06-30/2025

Sucker Rod Pump Technical Standards:

1. Sucker rod pump parts materials and processes:

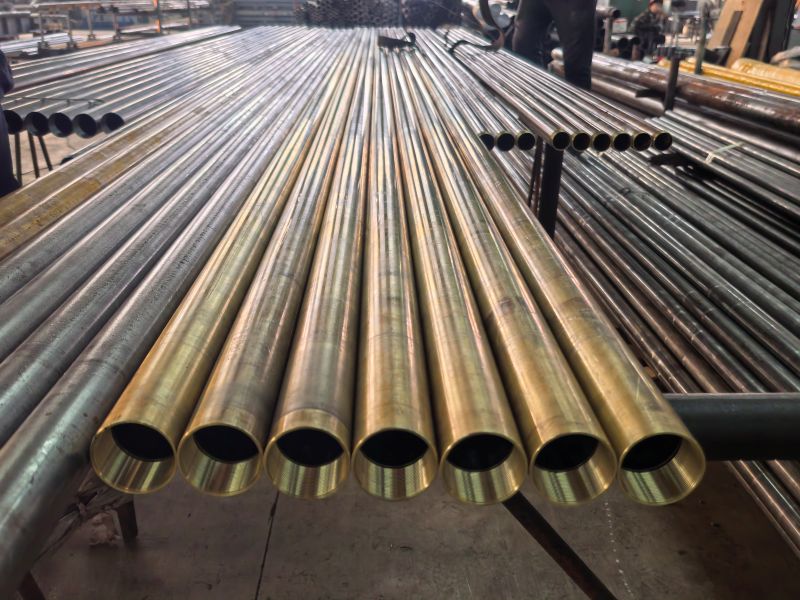

Pump Barrel:

Sucker rod pump barrel hardening methods: chrome plating, carburizing.

Chrome-plated pump barrel basic materials: 1045, 1026, 4140, 4/6 chrome steel, C44300.

Carburized pump barrel basic materials: 1020 steel.

Pump barrel maximum length: 35ft.

Chrome plating hardness: HV100900~1160.

Carburizing hardness: minimum hardness 690 Knoop at 0.005in from the single edge surface, minimum hardness 466 Knoop at 0.010in from the single edge surface.

Plunger For Oil Well:

Plunger hardening method: alloy powder spray welding, chrome plating.

Spray welding layer hardness: ≥HV200595.

Chrome plating hardness: HV100832~1160.

Various lengths of plungers can be manufactured according to user requirements, with a maximum length of 41ft.

Parts: API standard whole-barrel pump, rod pump, moving barrel pump accessories; monel alloy lined valve cover; rubber lined valve cover,

Parts materials include: carbon steel, low alloy steel, stainless steel, nickel-copper alloy, brass

Valve pair:

Valve pair materials include: stainless steel; cobalt-chromium-tungsten alloy; tungsten carbide; titanium carbide; nickel carbide.