The most commonly used deep well pump oil recovery device is a beam-type oil pump-oil pump device, which includes a pumping unit, the ground part of the wellhead device of the pumping well, and the underground part including the pumping rod, the oil pump, and the oil pipe. Among them, the pumping unit, the pumping rod, and the oil pump are the most important components of this kind of oil pumping device, the so-called “three pumping equipment.”

1.Pumping unit:

The oil pumping unit is a ground mechanical transmission device for pumping oil wells. It is used in conjunction with the oil pumping rod and the oil pump to pump underground crude oil to the ground. Due to the different structure and working principle of the pumping unit, it can be divided into beam-free pumping unit and beam-free pumping unit. According to the different structures of the beam pumping unit, it is generally divided into ordinary type and forward type (front type). The ordinary bracket is between the donkey head and the crank connecting rod mechanism, and the forward crank connecting rod mechanism is located between the donkey head and the beam bracket.

The working principle of the oil pumping unit is that the motor transmits its high-speed rotational movement to the output shaft of the gearbox, and after passing through the intermediate shaft, it drives the output shaft, and the output shaft drives the crank for low-speed rotational movement. At the same time, the crank is pulled by the rear arm of the beam through the connecting rod to swing the rear arm of the beam. The front end of the beam is equipped with a donkey head, and the loads such as the liquid column above the piston and the sucker rod column are all suspended on the donkey head through a rope suspender. Since the donkey head swings up and down with the travel beam, the travel beam donkey head drives the piston to reciprocate up and down, vertically, and draws the oil out of the well.

2.Oil pump:

A pumping pump, also known as a deep well pump, is a special equipment for mechanical oil production with a rod. The pump is located at a certain depth below the moving liquid level in the well shaft and relies on the pumping rod to transmit the power of the pumping machine to pump crude oil out of the ground. Due to the different installation methods in the well, it can be divided into two types: tubular pumps and rod pumps. More on-site applications are tubular pumps.The tubular pump has a large diameter, large displacement, simple structure and low price. It is suitable for wells with high output, shallow oil wells, more sand, and small gas volume; the rod pump has a small diameter, low displacement, and easy pump inspection. It is suitable for deep wells with low output.

The working principle of the oil pump is that the pumping unit on the ground drives the piston of the pump up and down through the pumping rod, continuously pushing the oil to the ground. A single upward and downward movement of the pump is called a stroke, and the discharge volume of a stroke is theoretically equal to the volume given up by the upward movement of the piston of the pump.In fact, the production of pumping oil wells is affected by various factors. The amount of liquid produced by the oil well is not equal to the theoretical displacement. The ratio of the actual liquid produced by the pumping oil well to the theoretical displacement of the pump is called the pump efficiency. The pump efficiency of the pumping unit is an important management index.

There are three factors that affect the efficiency of the pump:

(1) Geological factors, such as oil well sand output, the influence of gas, oil well waxing, the high viscosity of crude oil, and the corrosive water and gas contained in crude oil.

(2) The manufacturing and installation quality of the pump.

(3) Selection of working parameters of the pump.

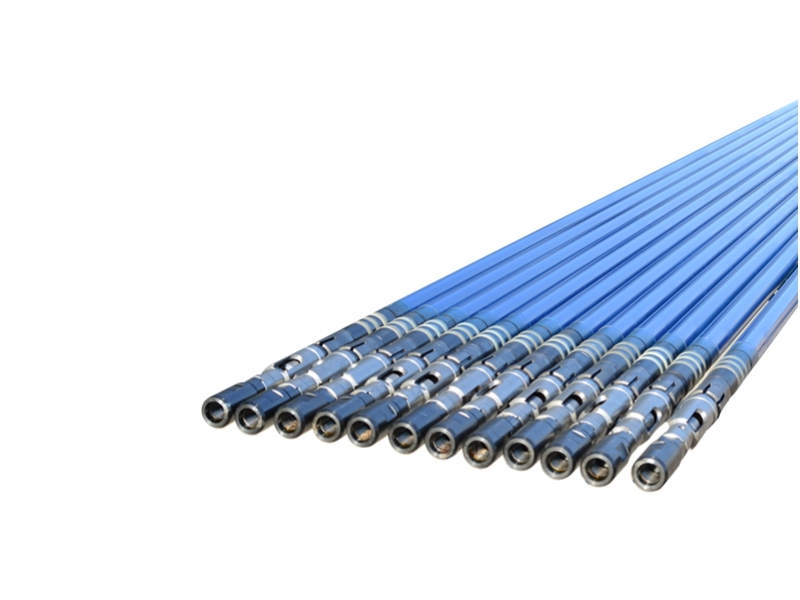

3. Sucker rod:

The oil pumping rod is an important part of the oil pumping device of a rod pump. The power of the oil pumping machine is transmitted to the oil pumping pump through the oil pumping rod column, so that the piston of the oil pumping pump reciprocates. The main body of the oil pumping rod is a solid rod with a circular cross-section. Carbon steel oil pumping rod and alloy steel oil pumping rod are currently used.

In the oil production process, generally we have these three kinds of equipment to complete the complete oil production process. For these three kinds of equipment, each of them is an indispensable device.