1. Core structure differences:

The tubular pump cylinder adopts a single-cylinder integrated structure, and the whole is a seamless steel pipe (whole cylinder type) or outer pipe + inner liner (combined type), which is directly fixed to the lower end of the tubing as an extension of the tubing, without additional nested parts. Rod pump barrels are nested structures with inner and outer double cylinders. The outer cylinder is the basic carrying cylinder and goes down into the well with the tubing; the inner cylinder is the core working cylinder, which needs to be suspended and fixed by the sucker rod on the tapered lock in the outer cylinder. The double-layer cylinder body forms an independent working space, which is the most essential structural difference between the two.

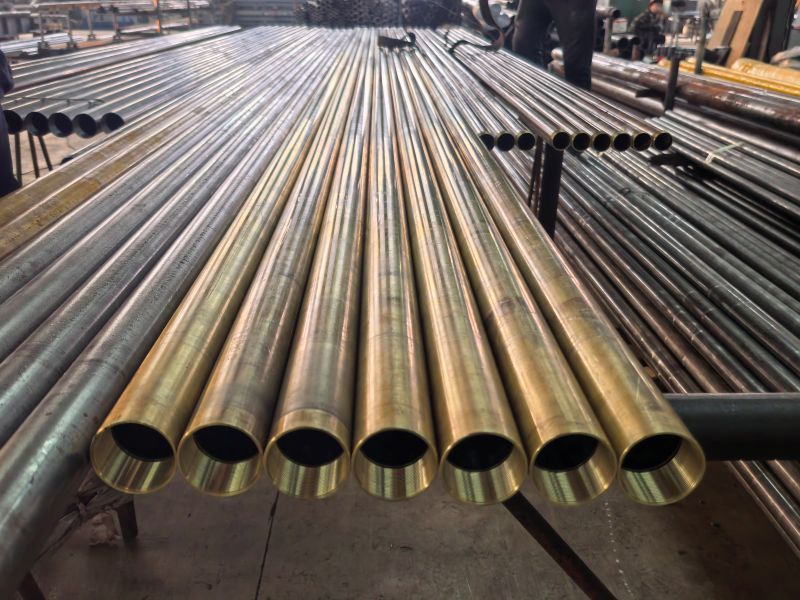

2. Differences in material and processing technology:

The tubular pump cylinder (whole cylinder type) is mostly made of high-hardness alloy steel pipes, which are directly formed by precision boring, and the inner wall needs to be chrome-plated or nitrided to improve wear resistance; the combined tubular pump cylinder is the outer tube with a wear-resistant bushing, and the accuracy of the inner wall is processed as a whole after assembly.Rod pump barrels have higher material requirements. The outer cylinder needs to withstand downhole pressure and impact, and high-strength seamless pipes are selected. Due to frequent disassembly and assembly of the inner cylinder, in addition to the strengthening of the inner wall, both ends of the cylinder body also need to be processed to adapt to the circlip locking groove, the machining accuracy requirements are 2-3 levels higher than that of the tubular pump cylinder.

3. Difference in connection method with tubing:

The tubular pump cylinder and the oil pipe are directly rigidly connected, and the two ends of the cylinder body are threaded with oil pipes, which can be directly docked with the upper and lower oil pipes. When installed, it will go down with the oil pipe column as a whole, without the need for additional fixed structures. Rod pump barrels The inner and outer cylinders are rigidly connected to the tubing, while the inner cylinders are not in direct contact with the tubing. They are only suspended inside the outer cylinder through the sucker rod, relying on the circlip mechanism in the outer cylinder for positioning, and there is no direct connection with the tubing. Relationship.

4. The size of the cylinder body is related to the adaptation of the displacement:

Under the same tubing specifications, the tubular pump cylinder has no outer cylinder restrictions, and the inner diameter of the cylinder body can be maximized. For example, the inner diameter of the tubular pump cylinder supporting the 73mm tubing can reach 56mm, which can be adapted to larger diameter pistons and indirectly increase the displacement. Rod pump barrels are restricted by the inner diameter of the outer cylinder. The inner diameter of the inner cylinder needs to be smaller than that of the outer cylinder. For example, the inner diameter of the outer cylinder of rod pump barrels supporting the 73mm tubing is about 65mm, and the inner diameter of the inner cylinder can only be designed to be 44-50mm. The diameter of the adapted piston is smaller, and the displacement adaptation capacity is weaker than that of the tubular pump cylinder.

5. Differences in disassembly and assembly during maintenance and overhaul:

During the maintenance of the tubular pump cylinder, it needs to be lifted out with the tubing column as a whole. Because it is directly connected to the tubing, it cannot be disassembled separately. The entire string of tubing needs to be processed during the lifting process, resulting in a large amount of disassembly and assembly of the pump cylinder during the maintenance, which takes a long time.During the maintenance of rod pump barrels, only the inner cylinder needs to be raised separately, and the outer cylinder can be left in the well. The inner cylinder can be removed from the outer cylinder through the sucker rod. There is no need to move the oil pipe. The disassembly and assembly efficiency of the pump cylinder is 3-4 times higher than that of the tubular pump cylinder.

6. The difference between the stability of the cylinder body and the adaptation of the underground environment:

Due to the integrated structure of a single cylinder, the tubular pump cylinder is rigidly connected to the oil pipe. In shallow wells, it is less affected by the bending of the well body, and the cylinder body has strong stability and is not easy to shift.The inner cylinder of rod pump barrels is suspended installation. In deep wells, the outer cylinder can be slightly deformed with the well body. The inner cylinder relies on the positioning of the sucker rod, which can reduce the extrusion deformation of the cylinder body by the pressure of the deep well, and the stability is more suitable for the deep well environment than the tubular pump cylinder.

7. Advantages of rod pump barrelsin shallow and deep wells:

Because of its large inner diameter characteristics, rod pump barrels are suitable for the needs of high-yield mining in shallow wells. The structure directly connected to the tubing is in a shallow conventional pressure environment. The cylinder body has low wear and long service life, which can reduce the displacement loss caused by the size restriction of rod pump barrels; The double-barrel structure of rod pump barrels has significant advantages in deep wells. The outer cylinder can withstand deep well pressure, and the inner cylinder can be flexibly disassembled and assembled without the need for oil pipes, which can reduce the risk of deep well operations. At the same time, the small inner diameter of the inner cylinder is designed to adapt to the flow requirements of low-yielding wells and avoid the loss of displacement caused by excessive displacement. Waste of resources.