Oil recovery is a complex process that varies depending on the environment. The three main environments for oil recovery are onshore, offshore, and unconventional reservoirs. Today we will talk about what kind of sucker rod pump should be used for onshore oil recovery.

Onshore oil recovery refers to the extraction of oil from reservoirs below the surface on land. This environment has several distinct characteristics:

1. Accessibility: Onshore reservoirs are generally easier to exploit than offshore or unconventional reservoirs. This accessibility facilitates drilling, well construction, and maintenance.

2. Environmental impact: Onshore drilling affects local ecosystems and communities. It is critical to mitigate these impacts through responsible environmental practices and regulations.

Onshore oil recovery methods:

Onshore oil recovery mainly involves conventional methods: Primary recovery: This initial stage relies on natural reservoir pressure to press the oil to the surface. The main onshore method usually involves drilling vertical wells in conventional reservoirs. Secondary recovery: When the primary method is no longer effective, secondary methods such as water injection or gas injection can be used to maintain reservoir pressure and increase recovery.

Take the tubing pump recommended by our company and widely used as an example, the main technical parameters of the TH tubing pump are as follows:

Pump barrel diameter: 2.25 inches.

Plunger stroke: 144 inches.

Applicable well depth: up to 3000 meters.

Theoretical displacement: about 3.8 m³/d (6 strokes/minute).

Applicable liquid: medium and low viscosity crude oil.

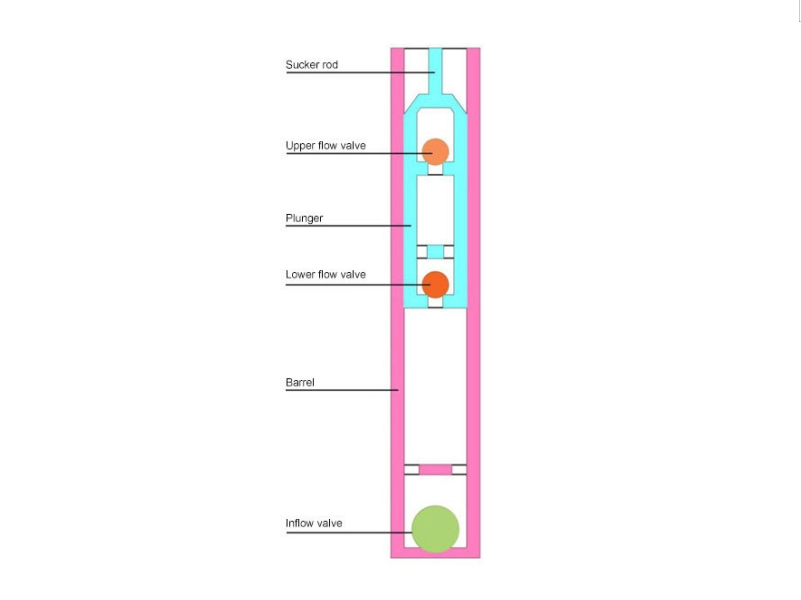

TH tubing pump adopts the basic structure of fixed pump barrel and reciprocating plunger, and is installed inside the oil pipe. Due to its compact structure and strong versatility of parts, tubing pump is particularly suitable for onshore oilfield applications with a high degree of standardization.

Analysis of reasons for tubing pump application in onshore oilfields:

1. Reliable structure and easy maintenance.

The operating conditions of onshore oilfield drilling platforms are relatively loose, which can meet the operating requirements of the whole pump running in and out. TH tubing pump adopts an integral structure, and there is no sealing instability problem caused by the floating pump barrel, so the operation is more reliable and suitable for oil wells with a long maintenance cycle.

2. High displacement to match the needs of medium and high-yield oil wells.

TH tubing pump has a large effective volume, and the displacement can be flexibly adjusted by increasing the plunger stroke or the number of strokes. According to our actual application cases in onshore oil fields in the northwest and northeast, TH tubing pump can maintain a stable production of 3-5 cubic meters/day for a long time under the conditions of medium-deep wells (1200-2500 meters), especially suitable for maintaining production capacity after entering the secondary recovery stage.

3. Tubing pump accessories are produced in a standardized manner, suitable for batch deployment.

TH tubing pump products provided by our company all comply with API 11AX standards, and accessories such as pump barrels, plungers, and valve groups are easy to replace and have strong versatility. In batch deployment in multiple oil fields, we have effectively reduced customers' procurement and operation and maintenance costs through standardized product selection and unified spare parts management.

4. Stable operation, adapting to reservoir life cycle management.

The production of onshore oil fields usually goes through a transition period from high-pressure self-spraying to mechanical lifting. TH tubing pump, due to its large displacement, high operating efficiency, and low energy consumption, can well adapt to the production characteristics of the early and middle stages of reservoir development. In addition, by simply adjusting the plunger stroke, tubing pump can adapt to oil wells with different production capacity states, and has good life cycle compatibility.

Application case:

In a large onshore oil field in northwest my country, our company configured TH tubing pump for customers and put it into use in more than 40 medium-deep wells. The average operation cycle exceeded 18 months, the equipment was highly stable, and the cumulative number of well shutdowns was significantly less than the plunger pump system previously used by the customer. This case proves that TH tubing pump is not only reliable in operation in typical onshore application environments, but also has excellent adaptability and economy.

The production stability and operational efficiency of onshore oil recovery are inseparable from reliable lifting equipment. We will continue to provide oil pumps for different development stages and reservoir conditions based on actual customer needs and field data.

If you need further tubing pump samples or technical selection suggestions, please contact us for professional advice