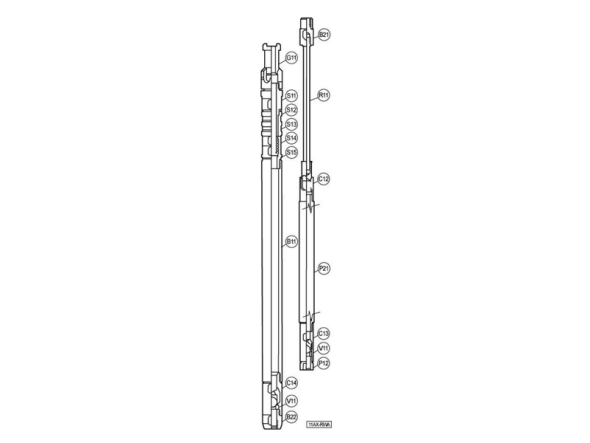

RWA tubing pump is a reciprocating oil recovery core equipment specially designed for complex oilfield mining scenarios. By improving the pump cylinder and plunger structure and innovating the surface treatment technology, it can realize the efficient extraction of high-sand, high-sulfur, and high-viscosity crude oil. Compared with traditional tubing pumps, RWA API Insert Pump use bimetal composite pump barrels-the inner layer is made of wear-resistant alloy material, and the outer layer is made of high-strength carbon steel to ensure compression resistance; the surface of the plunger is sprayed with nano-ceramic coating, which effectively reduces wear and loss. In addition, the RWA tubing pump is equipped with an adaptive sealing assembly, which can dynamically adjust the sealing strength according to the wellhead pressure to avoid media leakage and meet the needs of multi-scenario mining such as conventional oil fields and unconventional shale oil.

At present, RWA API Insert Pump have passed API Spec 11AX (American Petroleum Institute oil production Equipment standard) certification, and at the same time comply with the ISO 9001 quality management system and GB/T 28053-2011 "Oil and gas drilling equipment reciprocating pumping unit tubing pump" national standards, in terms of wear resistance, corrosion resistance and adaptability have reached the industry-leading level.

2. Product classification of RWA API Insert Pump:

According to the different needs of oilfield mining scenarios, RWA API Insert Pump can be divided into the following three categories, fully covering all kinds of mining conditions:

Conventional RWA tubing pump: Suitable for conventional crude oil extraction with medium and low viscosity and low sand content. It has a simple structure and easy maintenance. It is an economical choice for conventional oil fields on land. The average cost of adapting a single well is 15% lower than that of traditional high-end tubing pumps.

Sulfur-resistant and wear-resistant RWA tubing pump: The pump barrel is made of nickel-based alloy, and the plunger is sprayed with tungsten carbide coating. It can withstand acidic media with a volume fraction of HSS ≤20%. At the same time, the wear resistance of sand particles is greatly improved. It is designed for high-sulfur and high-sand oil fields, such as the acidic gas field in the Sichuan Basin and the high-sand oilfield in Karamay, Xinjiang. It is widely used.

3. Comparison of common equipment for oilfield mining:

In addition to RWA API Insert Pump, the core equipment commonly used in oilfield mining also includes traditional tubular pumps, screw pumps and electric submersible centrifugal pumps.There are significant differences in performance, cost and adaptation scenarios between different devices. The specific comparisons are as follows:

Device type adapts to media conditions, core application scenarios

Traditional tubular pumps for short-term mining of conventional shallow oil fields with low sand content, low sulfur content, medium and low viscosity crude oil

Screw pump high viscosity, high sand content crude oil heavy oil, high sand oilfield

Electric submersible centrifugal pump, low viscosity, low sand content crude oil, deep wells, large displacement oil fields

RWA tubing pump low-high viscosity, low-high sand content, low-high sulfur crude oil conventional oil fields, high sulfur oil fields, low-temperature deep wells, deep-sea oil fields

4. Market trends and sustainable development:

At present, global oilfield mining is transforming in the direction of “high efficiency, low carbonization, and intelligence”. On the one hand, the proportion of unconventional oil fields (such as shale oil and acid gas fields) mining continues to increase, and the weather resistance and adaptability of equipment are more demanding; on the other hand, oilfield companies have promoted “cost reduction and efficiency” and “green mining”, and the long life, low maintenance, and low energy consumption of equipment have become the core requirements.

The RWA tubing pump can be connected to the oilfield intelligent monitoring system, and the pressure, temperature and operating status of the pump body can be monitored in real time through sensors, so as to realize fault early warning and remote diagnosis, and help the intelligent transformation of the oilfield.

5. Precautions for the use of RWA API Insert Pump:

Pre-installation inspection: Before installation, it is necessary to confirm that the surface of the pump cylinder and plunger is free of scratches and rust, and the sealing components are intact; at the same time, the appropriate model is selected according to the wellhead pressure and medium composition to avoid equipment damage caused by mismatch.

Installation specifications: When installing, it is necessary to ensure that the pump body is perpendicular to avoid wear of the plunger caused by tilt; the connection parts need to be fastened to prevent leakage of high-pressure media; it is recommended to be operated by technicians with API certification qualifications.

Operation and maintenance: Check the operating status of the pump body regularly (every 3 months), and monitor changes in wellhead pressure and displacement. If the pressure is abnormal or the displacement drops, the wear of the sealing components and the pump cylinder must be checked in time; it is strictly forbidden to idlewild without media lubrication to prevent dry wear and tear.

Storage conditions: Unused RWA API Insert Pump should be stored in a dry and ventilated indoor environment; avoid mixing with acidic and alkaline substances to prevent material corrosion.

Adaptation to special working conditions: When used in high-sand oil fields, it is recommended to use a wellhead desanding device to reduce the entry of sand particles into the pump body; in a low-temperature environment, the sealing assembly needs to be preheated (temperature≥10℃) before installation to avoid low-temperature brittleness.

6. Conclusion:

In the context of the transformation of oilfield mining to high efficiency, low carbonization, and intelligence, RWA API Insert Pump have become an ideal choice to solve the pain points of traditional equipment and improve the efficiency of oilfield mining with their long life, multi-scene adaptation, and low maintenance costs.For oilfield companies pursuing “cost reduction and efficiency enhancement” and “green and sustainable”, the selection of RWA API Insert Pump can not only reduce the loss of production caused by equipment failure, but also reduce energy consumption and resource consumption, helping to achieve a win-win situation of economic and environmental benefits in the whole mining cycle.

7.Contact us:

Whether you are a conventional oilfield, a high-sulfur oilfield or a deep-sea oilfield, we can provide customized RWA tubing pump solutions according to your mining conditions, including equipment selection, installation guidance, intelligent monitoring system adaptation and other full-process services. If you need to obtain product samples, technical parameters or on-site trial, please contact us through the following methods:

Email:jason@tldspm.com

Telephone: +86-13052798822

Official website:https://www.dsrodpump.com /(Requirements can be submitted online and technical response can be obtained within 24 hours)

We sincerely invite oilfield mining companies and petroleum equipment distributors to work together to jointly promote the upgrading and green development of oilfield mining equipment and create new value in the energy industry!

8. References:

1.International Energy Agency (IEA)."Global Energy Equipment Reliability Report (2023)"

2."Global Oil Drilling Equipment Market Report (2024-2030)"

3.National Standardization Administration. "Oil Pipe pump for Reciprocating Pumping Unit of Oil and Gas Drilling and Production Equipment"

4.China Petroleum Society. "Technical White Paper on Unconventional Oilfield Mining Equipment (2024)"

5.International Organization for Standardization (ISO) "Specification for Corrosion-resistant Alloy Pipes in the Oil and Gas Industry"