In simple terms, the stroke length is the maximum straight distance for the plunger of a rod pump to move up and down in the pump cylinder, just like the moving distance of the syringe push rod from fully pressed in to fully pulled out, which is directly related to the amount of oil recovered in a single time. The API 11AX Tubing Pump, which meets international standards, is becoming a favorite device for domestic and foreign websites through its precise stroke length design.

The stroke length is not arbitrarily set, and it needs to match the actual needs of the oilfield.Low-permeability oil wells are suitable for short-stroke to avoid damage to the formation, while high-yield oil wells require long-stroke to improve efficiency. However, no matter what kind of working conditions, API 11AX Tubing Pump can achieve optimal results through flexible adaptation-its stroke length design strictly follows the API Spec 11AX standard formulated by the American Petroleum Institute (API). This specification makes clear requirements from material, structural accuracy to performance testing, making API 11AX Tubing Pump stable under different well conditions and stroke adaptability, which is also one of its core advantages.

Taking the ultra-long-stroke oil production equipment used in a domestic oilfield as an example, after this project adopts API 11AX Tubing Pump technology, the stroke length can reach 30-50 meters, which is 10-17 times that of conventional rod pump equipment. With the design of ultra-low impulse times (reciprocation times per minute), the oil recovery efficiency of the system is directly increased by 15-20%, and the power saving rate reaches 40-60%. This high-efficiency mode of ”long stroke + low impulse" is perfectly reflected in the API 11AX Tubing Pump, which not only reduces equipment fatigue and loss, but also reduces the energy consumption of oilfield production.

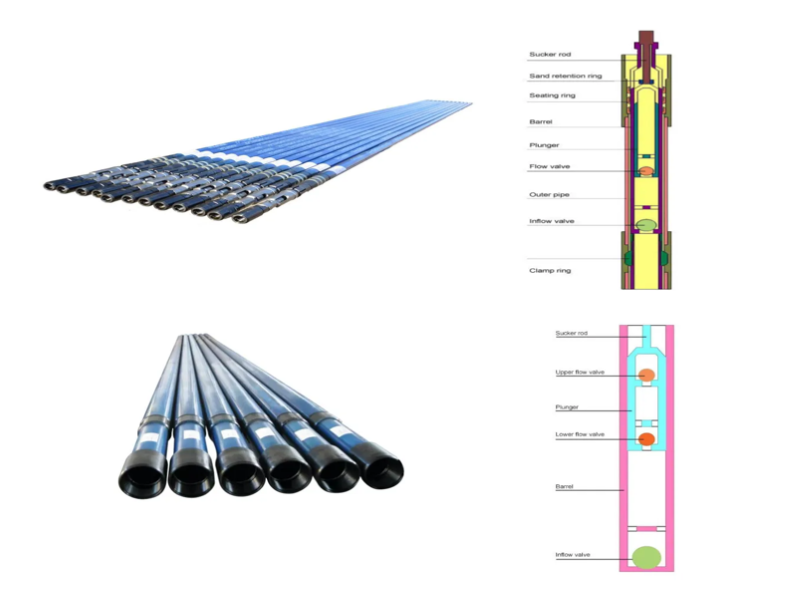

The precise control of the stroke length is inseparable from good equipment support. API 11AX Tubing Pump treats the inner wall of the pump barrel through a special chrome-plated process, and cooperates with the precision-ground plunger design to make the coaxiality error between the pump barrel and the plunger less than 0.03mm, reaching the level 1 clearance level standard.This high-precision cooperation allows the stroke length to be fully utilized, avoids crude oil leakage caused by excessive clearance, and reduces invalid motion loss. At the same time, the core components of API 11AX Tubing Pump are made of corrosion-resistant alloy materials, which can withstand high temperatures above 120℃ underground and corrosion of sulfur-containing media. Even in sand-containing oil wells, a reasonable stroke length design can reduce rod and pipe wear and extend the pump inspection cycle by more than 30%.

In practical applications, the stroke length advantages of API 11AX Tubing Pump continue to be prominent. After popularizing API 11AX Tubing Pump-related technologies in large domestic oil fields such as Daqing Oilfield and Changqing Oilfield, not only has the frequency of auxiliary operations such as oil well dosing and hot washing been reduced, but also through the precise matching of stroke length and oil well production capacity, the daily output of a single well has been increased and the comprehensive production cost has been reduced. The dual benefits. This adaptability allows API 11AX Tubing Pump to not only meet the conventional oil production needs of shallow wells (well depth <1500 meters), but also to meet the complex challenges of deep and high-pressure reservoirs (well depth >3000 meters), and the installation and maintenance process is standardized, greatly reducing equipment downtime.

For oilfield production, understanding the meaning of stroke length is the first step in choosing the right equipment. The API 11AX Tubing Pump, with its standardized design, flexible stroke adaptation ability and significant energy-saving effect, is becoming the key to unlocking efficient oil recovery. Whether it is to improve pump efficiency or reduce costs, API 11AX Tubing Pump uses practical application data to prove that precise control of stroke length and relying on compliance and reliable equipment can maximize the value of each oil well.

For oilfield production, understanding the meaning of stroke length is the first step in choosing the right equipment, and choosing a professional and reliable equipment supplier is also critical.As an enterprise focusing on the research and development and sales of petroleum rod pumps and pipe pumps, Dongsheng Petroleum has always taken API standards as its core. The API 11AX Tubing Pump produced not only strictly complies with the API Spec 11AX specification, but also provides customized solutions according to the travel length requirements of different oil fields. Provide technical support from equipment selection to on-site adaptation, help oil fields achieve efficient and energy-saving oil production goals, and inject reliable power into the development of the industry.