Table of contents:

Structural design

Applicable scenarios

Performance parameters

Selection suggestions

Service guarantees

Reference materials

In oil extraction equipment, tubing pump and rod pump are two mainstream types of manual lifting equipment. Although they belong to the same category of oil pumps, there are significant differences in structural design, applicable scenarios and performance. As an enterprise focusing on the research and development of petroleum extraction equipment, Tieling Dongsheng has deeply cultivated the API standard system. The APl rod pump we produce has become the preferred equipment for many oil fields due to its compliance and adaptability.

Structural design:

Tubing pump adopts the structural design of “tubing carrying + overall lifting and lowering". The pump body is rigidly connected to the tubing. When working, it needs to go down into the well with the tubing as a whole, and all the tubing needs to be lifted out during maintenance. The operating time of a single well is usually 8-12 hours. Its core components include the outer cylinder, bushing and piston, which rely on the tubing to transmit power, so the verticality of the tubing is more demanding.

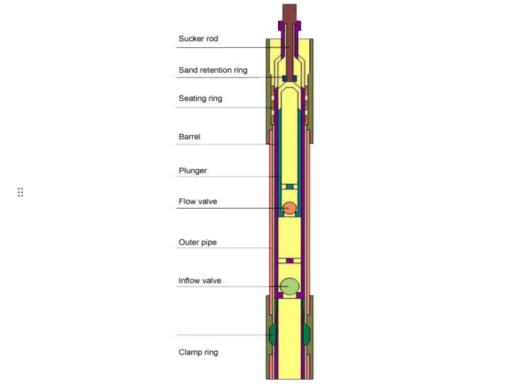

The APl rod pump adopts a “sucker rod drive + split structure". The pump barrel is fixed to the oil pipe, and the plunger transmits power up and down through the sucker rod. During maintenance, only the sucker rod and plunger need to be removed, and the operating time can be shortened to 3-4 hours. According to the API 11AX standard, the gap between the plunger of APl rod pump and the pump cylinder needs to be controlled at 0.03-0.08mm, which can make it efficient to seal and reduce wear. Tieling Dongsheng's APl rod pump has improved the connection structure on this basis, using a high-strength alloy steel sucker rod and an anti-release coupling to reduce the fracture rate of the rod and column by more than 30%.

Applicable scenarios:

Tubing pump is more suitable for shallow wells (≤1500 meters) and low-sand reservoirs. Because of its strong structural integrity, it performs stably in well conditions with straight well body trajectories. However, in deep wells, inclined wells, or wells with high sand content, the limitations of tubing pump are obvious-the expansion of the tubing can easily cause the pump body to wear out, and the deposition of sand particles will also exacerbate the wear of the bushing.

APl rod pump shows stronger environmental adaptability: in wells with a depth of 2000-3500 meters, its graded bearing design can disperse the rod and column loads; In directional wells with a slope of ≤30°, the flexible connection structure can reduce partial wear; For reservoirs with a sand content of ≤2%, APl rod pump is equipped with sand-proof Verne, which can effectively block sand particles from entering the pump cylinder.

Performance parameters:

In terms of displacement, the single-cylinder displacement of the tubing pump is large (10-50m3/d), but it is limited by the inertia of the tubing movement, and the stroke is usually ≤6 times/min; Although the single-cylinder displacement of the APl rod pump is small (5-30m3/d), the stroke can reach more than 10 times/min, and the equivalent displacement is achieved through high-frequency reciprocation, which is more suitable for fine mining of low-permeability reservoirs.

In terms of energy consumption performance, APl rod pump has significant advantages. According to the test data of "Petroleum Machinery", under the same well depth and production conditions, the unit energy consumption of APl rod pump is 18-25% lower than that of tubing pump, thanks to its lightweight rod and column design and improved hydraulic loss structure.

Tieling Dongsheng's APl rod pump has further improved its performance through material upgrades: the pump barrel is chrome-plated with 42CrMo, and the surface hardness reaches HRC60; The plunger is made of bimetal composite materials, which can maintain dimensional stability at a high temperature of 200℃. These indicators meet the strict requirements of API 11AX.

Selection suggestions:

When choosing tubing pump or APl rod pump, factors such as well depth, sand content, and crude oil viscosity need to be considered comprehensively: when shallow wells, straight wells, and the medium is clean, tubing pump is an economical choice; under deep wells, inclined wells, or complex media conditions, APl rod pump can better guarantee long-term stable operation.

Service guarantee:

As an API certified company, Tieling Dongsheng can provide customers with customized solutions, including improving the stroke, stroke and material configuration of APl rod pump according to reservoir parameters, and providing on-site installation guidance. At present, our APl rod pump has served a number of major domestic oil fields and exported to Kazakhstan, Iraq and other overseas markets, winning wide recognition for its reliable performance.

Understanding the differences between tubing pump and rod pump is a prerequisite for efficient mining. Tieling Dongsheng APl rod pump provides petroleum companies with trustworthy manual lifting solutions with advanced design, compliance standards and empirical results.

Reference materials:

[1] American Petroleum Institute. API 11AX Specification for sucker - rod pumps [S].

[2] Test data of "Petroleum Machinery"